Positive electrode material of polypyrrole lithium sulfur battery and preparation method of positive electrode material

A cathode material, lithium polypyrrole technology, applied in battery electrodes, circuits, electrical components, etc., to achieve high capture capacity, improved energy density and cycle performance, and good reversibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

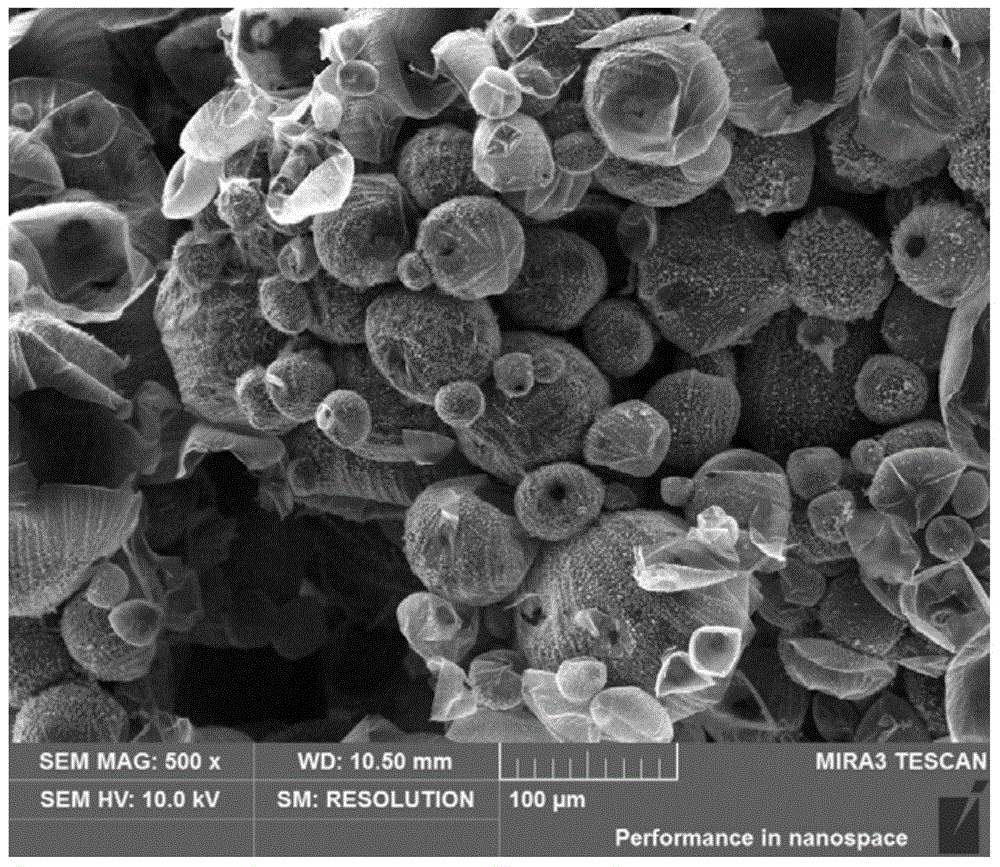

Image

Examples

Embodiment 1

[0040] Weigh 0.700 g of p-toluenesulfonic acid and dissolve in 30 mL of deionized water. After magnetic stirring for 3 minutes, weigh 0.200 g of sodium dodecylbenzene sulfonate, add sodium dodecylbenzene sulfonate to the above aqueous solution while maintaining magnetic stirring, and continue stirring for 5 minutes. Then add 0.2 mol of the pyrrole monomer that has been distilled twice with a needle, stir it magnetically for 3 minutes, and ultrasonically shake for 5 minutes to obtain the electrolyte required for electrochemical synthesis, pH=1~2, and let the electrolyte stand for 10 minutes for use.

[0041] Pretreatment of working electrode and counter electrode. The tantalum electrode and the stainless steel electrode are treated with hydrochloric acid, ethanol, and acetone in sequence before use. The purpose is to remove organic matter such as grease on the electrode surface. Before using the tantalum electrode, the side facing the stainless steel electrode is pasted with tran...

Embodiment 2

[0050] Weigh 0.700 g of p-toluenesulfonic acid and dissolve in 30 mL of deionized water. After magnetic stirring for 3 minutes, weigh 0.250 g of sodium dodecylbenzene sulfonate, add sodium dodecylbenzene sulfonate to the above aqueous solution while maintaining magnetic stirring, and continue stirring for 5 minutes. Then add 0.2 mol of the pyrrole monomer that has been distilled twice with a needle, magnetically stir for 3 minutes, and ultrasonically shake for 5 minutes to obtain the electrolyte required for electrochemical synthesis, pH=2.0-3.0. The electrolyte is allowed to stand for 10 minutes for use.

[0051] Pretreatment of working electrode and counter electrode. The tantalum electrode and the stainless steel electrode are treated with hydrochloric acid, ethanol, and acetone in sequence before use. The purpose is to remove organic matter such as grease on the electrode surface. Before using the tantalum electrode, the side facing the stainless steel electrode is pasted wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com