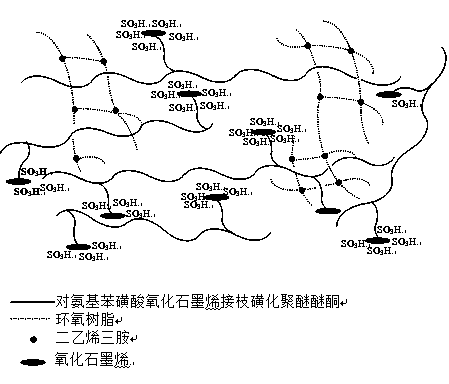

P-aminobenzene sulfonic acid graphene oxide grafted sulfonated polyetheretherketone proton exchange membrane material and preparation method thereof

A technology for sulfonating polyether ether ketone and p-aminobenzenesulfonic acid, which is applied in the field of p-aminobenzenesulfonic acid grafted sulfonated polyether ether ketone proton exchange membrane material and its preparation, can solve the problem of alcohol permeability coefficient and High water swelling rate, unusable for astronauts, polluting water generated by batteries, etc., to achieve low preparation cost, increase water swelling resistance, and avoid physical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

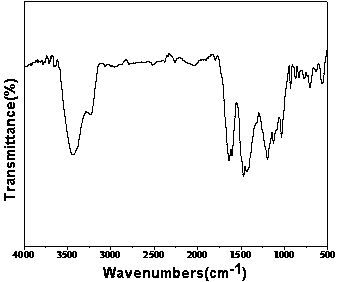

Method used

Image

Examples

Embodiment 1

[0028] (1) Dissolve (1.7000g, 0.0050mol) SPEEK (65% sulfonation degree) in 30 mL of DMAc solvent in a 100 mL three-neck flask equipped with magnetic rotor stirring, condenser, and thermometer, and turn on the magnetic force Stir, and heat the oil bath to 60°C to prepare a film-forming solution;

[0029] (2) Under nitrogen protection, add (0.1892g, 0.0050mol) NaBH at one time to the film-forming solution obtained in step (1) 4 , heated to 100°C for reflux reaction for 12 hours, centrifuged and purified to obtain the supernatant;

[0030] (3) Add graphene oxide (0.08825g) and coupling agent (3.10g, 1.5ml) into toluene (7g, 8ml), and stir mechanically for 12 hours at 100°C under inert gas protection.

[0031] (4) In a 500mL three-neck flask equipped with a magnetic rotor stirring, condenser, and HCl absorption device, put the solution of (3) in DMAc solvent, add the supernatant obtained in step (2) dropwise, and stir in an ice-water bath React for 24 hours.

[0032] (5) In a 5...

Embodiment 2

[0058] (1) Dissolve (3.4000g, 0.0100mol) SPEEK (sulfonation degree 75) in 30 mL of DMAc solvent in a 100 mL three-neck flask equipped with magnetic rotor stirring, condenser, and thermometer, and turn on the magnetic stirring , heat the oil bath to 100°C, and prepare a film-forming solution;

[0059] (2) Under the protection of nitrogen, add (0.3783g, 0.0100mol) NaBH4 to the membrane-forming solution obtained in step (1) at one time, raise the temperature to 90°C for reflux reaction for 18 hours, centrifuge and purify, and obtain the supernatant;

[0060] (3) Add graphene oxide (0.1765g) and coupling agent (6.20g, 0.31ml) into toluene (14g, 16ml), and stir mechanically for 12 hours at 100°C under inert gas protection.

[0061] (4) In a 500mL three-neck flask equipped with a magnetic rotor stirring, condenser, and HCl absorption device, put the solution of (3) in DMAc solvent, add the supernatant obtained in step (2) dropwise, and stir in an ice-water bath React for 24 hours. ...

Embodiment 3

[0073] (1) Dissolve (2.0400g, 0.0060mol) SPEEK (68% sulfonation degree) in 30 mL of DMAc solvent in a 100 mL three-neck flask equipped with magnetic rotor stirring, condenser, and thermometer, and turn on the magnetic stirring , heat the oil bath to 100°C, and prepare a film-forming solution;

[0074] (2) Under the protection of nitrogen, add (0.2270g, 0.0060mol) NaBH4 to the membrane-forming solution obtained in step (1) at one time, heat up to 120°C for reflux reaction for 10 hours, centrifuge and purify, and obtain the supernatant;

[0075] (3) Add graphene oxide (0.26475g) and coupling agent (9.3g, 9ml) into toluene (21g, 24ml), and stir mechanically for 12 hours at 100°C under inert gas protection.

[0076] (4) In a 500mL three-neck flask equipped with a magnetic rotor stirring, condenser, and HCl absorption device, put the solution of (3) in DMAc solvent, add the supernatant obtained in step (2) dropwise, and stir in an ice-water bath React for 24 hours.

[0077] (5) I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com