High-ultraviolet-reflectivity reflective insulation coating and preparation method thereof

A reflective thermal insulation coating, reflectivity technology, applied in reflective/signal coatings, antifouling/underwater coatings, coatings, etc., can solve the problem of shortening the service life of the coating, accelerating the aging of the coating, and changing the coating temperature. problems, to avoid accelerated aging, strong adhesion, good heat insulation and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Correspondingly, an embodiment of the present invention also provides a preparation method of the above-mentioned high ultraviolet reflectivity reflective heat-insulating coating. This preparation method comprises the steps:

[0040] Step S01: Obtain each component separately according to the composition and content of the high ultraviolet reflectance reflective heat-insulating coating of the present invention;

[0041] Step S02: Mixing the weighed components.

[0042] Specifically, in the above step S01, the components of the high ultraviolet reflectance reflective heat-insulating paint are as described above, and will not be repeated here to save space.

[0043] The mixing process in the above step S02 is to make the weighed components mix uniformly to form a stable coating system.

[0044] In order to improve the dispersibility of each component and improve the stability of the high-ultraviolet reflectance reflective heat-insulating coating, in one embodiment, when...

Embodiment 1

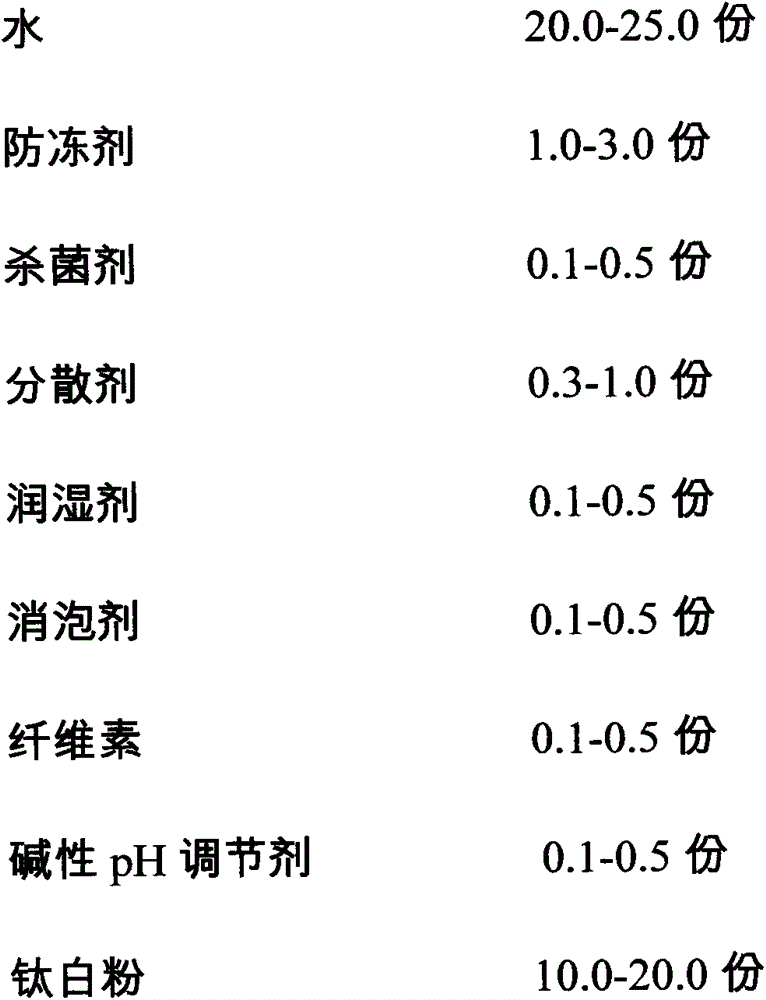

[0048] The invention discloses a high ultraviolet reflectivity reflective heat-insulating paint component formula and a preparation method thereof. The reflective heat-insulating coating with high ultraviolet reflectivity contains the following components by weight:

[0049]

[0050]

[0051] Its preparation method comprises the following steps:

[0052] S11. Obtain each component according to the composition and content of the high ultraviolet reflectance reflective heat insulation coating described above;

[0053] S12. Add the components weighed in step S11 into water in order according to the following order for mixing treatment, so that the components are mixed evenly: bactericide, wetting agent, dispersant, antifreeze agent, defoamer, cellulose , Alkaline pH adjuster, titanium dioxide, filler, UV reflective slurry, emulsion, film-forming aid, mildew-proof additive, thickener.

Embodiment 2

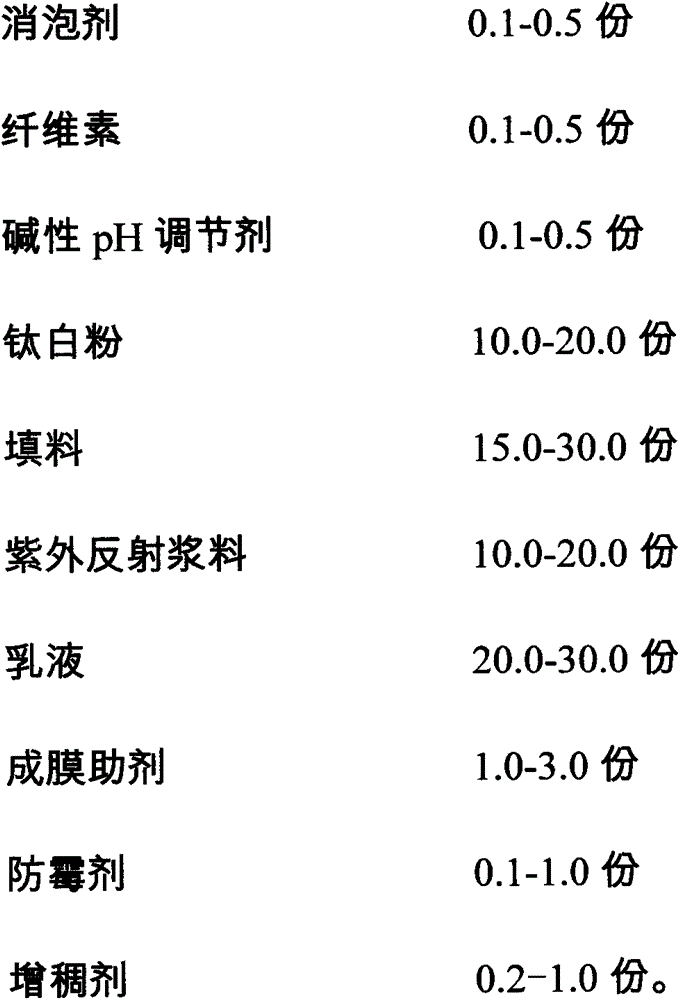

[0055] The invention discloses a high ultraviolet reflectivity reflective heat-insulating paint component formula and a preparation method thereof. The reflective heat-insulating coating with high ultraviolet reflectivity contains the following components by weight:

[0056]

[0057]

[0058] Its preparation method comprises the following steps:

[0059] S21. Obtain each component according to the composition and content of the high ultraviolet reflectance reflective heat-insulating coating;

[0060] S22. Add the components weighed in step S21 into water in the following order for mixing treatment, so that the components are mixed evenly: bactericide, wetting agent, dispersant, antifreeze agent, defoamer, cellulose , Alkaline pH adjuster, titanium dioxide, filler, UV reflective slurry, emulsion, film-forming aid, mildew-proof additive, thickener.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com