High-strength moisture-proof starch glue and preparation method and application method thereof

An application method and technology of starch glue, applied in the directions of starch adhesives, chemical instruments and methods, polymer adhesive additives, etc., can solve the problem that related products cannot be used normally, starch glue and products are debonded, and starch glue is not water-resistant. and other problems, to achieve the effect of convenient application, good binding force and good moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

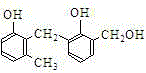

Method used

Image

Examples

Embodiment 1

[0059] A kind of high-strength moisture-proof starch glue of the present embodiment is made up of the following raw materials of weight part:

[0060] Cornstarch 100g

[0061] Phenolic oligomer 8g

[0062] Polylactic acid 2g

[0063] Borax 1g

[0064] Nickel sulfate hexahydrate 0.5g

[0066] Tributyl Phosphate 1g

[0067] 25g of water.

[0068]Add 80% of the total water to the starch and stir evenly, then add sodium peroxide and nickel sulfate during the stirring process, and when it becomes translucent, add borax. Before adding, borax should be dissolved in 20% of the total water, and the water temperature should be 80°C. After stirring evenly, add phenolic oligomer, polylactic acid and tributyl phosphate in turn, and let it stand for 0.5-1.5 hours to obtain high-strength Moisture-proof starch glue.

[0069] Spread the prepared starch glue on the corrugated medium paper to bond the surface paper and the core paper, then apply a pressure of ...

Embodiment 2

[0071] A kind of high-strength moisture-proof starch glue of the present embodiment is made up of the following raw materials of weight part:

[0072] Cornstarch 100g

[0073] Phenolic oligomer 15g

[0074] Polylactic acid 8g

[0075] Borax 2g

[0076] Nickel sulfate hexahydrate 1g

[0077] Sodium peroxide 10g

[0078] Tributyl Phosphate 2g

[0079] 250g of water.

[0080] Add 70% of the total water to the starch and stir evenly, then add sodium peroxide and nickel sulfate during the stirring process, and add borax when it becomes translucent. Before adding, borax is first dissolved in 30% of the total water, the water temperature is 60°C, after stirring evenly, add phenolic oligomer, polylactic acid and tributyl phosphate in turn, and let it stand for 0.5h to obtain high-strength moisture-proof starch glue.

[0081] Apply the prepared starch glue on the corrugated medium paper to bond the surface paper and the core paper, then apply a pressure of 0.4 MPa to it, and pl...

Embodiment 3

[0083] A kind of high-strength moisture-proof starch glue of the present embodiment is made up of the following raw materials of weight part:

[0084] Cornstarch 100g

[0085] Phenolic oligomer 10 g

[0086] Polylactic acid 5 g

[0087] Borax 0.8 g

[0088] Nickel sulfate hexahydrate 2 g

[0089] Sodium peroxide 3 g

[0090] Tributyl phosphate 3 g

[0091] 200 g of water.

[0092] Add 75% of the total water to the starch and stir evenly, then add sodium peroxide and nickel sulfate during the stirring process, and add borax when it becomes translucent. Before adding, borax was first dissolved in 25% of the total water in water at a temperature of 75°C. After stirring evenly, phenolic oligomers, polylactic acid and tributyl phosphate were added in sequence, and stood for 1 hour to obtain high-strength moisture-proof starch glue. .

[0093] Spread the prepared starch glue on the corrugated medium paper to bond the surface paper and the core paper, then apply a pressure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com