High-temperature-resistant polymer thickening agent for oil field fracturing fluid as well as preparation method and application of thickening agent

A high temperature-resistant polymer, oil field fracturing technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of unsuitable fracturing, etc., and achieve strong sand-carrying ability, good elasticity, and cross-linked jelly. good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

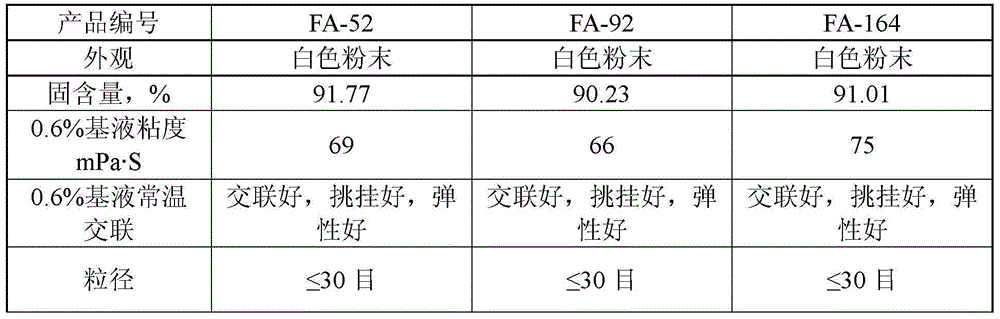

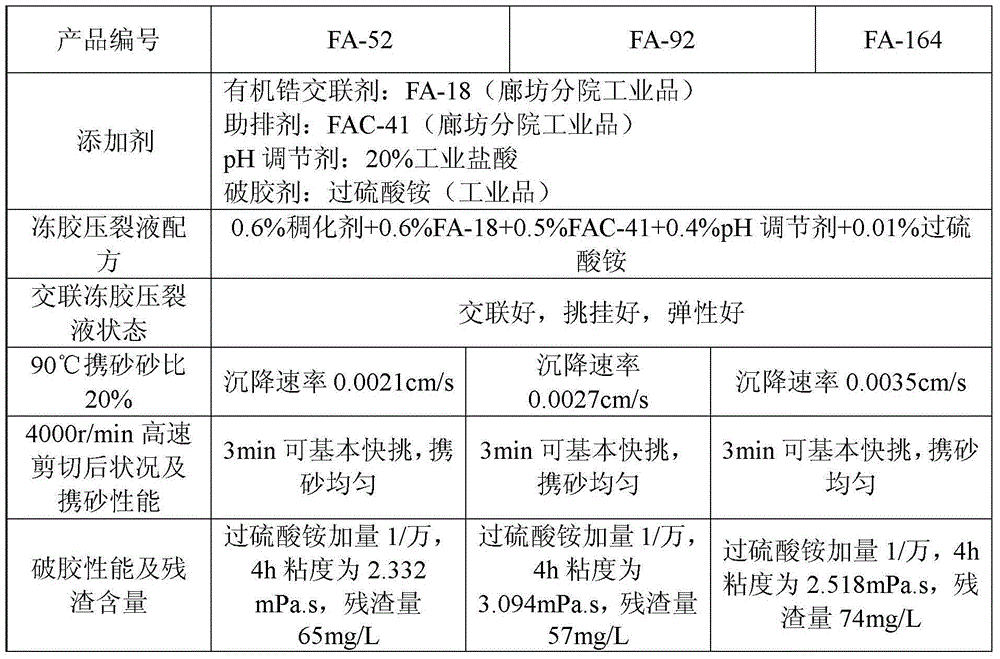

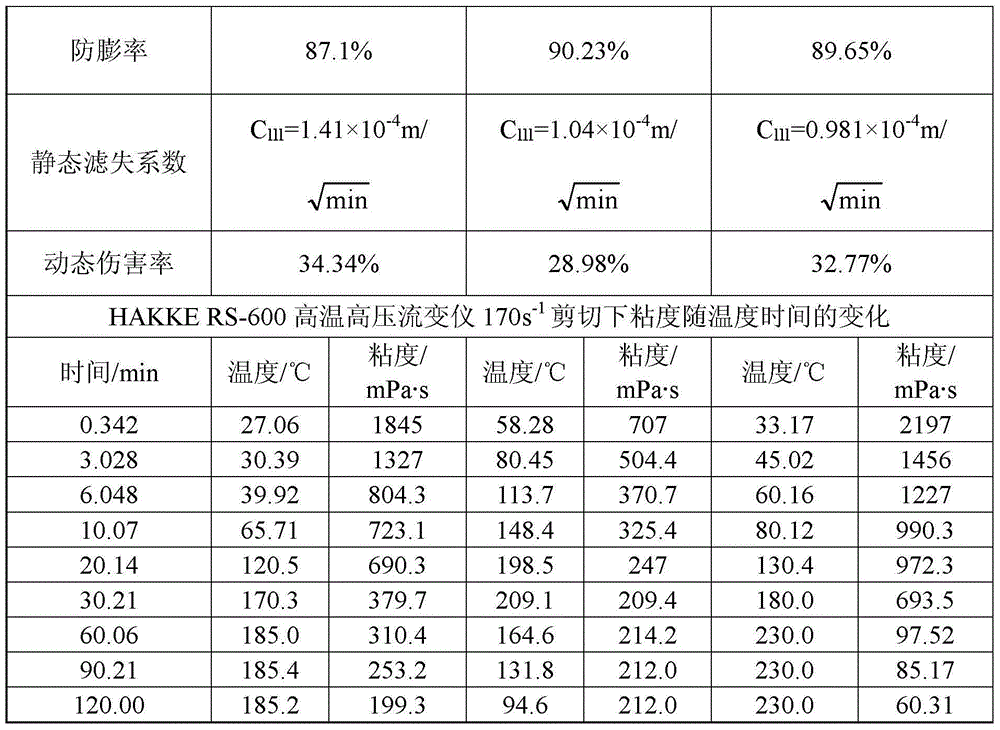

Examples

Embodiment 1

[0031] In this embodiment, AM (acrylamide), AMPS (2-acrylamido-2-methylpropanesulfonic acid), and NVP (N-vinylpyrrolidone) are used for polymerization.

[0032] The weight percent of each monomer component, initiator, chain transfer agent and water: AM: AMPS: NVP: potassium persulfate: sodium formate: H 2 O=15%: 10%: 5%: 0.09%: 0.06%: 69.85%.

[0033] Solution preparation: add 279.4g of deionized water to a 1000ml beaker, first add 7.72g of sodium hydroxide (solid) to it (sodium hydroxide is added mainly to make AMPS have better solubility), completely dissolve Afterwards, add AMPS 60g in the beaker again, slowly adjust pH with sodium hydroxide (40% liquid) and be about 4, then add AM 40g in the beaker successively, NVP 20g, and stir to dissolve completely, then add 0.24g of sodium formate.

[0034] Solution adjustment: add neutralizing agent sodium hydroxide (40% liquid) to the solution, adjust the pH of the solution to 6.3, and raise the temperature of the solution to 65° ...

Embodiment 2

[0038] In this embodiment, AM (acrylamide), MAA (methacrylic acid), and DMDAAC (methyl diallyl ammonium chloride) are used for polymerization.

[0039] The weight percent of each monomer component, initiator, chain transfer agent and water: AM: MAA: DMDAAC: ammonium persulfate: sodium bisulfite: sodium formate: H 2 O=17%: 8%: 5%: 0.02%: 0.06%: 0.06%: 69.88%.

[0040] Preparation of the solution: Add 279.52g of deionized water to a 1000ml beaker, first add 68g of AM to it, after it is completely dissolved, then add 32g of MAA to the beaker, after it is completely dissolved, add 20g of DMDAAC to it, And stir to dissolve completely, then add 0.24g of sodium formate to it.

[0041] Solution adjustment: add neutralizing agent sodium hydroxide (40% liquid) to the solution, adjust the pH of the solution to 6.8, and raise the temperature of the solution to 35° C.±2.

[0042] Polymerization of the solution: put the system in a water bath at 35°C, and blow nitrogen gas into the soluti...

Embodiment 3

[0045] In this embodiment, AM (acrylamide), AMPS (2-acrylamido-2-methylpropanesulfonic acid), DMC (methacryloyloxyethyltrimethylammonium chloride), DMAA (N, N- Dimethacrylamide) four monomers are polymerized.

[0046] The weight percent of each monomer component and water: AM: AMPS: DMC: DMAA: Ammonium persulfate: Sodium bisulfite: Sodium formate: H 2 O=15%: 5%: 5%: 5%: 0.03%: 0.03%: 0.1%: 69.84%.

[0047] Preparation of the solution: add 280g of deionized water to a 1000ml beaker, first add 3.86g of sodium hydroxide (solid) to it, after completely dissolving, then add 20g of AMPS to the beaker, and use sodium hydroxide (40% liquid) Slowly adjust the pH to about 4, then add AM 60g, DMC 20g, and DMAA 20g to the beaker in turn and stir to dissolve completely, then add 0.40g of sodium formate to it.

[0048] Solution adjustment: add neutralizing agent sodium hydroxide (40% liquid) to the solution, adjust the pH of the solution to 7, and cool the solution to 10° C.±1.

[0049] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com