Progressive switchover heat storage type combustion device

A kind of combustion equipment and regenerative technology, which is applied in the field of progressive switching regenerative combustion equipment, can solve the problems of detonation and blasting furnace fuel, waste, large fluctuations in furnace pressure, etc., achieve full combustion, ensure smooth smoke exhaust, and furnace The effect of pressure stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Embodiments of the present invention will be described in detail below in conjunction with examples, but those skilled in the art will understand that the following examples are only used to illustrate the present invention, and should not be considered as limiting the scope of the present invention. Those who do not indicate the specific conditions in the examples are carried out according to the conventional conditions or the conditions suggested by the manufacturer.

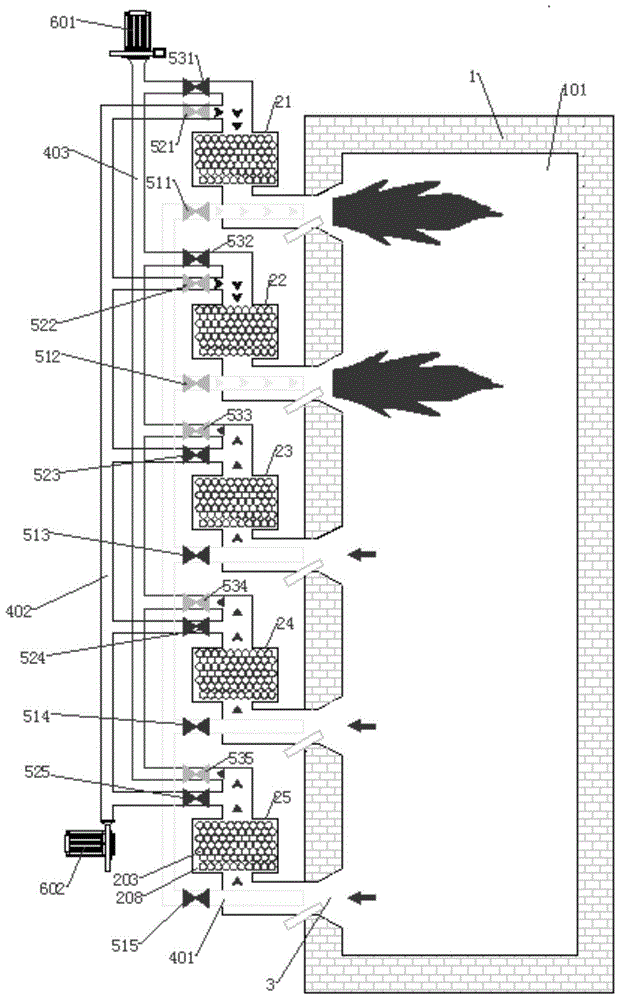

[0072] As a preferred embodiment of the present invention, such as figure 2 shown. A progressive switching regenerative combustion equipment in this embodiment includes a furnace body 1, a furnace 101 disposed in the furnace body 1, five regenerative burners 2, a gas pipeline 401, a combustion-supporting gas pipeline 402, The flue gas pipeline 403 and the reversing valve 5.

[0073] The furnace body 1 is not provided with an auxiliary pipe communicating with the furnace 101 for directly discharging t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com