Preparation method of petroleum degrading bacteria solid inoculant and method for restoring petroleum-polluted soil by using prepared solid inoculant

A technology of petroleum-degrading bacteria and solid bacterial agent, which is applied in the field of microbial remediation of petroleum-contaminated soil, and can solve problems such as unguaranteed actual effects, unrealized industrialized production, suboptimal viability, and unsatisfactory degradation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

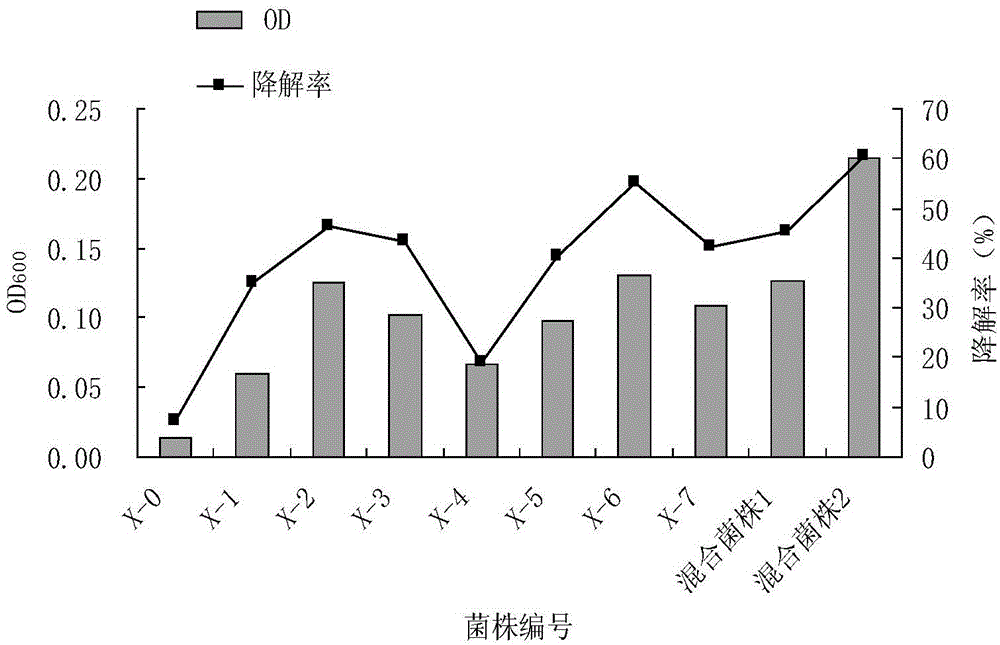

[0068] Screening of Efficient Petroleum Degrading Bacteria Strains

[0069] 1. Collection of oil-degrading indigenous bacteria sources

[0070] The oil-contaminated soil near the oil storage tank of the Shengli Oilfield refinery in Shandong Province was used as the source of indigenous oil-degrading bacteria. Sampling method: Use a small shovel to take soil samples with a thickness of 10cm, mix them evenly after sampling at multiple points, take 3kg soil samples and bring them back to the laboratory for later use.

[0071] 2. Preparation of Petroleum Polysorbate-80 Enhanced Solution

[0072]After the surfactant reaches the critical micelle concentration (CMC) in the aqueous solution, the solubility of some water-insoluble or slightly soluble substances in the micellar solution can be significantly increased to form a transparent colloidal solution. This effect is called solubilization. (solubilization). Polysorbate-80 (polyoxyethylene sorbitan fatty acid ester) is a water-s...

Embodiment 2

[0120] Liquid fermentation production of petroleum degrading bacterial agent

[0121] 1. Primary seed cultivation

[0122] Under sterile conditions, the mixed strain 2 of petroleum-degrading bacteria purified in Example 1 was inoculated in the slant culture medium of the test tube. Culture medium composition Per 1000ml sterile water: petroleum polysorbate-80 enrichment solution containing petroleum 0.125g equivalent (wherein petroleum mass concentration is 2%, polysorbate-80 mass concentration is 4%, remainder is water.), beef Cream 3g, peptone 10g, NaCl 5g, agar powder 20g, pH value is 7, sterilized at 121°C for 20 minutes. The culture conditions are: 30°C, cultured for 24 hours, and used as first-class seeds.

[0123] 2. Secondary seed cultivation

[0124] Under sterile conditions, take the two-ring primary seeds and put them into a 500ml Erlenmeyer flask filled with 200ml medium. Shake flask medium composition per 1000ml sterile water: petroleum polysorbate-80 enrichmen...

Embodiment 3

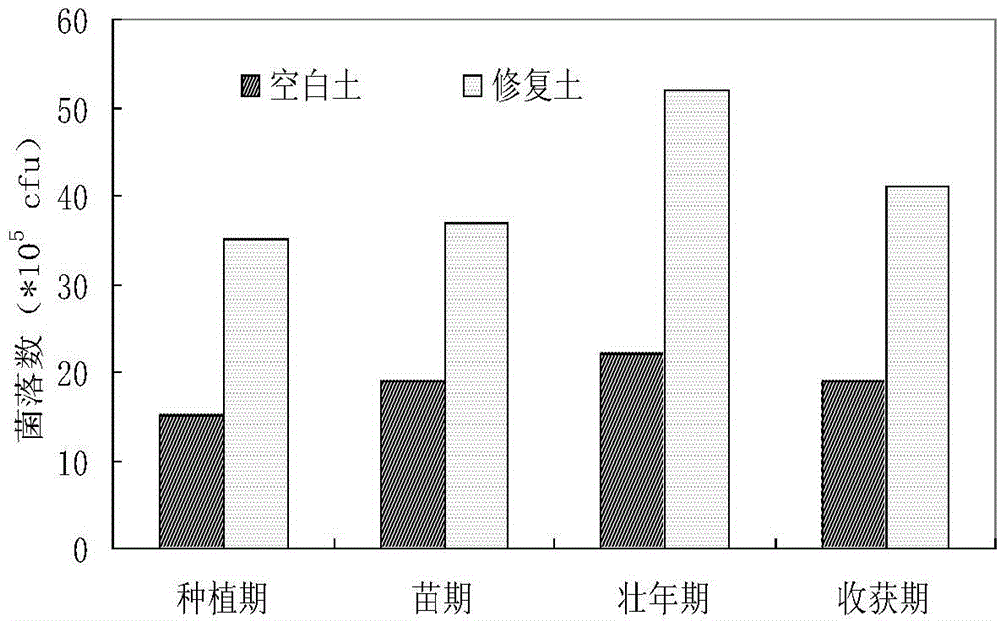

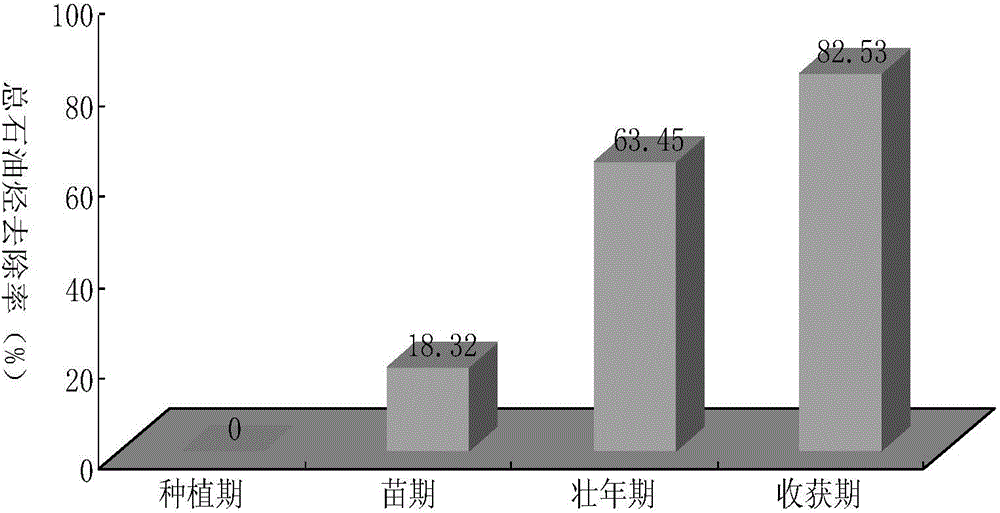

[0132] Combination of oil-degrading solid compound bacterial agent and plants to remediate oil-contaminated soil

[0133] 1. Selection and processing of experimental bases

[0134] This test selects the land near the oil extraction machine of an oil production plant in Dongying City. The land is located near the oil extraction machine and is polluted by oil. The total hydrocarbon content of oil is 4g / Kg. The basic physical and chemical properties of the soil are shown in Table 5. In the present invention, alfalfa-microbes are used to jointly restore oil-contaminated soil, and the planting density is about 8000 plants / mu. The prepared oil-degrading bacteria solid bacterial agent is added to the oil-contaminated soil at a rate of 10-100 kg / mu, and plowed. 0-30cm topsoil and mix well. When alfalfa is planted, the soil is covered with a film to retain moisture, and a controlled-release fertilizer is applied to ensure the nutrients needed for normal plant growth. At the seedling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com