Emulsion breaker for oil-water separation by efficiently treating crude oil with high clay component content on offshore oil field

An offshore oil field, oil-water separation technology, applied in the treatment of hydrocarbon oil, chemical dehydration/demulsification, petroleum industry, etc., can solve problems such as overloading of processing units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

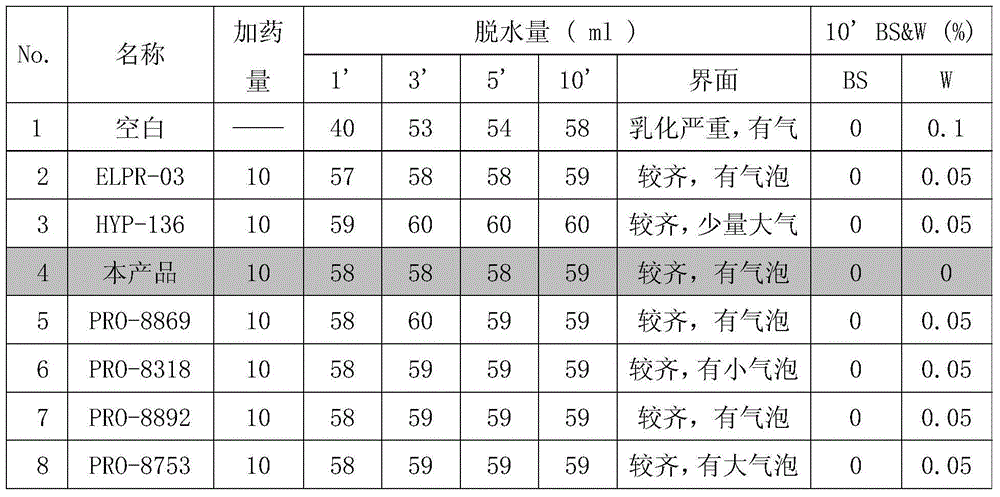

[0022] A kind of demulsifier for efficient treatment of oil-water separation of crude oil with high clay content in offshore oilfields, characterized in that: the weight percentage of each component of the demulsifier is composed of ethylenediamine polyoxypropylene polyoxyethylene ether (industrial product) 40%, ten Sodium hexaalkylsulfonate (industrial product) 0.4%, quaternary ammonium salt cationic fluorocarbon surfactant (industrial product) 0.7%, methanol (industrial product) 18%, 6-chlorobenzotriazole-1,1, 3,3-Tetramethyluronium hexafluorophosphate (industrial product) 10%, the rest is water.

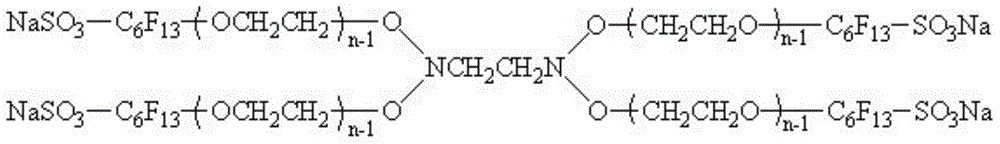

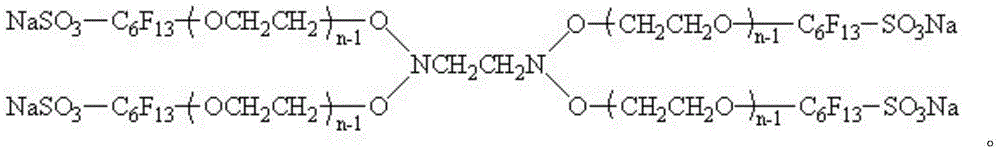

[0023] The demulsifier component ethylenediamine polyoxypropylene polyoxyethylene ether, sodium hexadecylsulfonate and quaternary ammonium salt cationic fluorocarbon surfactant are copolymerized into polyether fluorocarbon copolymer. The structural formula of ether fluorocarbon copolymer is

[0024]

Embodiment 2

[0026] Application of a demulsifier for efficient oil-water separation of crude oil with high clay content in offshore oilfields.

[0027] The preparation method of the demulsifier for efficient oil-water separation of crude oil with high clay content in offshore oilfields in Example 1: according to the formula, it is made by cross-linking and copolymerization in a high-pressure reactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com