Special-shaped spinneret plate and method for producing square-section colored FDY through special-shaped spinneret plate

A spinneret and special-shaped technology, applied to the production method and device field of square-section colored polyester yarn FDY, which can solve the problems of low packing density and improved wind-shielding performance, and achieve compact cross-section stacking, good solidification and formation, and enhanced flashing bright effect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

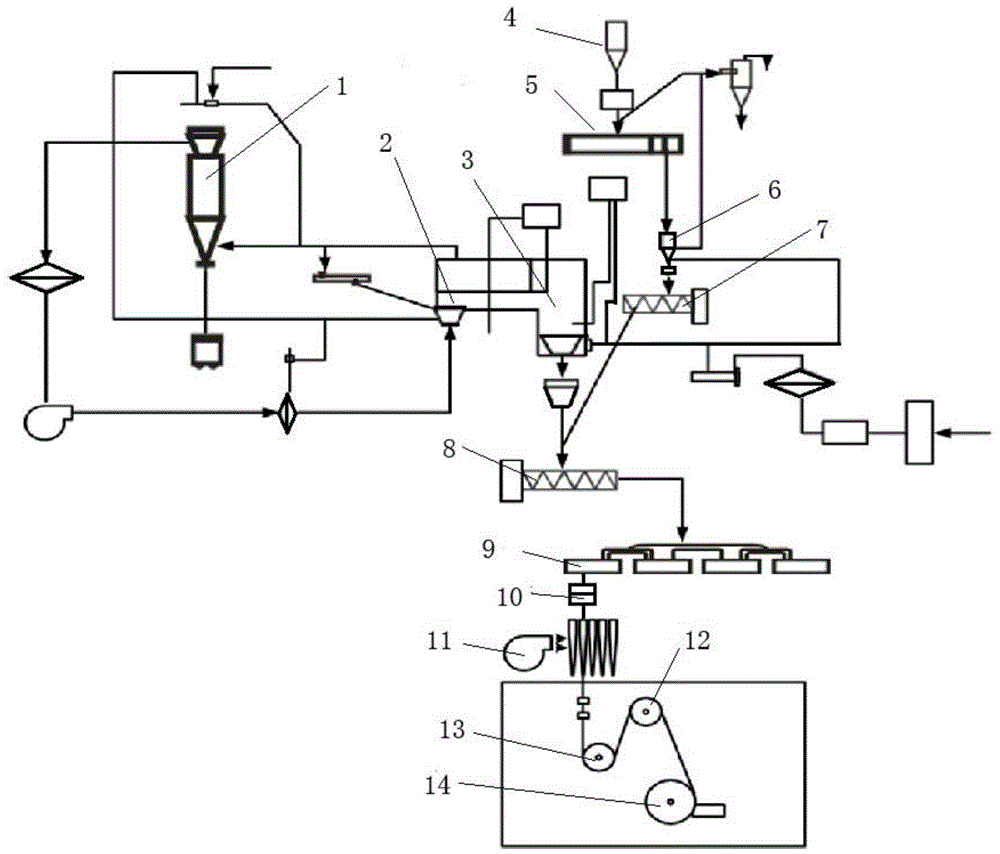

[0030] like figure 1 The production flow diagram of the square section colored polyester filament FDY shown.

[0031] Concrete described method comprises the following steps:

[0032] In step a, the slices in the slice silo 1 are sent to the pre-crystallizer 2 for pre-crystallization, then sent to the slice drying tower 3 for drying, and then sent to the screw extruder 8 for extrusion, heating, and melting to form a melt.

[0033] The polyester chip raw materials are vibrated and screened to remove powder and particles with inconsistent particle sizes, and the obtained chip raw materials are transported to the chip bin 1 for standby. Before melting, the chips are first sent to the pre-crystallizer 2 for pre-crystallization. Then it is sent to the slice drying tower 3 for drying to remove the moisture in the slice. The dried chips enter the screw extruder 8 for ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com