Transversely cutting device of paper cutter with double flying knives and method for adjusting length and squareness of cut paper

A technology of cross-cutting device and double rotation, which is applied in metal processing and other directions to achieve high working speed and improve the effect of adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

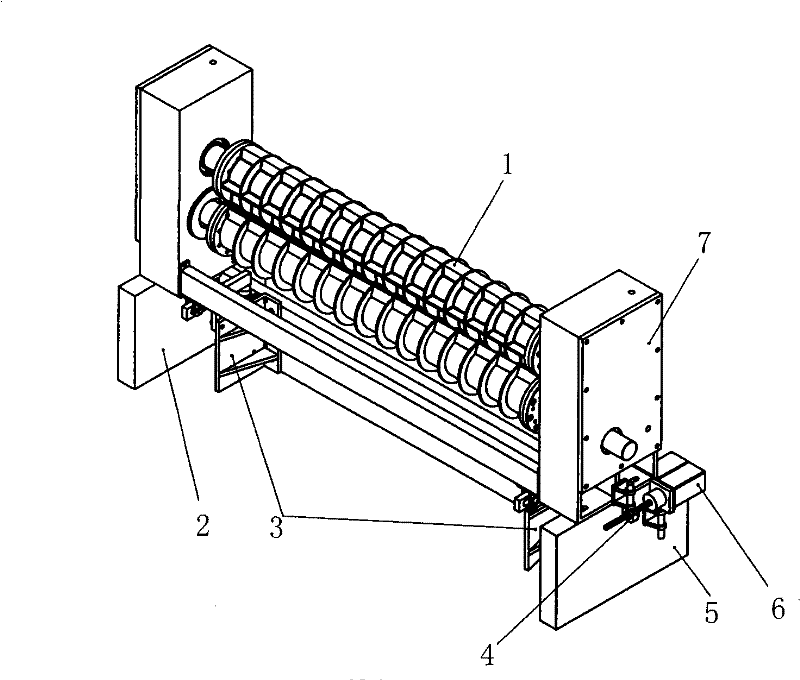

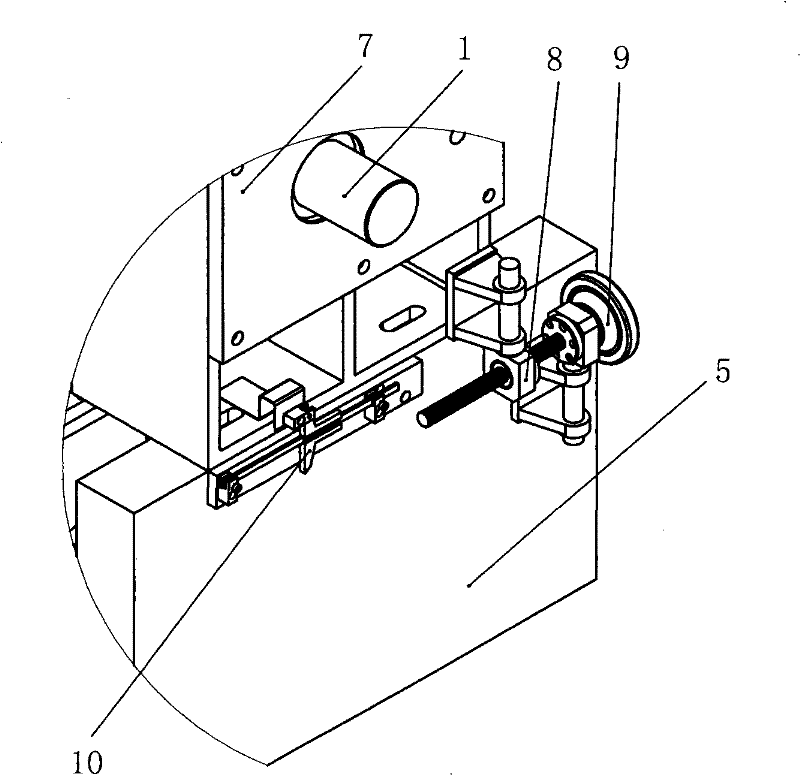

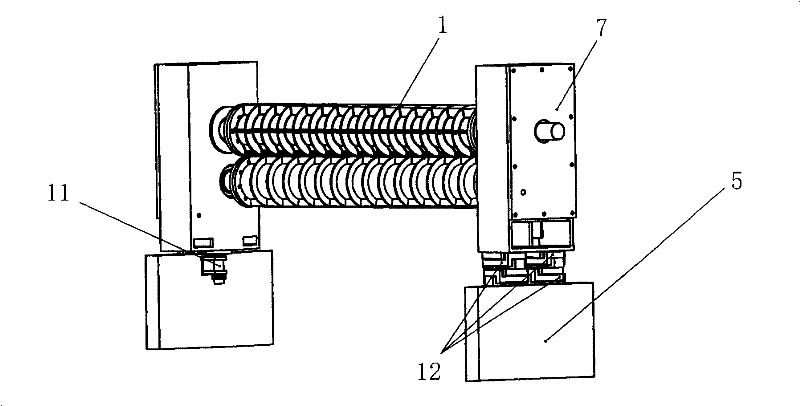

[0030] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

[0031] The working principle analysis of the cross-cutting device of the double-rotating knife paper cutter of the present invention:

[0032] (1) The upper and lower cylindrical rotary knife rollers are used to make a large angle Archimedes spiral knife groove on the outer surface of the cylindrical knife roller to install the blade to ensure that the knife edge is straight.

[0033] (2) The upper and lower cylindrical rotatable knife rolls are engaged with a gapless meshing device or a meshing device with a small gap with sufficient precision to ensure the correct position of the blades for each rotation of the two knives.

[0034] (3) The double-rotation cross-cutting knife roller runs at a constant speed when cutting paper of any specification. When adjusting the cutting length specifications, adjust the ratio of the knife roller to the running speed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com