A kind of preparation method of naphthol as

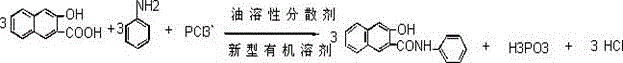

A chromophenol and process technology, applied in the preparation field of chromophenol AS, can solve the problems of poor dispersibility of the reaction system, incomplete reaction, long condensation time, etc., and achieve the effects of improving yield and quality, thorough reaction and good product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention is further illustrated below through specific examples.

[0022] Specific embodiments of the present invention: since the naphthol AS is condensed in an anhydrous state of an organic solvent, it is necessary to ensure that there is no water in the reaction system before it can be operated, that is, to ensure that chlorobenzene, amino, 2-hydroxyl-3- Naphthoic acid cannot be damp and wet, and aniline cannot be water-containing and discolored; wear labor protection supplies and conduct detailed inspections on equipment and other aspects, and follow-up operations can only be performed after confirming that there is no problem.

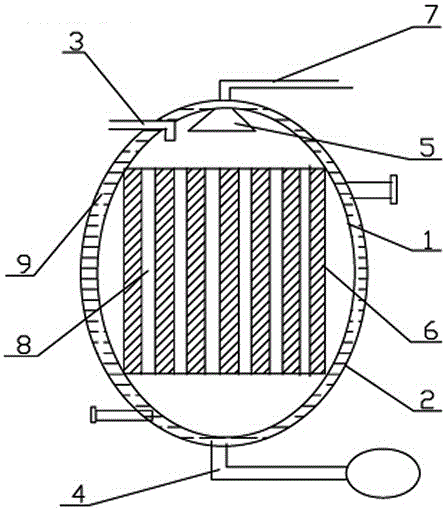

[0023] 1) First check that there is no water in the suspension pot, open the solvent feed valve and add 5000L of chlorobenzene and 2000L of o-chlorotoluene that has been screened;

[0024] 2) Turn on and stir to mix evenly, then add 1200kg of 2-hydroxy-3-naphthoic acid and 12kg of screened oil-soluble ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com