Method of preparing apigenin by treating adinandra nitida leaves by steam explosion technology

A technology for processing apigenin, which is applied in the field of preparing apigenin by the steam explosion method, can solve the problems of high waste water treatment cost, unfriendly environment, difficulty in adaptation, etc., achieve high production cost, expand the scope of use, and save production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

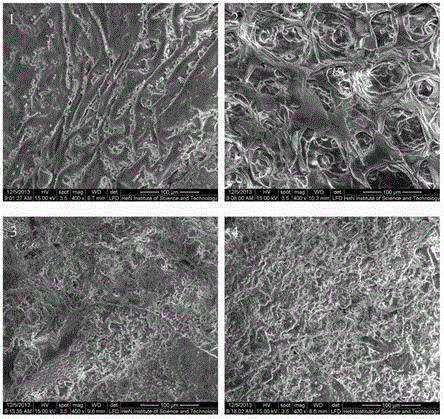

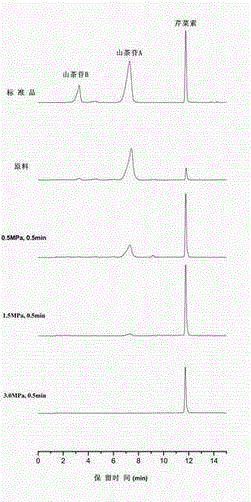

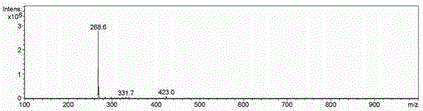

[0027] Take 100 g of poplar leaves and dry them at 65 °C until the dry matter content reaches 87.6%, put them into a steam explosion equipment, maintain a pressure of 0.5 MPa for 2 min, and then explode instantly to obtain poplar leaves in an explosive state, and dry them to The mass content of dry matter reaches 87.8%, and it is pulverized and sieved to 40 mesh to obtain the processed raw material. Put the above raw materials into a condensing reflux device, add 1000 mL of 70% ethanol solution, extract in a water bath at 60 °C for 3 h, and then filter with suction to obtain an apigenin extract. The extract was evaporated in vacuo at 60°C to remove ethanol, and the precipitate precipitated from the remaining solution was collected and dried to obtain crude apigenin. The obtained crude product was added to 1000 mL of ethanol, heated and dissolved in a water bath at 80 °C for 3 h, and then suction-filtered, and the filtrate was allowed to cool and recrystallized to obtain 8.53 g...

Embodiment 2

[0030] 100 g of poplar leaves were dried at 65 ℃ until the mass content of dry matter reached 87.7%, put into steam explosion equipment, maintained at a pressure of 1.0 MPa for 1.5 min, and then exploded instantly to obtain poplar leaves in an explosive state, which were dried to The dry matter mass content reaches 87.9%, and pulverizes and sieves 40 orders, obtains the raw material after processing. Put the above raw materials into a condensing reflux device, add 1500 mL of 60% ethanol solution, extract in a water bath at 80 °C for 2.5 h, and then filter with suction to obtain an apigenin extract. The extract was evaporated in vacuo at 50° C. to remove ethanol, and the precipitate precipitated in the remaining solution was collected and dried to obtain crude apigenin. The obtained crude product was added to 2000 mL of ethanol, dissolved at 80 °C for 2.5 h, then suction filtered, and the filtrate was allowed to cool and recrystallized to obtain 8.87 g of apigenin with a purity...

Embodiment 3

[0033] 100 g of poplar leaves were dried at 65 ℃ until the dry matter content reached 87.8%, put into steam explosion equipment, maintained at a pressure of 2.0 MPa for 1.0 min, and then exploded instantly to obtain poplar leaves in an explosive state, which were dried to The mass content of dry matter reaches 87.6%, and it is pulverized and sieved to 40 mesh to obtain the processed raw material. Put the above raw materials into a condensing reflux device, add 2500 mL of 50% ethanol solution, extract in a water bath at 70 °C for 2 h, and then filter with suction to obtain an apigenin extract. The extract was evaporated in vacuo at 40°C to remove ethanol, and the precipitate precipitated from the remaining solution was collected and dried to obtain crude apigenin. The obtained crude product was added to 2500 mL of ethanol, dissolved at 80 °C for 2 h, then suction filtered, and the filtrate was cooled and recrystallized to obtain 8.25 g of apigenin with a purity of 95.89%.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com