Rotational molding toilet room

A technology of rotational molding and corners, which is applied in the direction of building types, building materials processing, special buildings, etc., and can solve problems such as cumbersome and time-consuming installation and splicing, water leakage, and rain leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Example: see attached Figure 1-4 Shown:

[0020] A rotationally molded toilet house, comprising a top wall 1, a bottom wall 2, a front side wall 3, a rear side wall 4, a left side wall 5 and a right side wall 6, a toilet 21 is installed on the inner side of the bottom wall 2, and the front side wall 3 is provided with toilet room door 31. The toilet 21 can be a toilet or a squatting toilet.

[0021] See attached Figure 1-4 As shown, the top wall 1, the bottom wall 2, the front side wall 3, the rear side wall 4, the left side wall 5 and the right side wall 6 are integrally connected by rotational molding without seams, eliminating the problems of rain leakage and water leakage. Hidden danger.

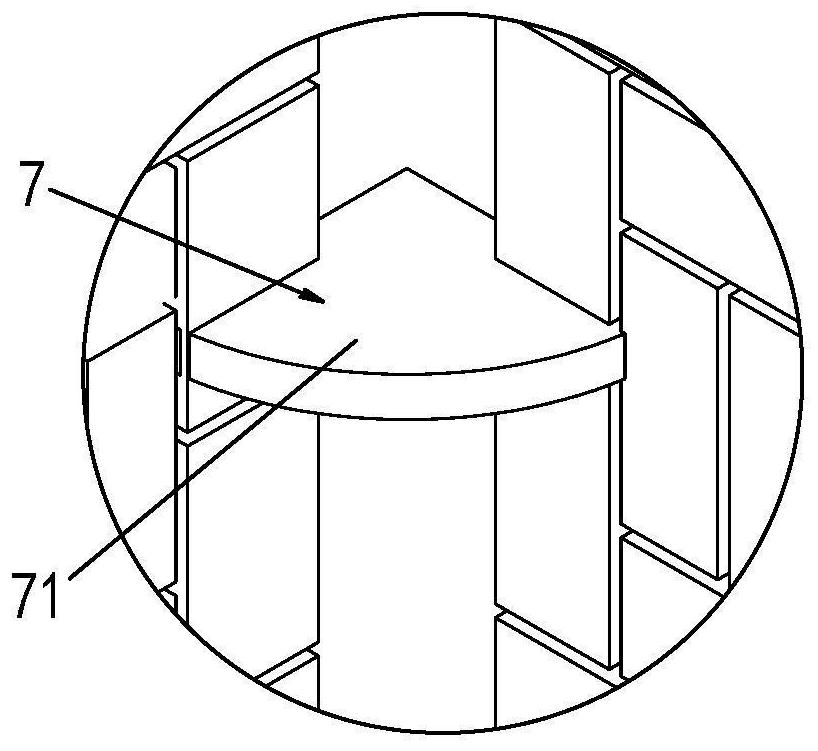

[0022] See attached Figure 1-4 As shown, especially among the four vertical corners of the toilet house, at least one group of diagonal corners is provided with a corner platform structure 7, and the example in the figure is that each of the four tight corners is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com