Iron-making method by utilizing flash iron-making furnace

An ironmaking furnace and flash technology, applied in the field of metallurgy, can solve the problems of long process, large investment and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

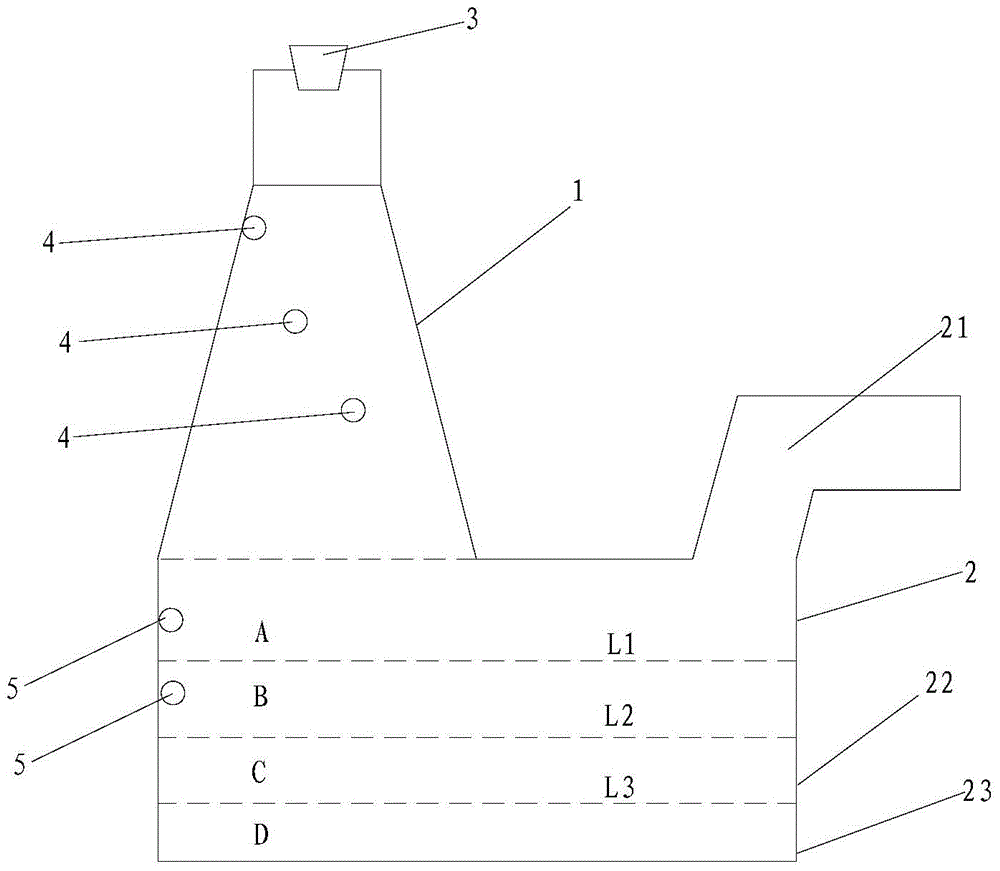

[0050] Provide iron ore concentrate raw materials with a particle size of 0.074 microns accounting for about 80%. use figure 1 The chamber blast furnace ironmaking plant shown performs ironmaking. First, the temperature in the cavity of the furnace body is controlled to be 1180-1220 degrees Celsius, and the reducing atmosphere contains 70-80 volume percent of carbon monoxide. Continuously dry iron concentrate, solvent and fuel including coke, pulverized coal and oxygen are sprayed into the cavity of the cavity furnace shaft 1 of the chamber blast furnace ironmaking device, and a high-temperature reduction system is formed in the reduction tower cavity. Reactive atmosphere; make dry iron concentrate and reducing gas undergo redox reaction in cavity furnace shaft 1 to obtain molten iron, slag and flue gas, and form coke layer, slag layer and molten iron from top to bottom in the molten pool layer. Continue to inject pulverized coal and oxygen into the slag layer of the molten...

Embodiment 2

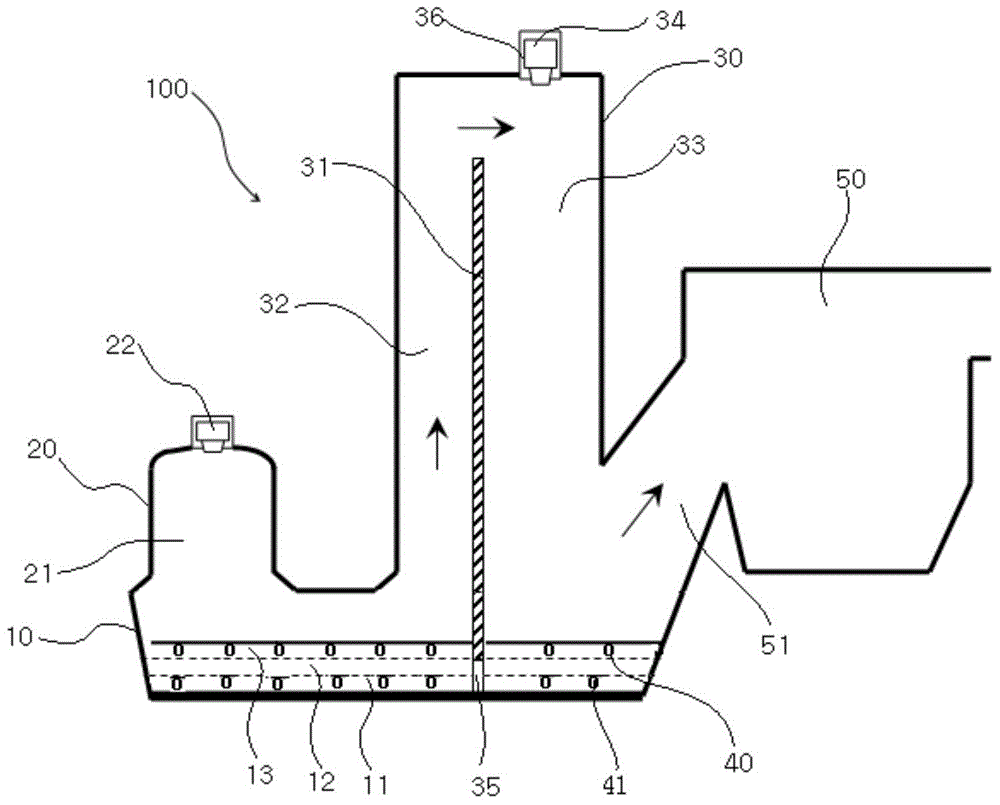

[0053] Provide iron ore concentrate raw materials with a particle size of 0.074 microns accounting for about 80%. use figure 1 The twin-tower flash furnace shown is used for iron smelting. First, the temperature in the cavity of the furnace body is controlled to be 1180-1220 degrees Celsius, and the reducing atmosphere contains 70-80 volume percent of carbon monoxide. Spray into the first reduction tower 20 continuous dry iron concentrate, solvent and fuel including coke, pulverized coal and oxygen, and make the first reduction tower 20 continue to form a high-temperature reducing atmosphere; make the dry iron concentrate and reduction The gas undergoes redox reaction in the first reduction tower 20 to obtain molten iron, slag and flue gas, and forms a coke layer, slag layer and molten iron layer from top to bottom in the molten pool.

[0054] The wet concentrate fed into the second reduction tower 30 is dried and pre-reduced by using the flue gas generated in the first redu...

Embodiment 3

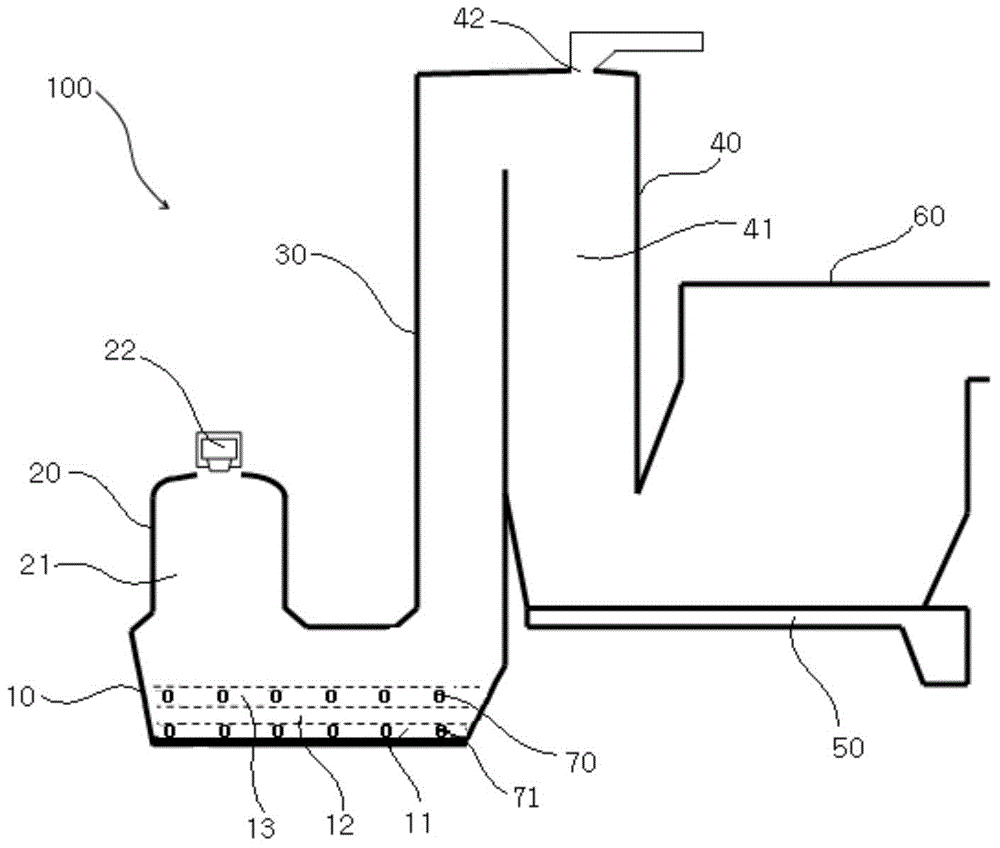

[0057] Provide iron ore concentrate raw materials with a particle size of 0.074 microns accounting for about 80%. use figure 1 The shown drying and reduction integrated flash ironmaking equipment is used for ironmaking. Firstly, the temperature inside the reduction tower body 20 is controlled to be 1180-1220 degrees Celsius, and the reducing atmosphere contains 70-80 volume percent carbon monoxide. Spray into the reduction tower body 20 continuous dry iron concentrate, solvent and fuel including coke, pulverized coal and oxygen, and make the reduction tower body 20 continue to form a high-temperature reducing atmosphere; make the dry iron concentrate and reducing gas in the Oxidation and reduction reactions occur in the reduction tower body 20 to obtain molten iron, slag and flue gas, and a coke layer, slag layer and molten iron layer are formed from top to bottom in the molten pool.

[0058] The wet concentrate fed into the pre-reduction drying tower 40 is dried and pre-red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com