Heating and ventilation control valve with automatic monitoring function

An automatic monitoring and control valve technology, applied in the field of mechanical parts, can solve the problems of high manufacturing and use costs, complex automatic monitoring structure, and power consumption, etc., and achieve the effects of low cost, wide-scale promotion and use, and real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

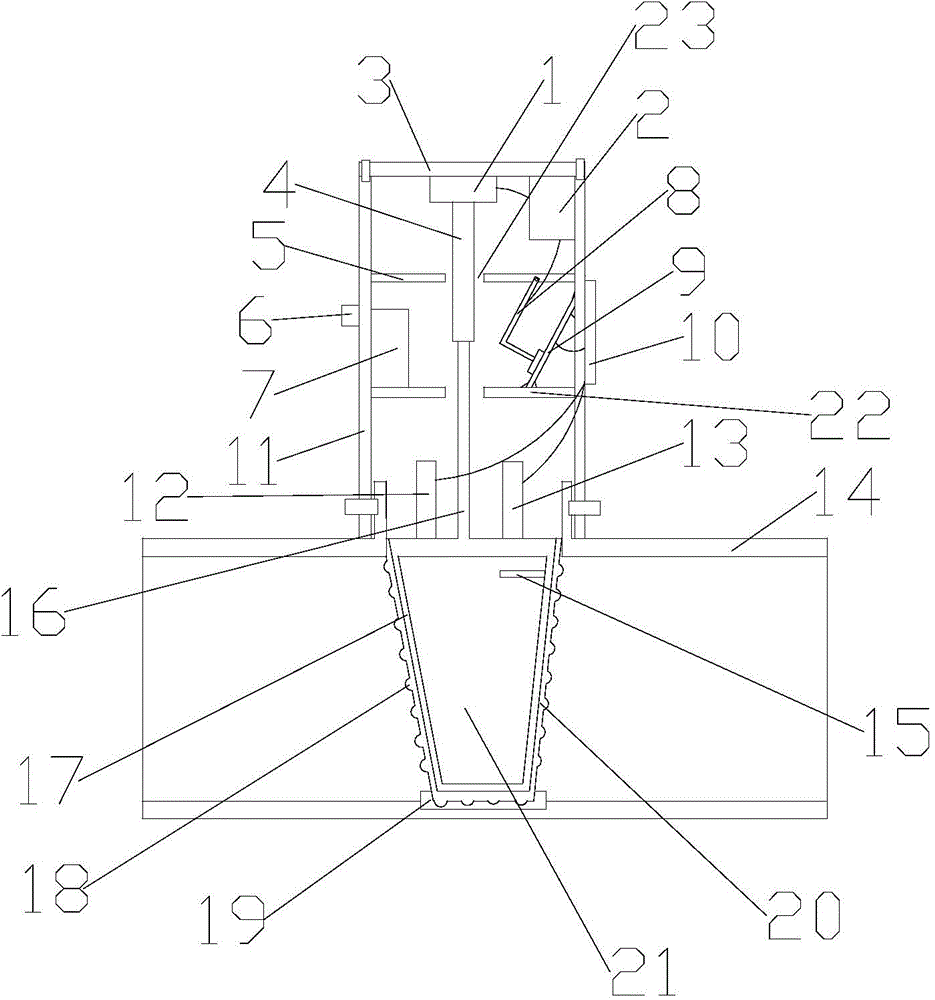

[0010] The following is attached figure 1 The present invention is further described:

[0011] In the figure: 1-cylinder, 2-motor, 3-cover, 4-piston, 5-first pallet, 6-timer, 7-flow monitor, 8-carbon brush, 9-control circuit board, 10 -display screen, 11-cover body, 12-temperature sensor, 13-humidity sensor, 14-valve body, 15-flow detector, 16-valve stem, 17-spool, 18-anti-skid protrusion, 19-valve seat , 20-rubber bushing, 21-inverted trapezoidal cavity, 22-second supporting plate, 23-through groove.

[0012] The present invention comprises a valve body 14, a valve seat 19 is arranged on the bottom of the valve body 14, a valve core 17 is arranged on the top of the valve seat 19, an inverted trapezoidal cavity 21 is arranged inside the valve core 17, and the outer surface of the valve core 17 is covered with rubber Bushing 20, the outer surface of the rubber bushing 20 is provided with anti-slip protrusions 18, the upper surface of the valve body 14 is provided with a cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com