A Method for Rapid Design of Trenchless Horizontal Directional Drilling Rig

A horizontal directional drilling machine, trenchless technology, applied in computing, special data processing applications, instruments, etc., can solve the constraints of urban construction progress of non-excavation production enterprises, undisclosed and reliable HDD rapid design technology methods, market changes Slow response and other issues, to achieve good application prospects, shorten the development cycle, reduce the effect of development and design costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

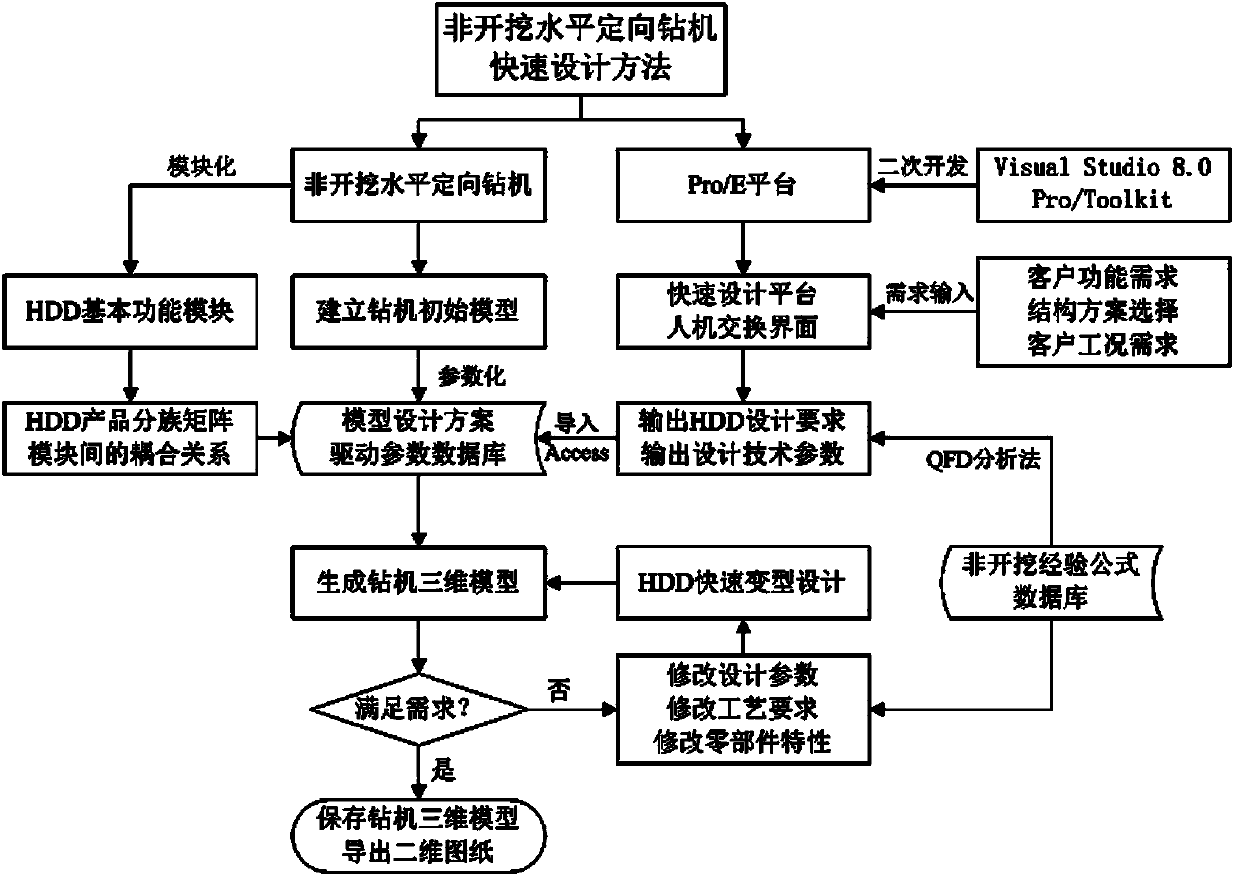

[0019] Example 1, such as figure 1 As shown, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0020] see figure 1 As shown in the present invention, a method for rapid design of a trenchless horizontal directional drilling machine, in the design process, firstly, according to the coupling relationship between the product family design idea and the internal parameters of the functional modules, the horizontal directional drilling machine is divided into functional modules , establish the product grouping matrix of the key components of the drilling rig; then use Pro / E software to parametrically model the functional modules, establish the initial model of the drilling rig with more than 8 schemes, and establish the driving parameter database; After the secondary development of the Pro / E software, the man-machine exchange interface is established; after the man-machine exchange interface after the se...

Embodiment 2

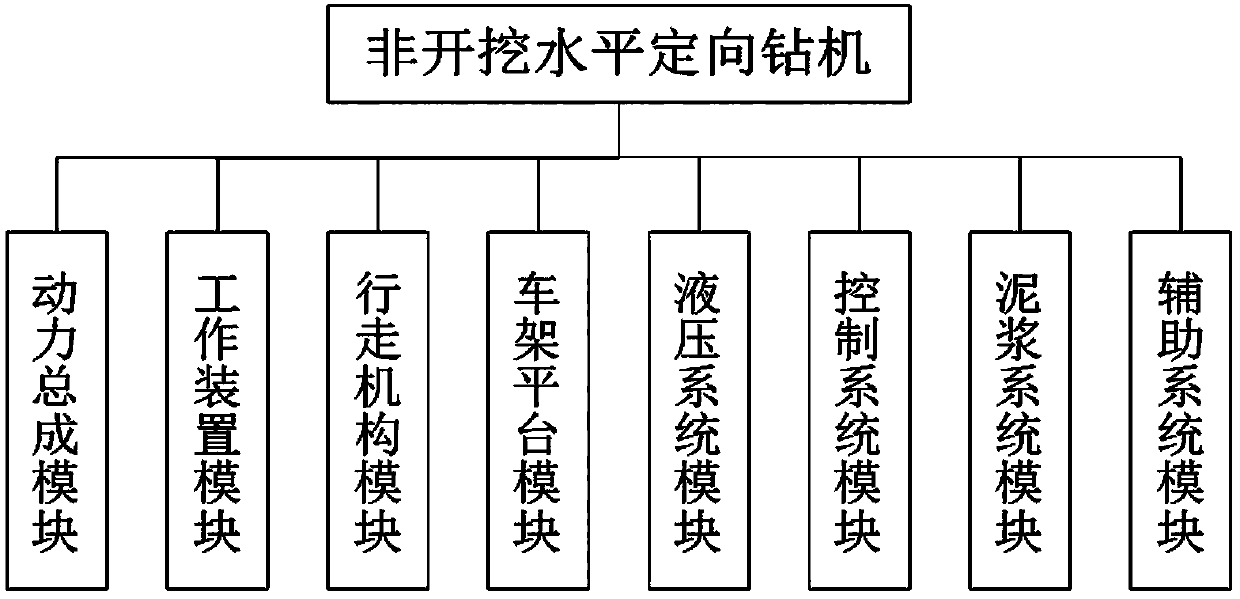

[0021] Example 2, see figure 2 As shown, the functional module division of the non-excavation horizontal directional drilling machine includes eight basic modules of power assembly, working device, traveling mechanism, frame platform, hydraulic system, control system, mud system and auxiliary system. According to the coupling relationship within each functional module, each basic module is divided into more than three sub-modules for further design. The working device includes the rotary module of the power head, the jacking and dragging module, the clamping vise module, the drill pipe, the drill bit and other non-excavation operation modules, and the auxiliary system includes the automatic loading and unloading module of the drill pipe and the truck-mounted crane module. , anchoring module, advanced cab and other auxiliary modules that can be increased or decreased according to customer needs. refer to Figure 1 to Figure 7 , all the other are with embodiment 1.

[0022] ...

Embodiment 3

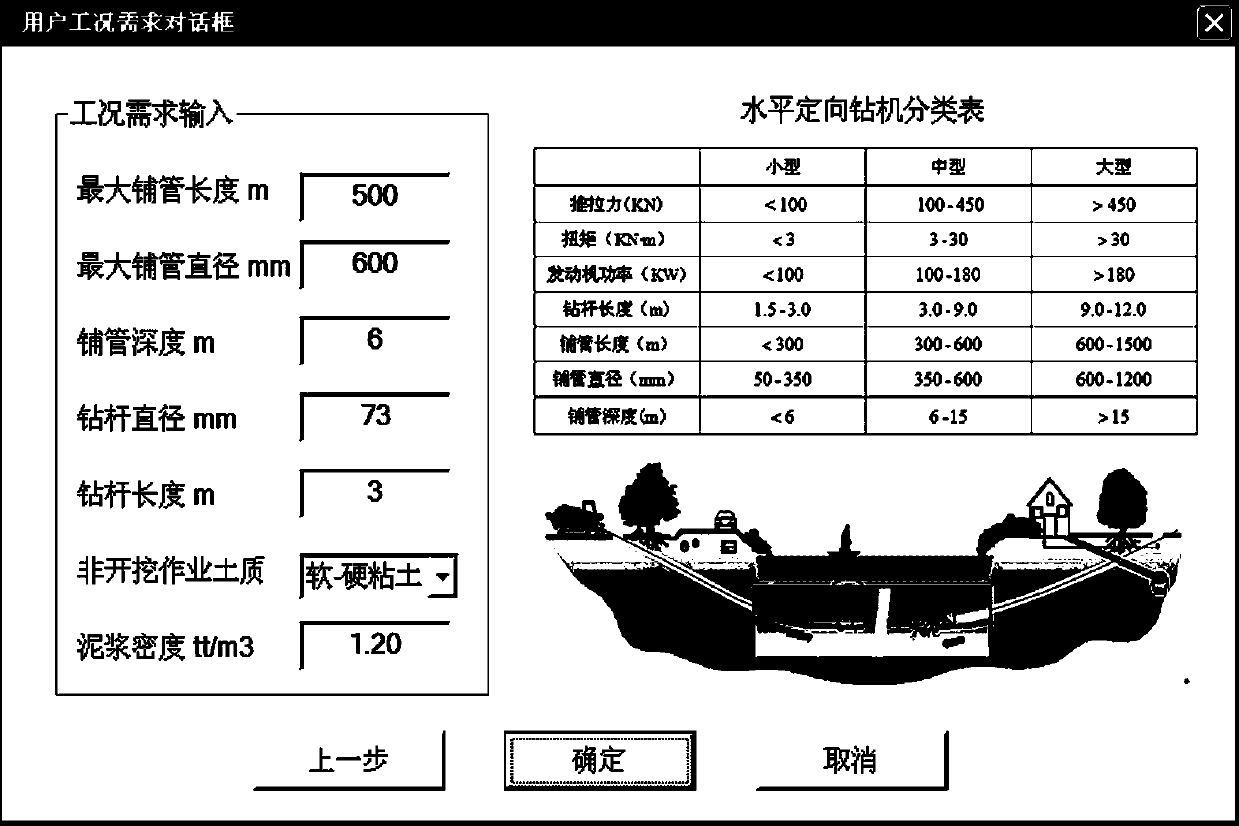

[0025] Embodiment 3, see image 3 As shown, in the HDD rapid design method, the input of the third part of the working condition requirements of the non-excavation customer demand input includes: maximum pipe laying length, maximum pipe laying diameter, pipe laying depth, drill pipe length and diameter, working soil quality, and mud density Such as non-excavation operation conditions demand input. After the system platform receives the data input of customer functional requirements, structural scheme selection, and working condition requirements, it analyzes and preprocesses the data, and then calculates HDD design technical parameters according to the preset trenchless empirical formula in the system program, and outputs and saves them. refer to Figure 1 to Figure 7 . All the other are with above-mentioned embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com