Descaling agent for brine transportation pipeline, as well as usage method thereof

A descaling agent and pipeline technology, which is applied in the field of descaling agent and descaling agent to remove the scale layer of the brine pipeline, can solve the problems of large chemical reaction damage to the pipeline, and achieve high descaling efficiency, stable protection pressure, and construction. short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

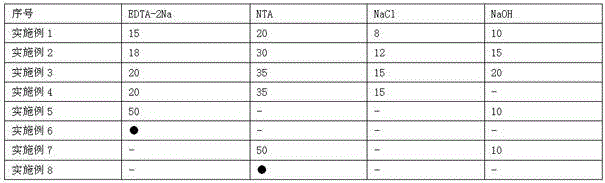

Examples

Embodiment Construction

[0016] In order to understand the purpose, technical solutions and beneficial effects of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following embodiments.

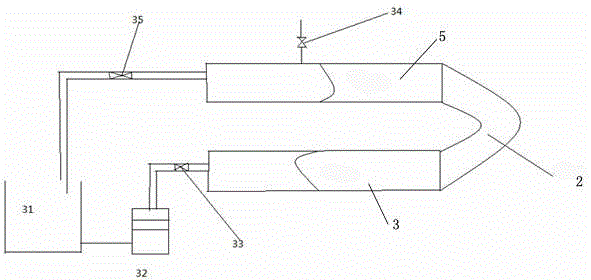

[0017] The descaling and cleaning process of the brine pipeline adopts a circulation process, which is divided into single-pipe circulation and double-pipe circulation. It can keep the descaling liquid in the state of flowing in the brine pipeline to be cleaned, and improve the scale dissolution effect of the mixed solution.

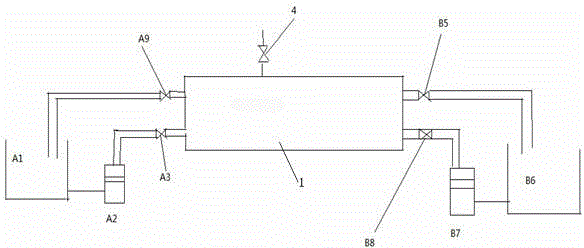

[0018] Such as figure 1 As shown, the descaling process of the single-pipe circulation of the brine pipeline is as follows: set the liquid storage tanks A1 and B6 at the two ends (A and B ends) of the brine pipeline 1 to be cleaned, and inject clean water into the liquid storage tank A1. According to the formula Add descaling agent and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com