Preparation method of high-temperature-resistant antioxidant for improving fried food storage quality

A fried food and anti-oxidant technology, which is applied in the direction of food preservation, separation/purification of carboxylic acid compounds, and preservation of fatty substances with additives, etc., can solve the problems of limited production efficiency and high cost of extraction production and operation, and achieve low cost, Antioxidant effect is remarkable, the effect of high extraction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 200 g of dried rosemary leaves, crush them, add 1 L of n-hexane and chloroform mixed extract (n-hexane: chloroform = 2:1), and use low-frequency and low-power ultrasound for segmental leaching for 6 hours, that is, ultrasonication for 1 hour, Turn off the ultrasound, extract the solvent for 2 hours, and reciprocate for 2 cycles; the ultrasonic frequency is 20-30KHZ, the power is 150W, the temperature is 70°C, the extraction time is 6 hours, filter, collect the filter residue, repeat 3 times; collect the above organic Concentrate the solvent phase under reduced pressure, and evaporate to dryness in a rotary evaporator at 35°C to obtain paste A; dissolve the above paste A in 10 times the volume of acetone, stir for 30 minutes, filter, and dissolve the filter residue a second time , filtered, and the combined filtrate was concentrated under reduced pressure to obtain paste B; the paste B was dissolved in 10 times the volume of n-hexane, re-dissolved, stirred for 30 mi...

Embodiment 2

[0028]Weigh 200 g of dried rosemary leaves, crush them, add 1 L of n-hexane and chloroform mixed extract (n-hexane: chloroform = 2:1), and use low-frequency and low-power ultrasound for segmental leaching for 6 hours, that is, ultrasonication for 1 hour, Turn off the ultrasound, extract the solvent for 2 hours, and reciprocate for 2 cycles; the ultrasonic frequency is 20-30KHZ, the power is 300W, the temperature is 80°C, the extraction time is 6 hours, filter, collect the filter residue, and repeat 2 times; collect the above organic Concentrate the solvent phase under reduced pressure, and evaporate to dryness in a rotary evaporator at 35°C to obtain paste A; dissolve the above paste A in 10 times the volume of acetone, stir for 30 minutes, filter, and dissolve the filter residue a second time , filtered, and the combined filtrate was concentrated under reduced pressure to obtain paste B; the paste B was dissolved in 10 times the volume of n-hexane, re-dissolved, stirred for 30...

Embodiment 3

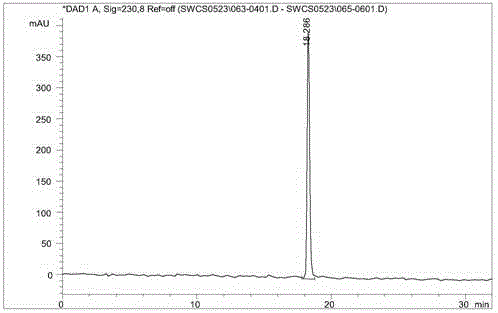

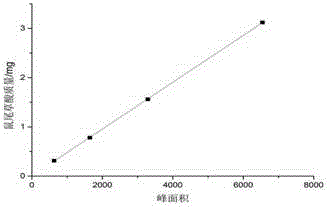

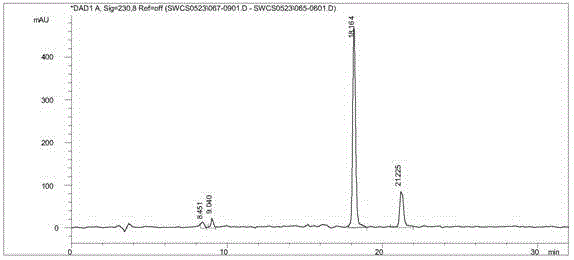

[0030] Verification of the prepared product: Carnosic acid in the crude extract was determined by high performance liquid chromatography (HPLC) external standard method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com