Preparation method of chiral optical thin film with porphyrin intercalation DNA and hydrotalcite compound

A technology of optical thin film and hydrotalcite, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems that limit the application of LDH, and achieve the effects of signal amplification, high-density and orderly stacking, and high orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

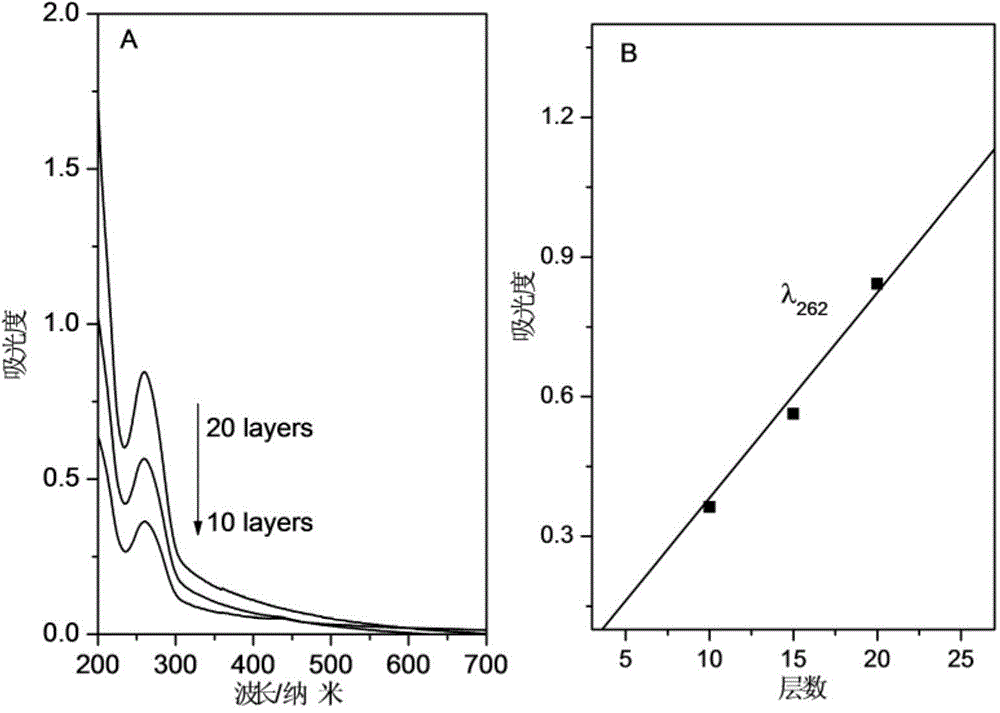

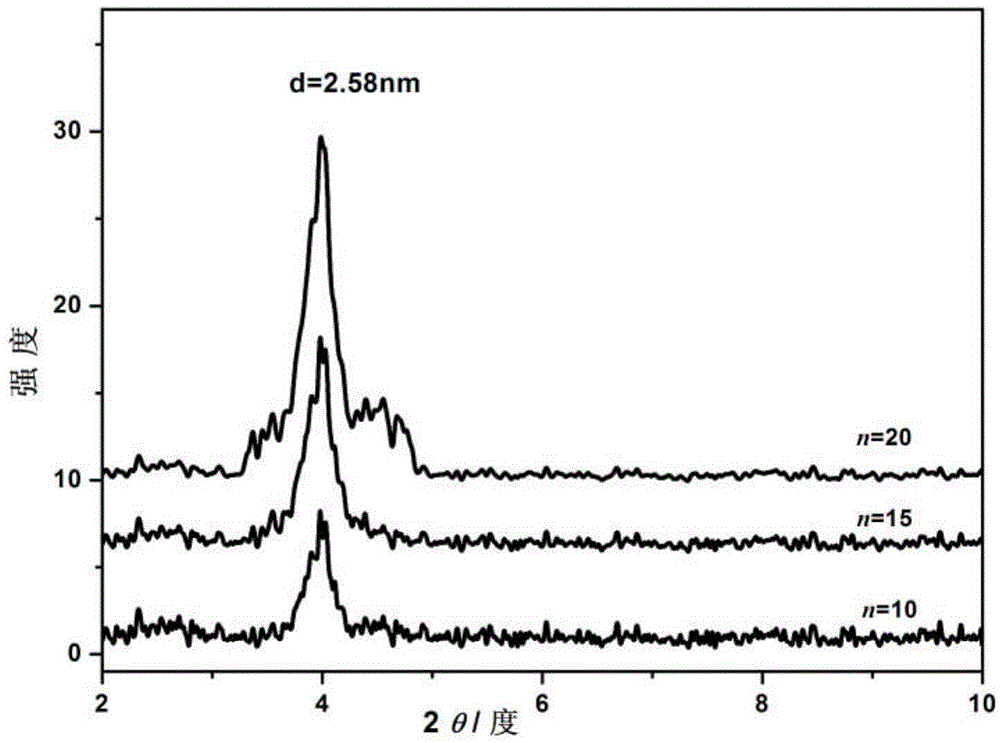

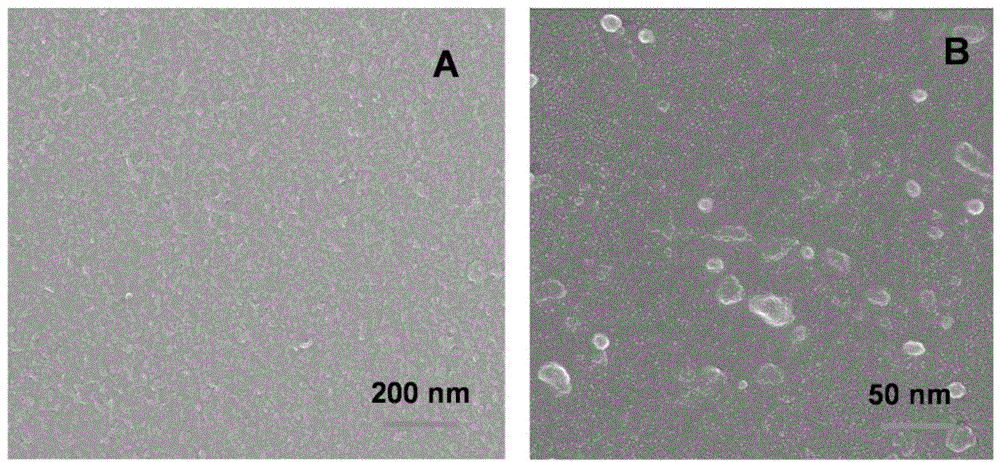

Method used

Image

Examples

Embodiment 1

[0025] Step A: take by weighing 15.38g Mg(NO 3 ) 2 ·6H 2 O and 11.25g Al(NO 3 ) 3 9H 2 O (Mg / Al=2) dissolved in 150ml to remove CO 2 , Deionized water to prepare mixed salt solution. Another 45ml NH 3 ·H 2 O adjust the above mixed salt solution to pH 8.5 to obtain a slurry. The slurry was placed in a pressure vessel and reacted at 140°C for 12h. use CO 2 1. Centrifugal washing with deionized water for 4 times to obtain a slurry, oven-dried at 60° C. for 24 hours, and the obtained powder product was sealed and stored.

[0026] Step B: Add 0.01 g of the powder product prepared in step A into a three-necked flask filled with 10 mL of formamide solvent, 2 Protected and stirred for 24h. After taking it out, it is centrifuged to remove solid impurities to obtain a clear and transparent colloidal solution, which is sealed and stored.

[0027] Step C: The quartz glass substrate is treated with H at a concentration of 30 wt%. 2 o 2 and concentrated H 2 SO 4 Soak in the...

Embodiment 2

[0035] Step A: take by weighing 23.04g Mg(NO 3 ) 2 ·6H 2 O and 11.25g Al(NO 3 ) 3 9H 2 O, Mg / Al=3, dissolved in 150ml to remove CO 2 , deionized water to prepare mixed salt solution, another 45ml NH 3 ·H 2 O adjust the above mixed salt solution to pH 8 to obtain a slurry. The slurry was placed in a pressure bomb and reacted at 130°C for 10h. use CO 2 1. Centrifugal washing with deionized water for 4 times to obtain a slurry, drying in an oven at 80° C. for 20 hours, and the obtained powder product is sealed and stored.

[0036] Step B: Add 0.05 g of the powder product prepared in step A into a three-necked flask filled with 50 mL of formamide solvent, 2 Protected and stirred for 20h. After taking it out, it is centrifuged to remove solid impurities to obtain a clear and transparent colloidal solution, which is sealed and stored.

[0037] Step C: The quartz glass substrate is treated with 30% H 2 o 2 and concentrated H 2 SO 4 The mixture (volume ratio 1:2) was s...

Embodiment 3

[0045] Step A: take by weighing 17.64g Zn(NO 3 ) 2 ·6H 2 O and 11.25g Al(NO 3 ) 3 9H 2 O, Zn / Al=2, dissolved in 150ml to remove CO 2 , deionized water to prepare mixed salt solution, another 45ml NH 3 ·H 2 O adjust the above mixed solution to pH 7 to obtain a slurry; place the slurry in a pressure vessel and react at 120°C for 10 h to remove CO 2 1. Centrifugal washing with deionized water for 3 times to obtain a slurry, oven-dried at 70° C. for 18 hours, and the obtained powder product was sealed and stored.

[0046] Step B: Add 0.2 g of the powder product prepared in step A into a three-necked flask filled with 150 mL of formamide solvent, 2 Protected and stirred for 15h. After taking it out, it is centrifuged to remove solid impurities to obtain a clear and transparent colloidal solution, which is sealed and stored.

[0047] Step C: The quartz glass substrate is treated with 30% H 2 o 2 and concentrated H 2 SO 4 The mixture (1:2) was soaked for 25min, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com