Rare earth metal organic framework material with high quantum yield and preparation method thereof

An organic framework, rare earth metal technology, applied in the field of optical materials, can solve the problems of light emission easily affected by the environment, difficult to apply red light, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

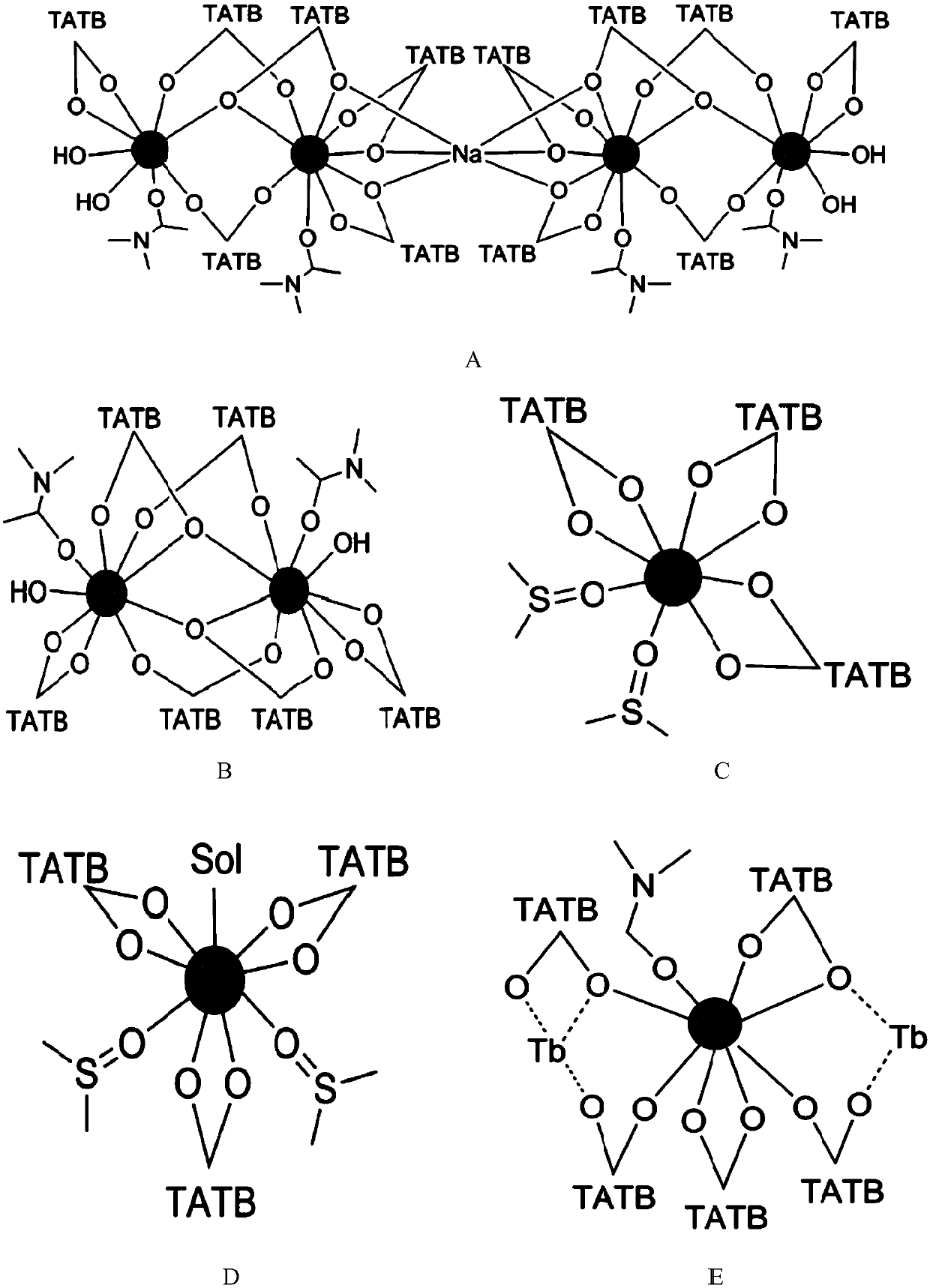

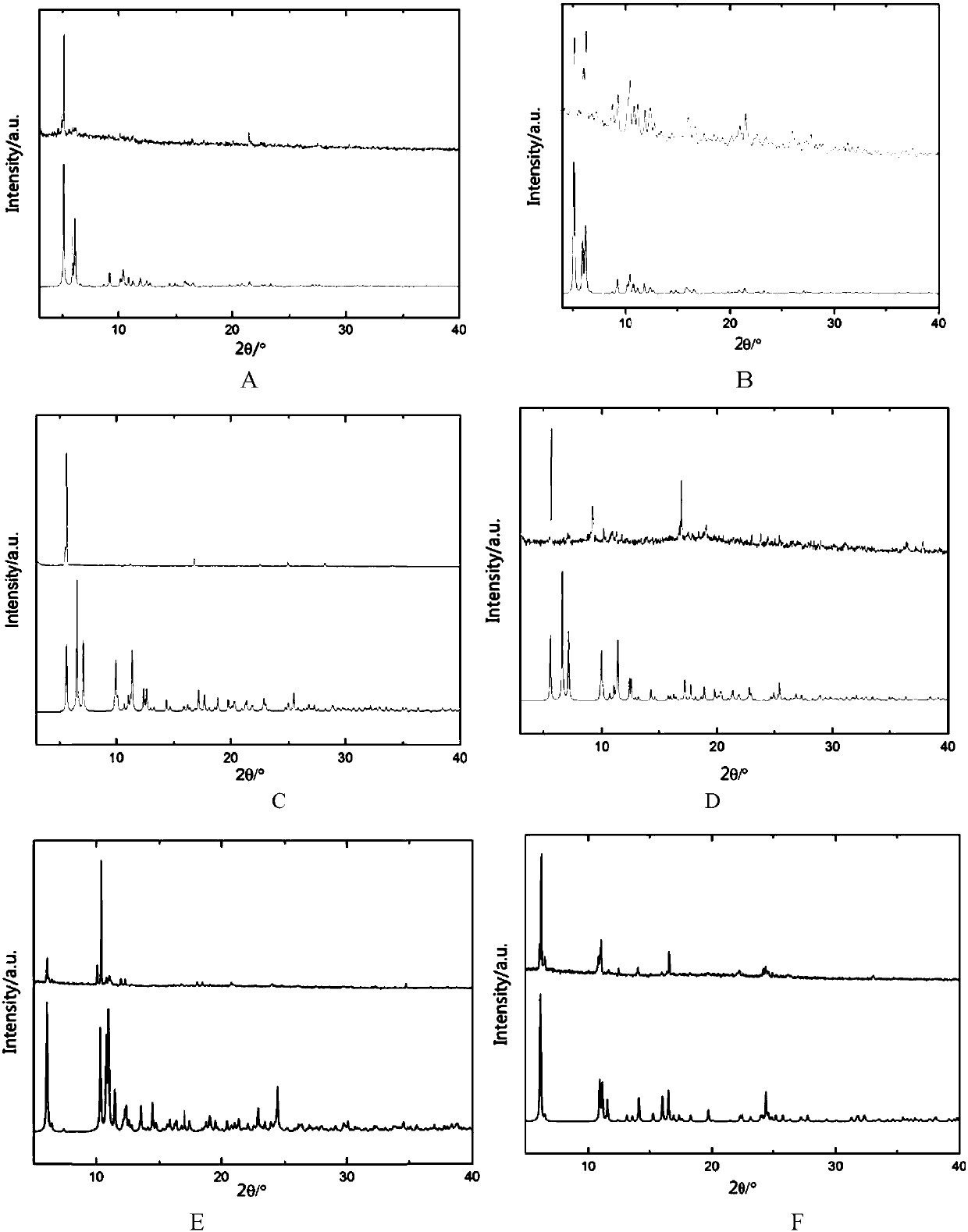

[0079] Embodiment 1 LMOF-1 synthetic method

[0080] Synthesis method of LMOF-1-Eu: 0.02 g ligand H 3 TATB (0.01 g of sodium nitrate can be added if the ligand removes a little salt impurity), 0.02 g of europium nitrate hexahydrate is added to a glass vial containing 4 ml of N,N dimethylacetamide solvent, and ultrasonicated for fifteen Minutes, add 0.2 ml of deionized water, and put it into a 120 degree oven for two days to react to obtain the desired material single crystal, with a yield of 0.021 g and a yield of 49%.

[0081] LMOF-1-Tb synthesis method: replace europium nitrate hexahydrate with terbium nitrate hexahydrate in the above method, and the rest are the same.

Embodiment 2

[0082] Embodiment 2 LMOF-2 synthesis method

[0083] Synthesis method of LMOF-2-Eu: 0.02 g ligand H 3 TATB, 0.02 grams of europium nitrate hexahydrate was added to a glass vial containing 4 milliliters of N,N dimethylacetamide solvent, ultrasonicated for 15 minutes, placed in an oven at 105 degrees Celsius, and 0.2 milliliters of deionized water was added after one day of reaction, and then in A single crystal of the desired material can be obtained after one day of reaction at 105 degrees Celsius. Yield 0.026 g, 67% yield.

[0084] LMOF-2-Tb - Synthetic method: replace europium nitrate hexahydrate with terbium nitrate hexahydrate in the above method, and the rest are the same.

Embodiment 3

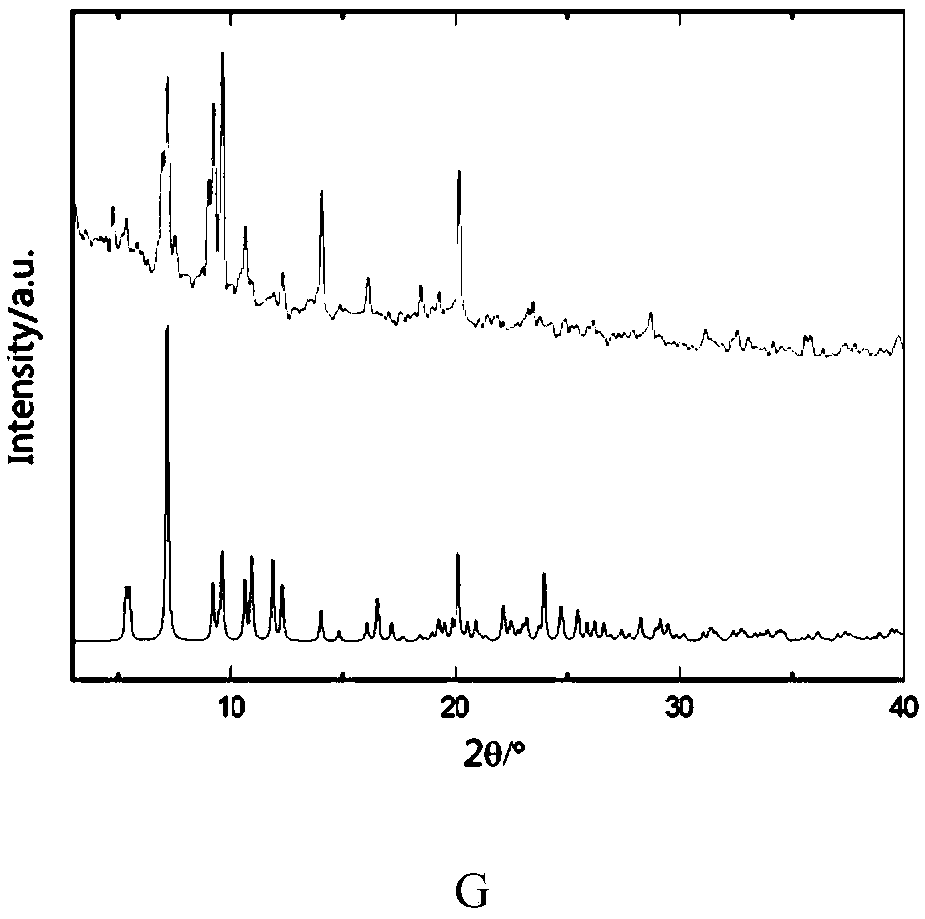

[0085] Embodiment 3 LMOF-3-Eu synthesis method

[0086] LMOF-3-Eu synthesis method: 0.1 g of ligand H3TATB, 0.1 g of europium nitrate hexahydrate were added to a glass vial containing 3 ml of N,N dimethylacetamide and 3 ml of dimethyl sulfoxide solvent, and 0.3 ml water, sonicated for fifteen minutes, placed in a 90-degree Celsius oven, and reacted for three days to obtain material No. 3, with a yield of 0.019 grams and a yield of 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com