Adhesion agent as well as preparation method and application thereof

An adhesive and component technology, used in the field of building materials, can solve the problems of sticking the base layer and the harsh position, crack resistance, reduced waterproof performance, damage to the polymer molecular chain, etc., to achieve good construction performance, good resistance to sag and Anti-slip ability, simple and easy-to-operate preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

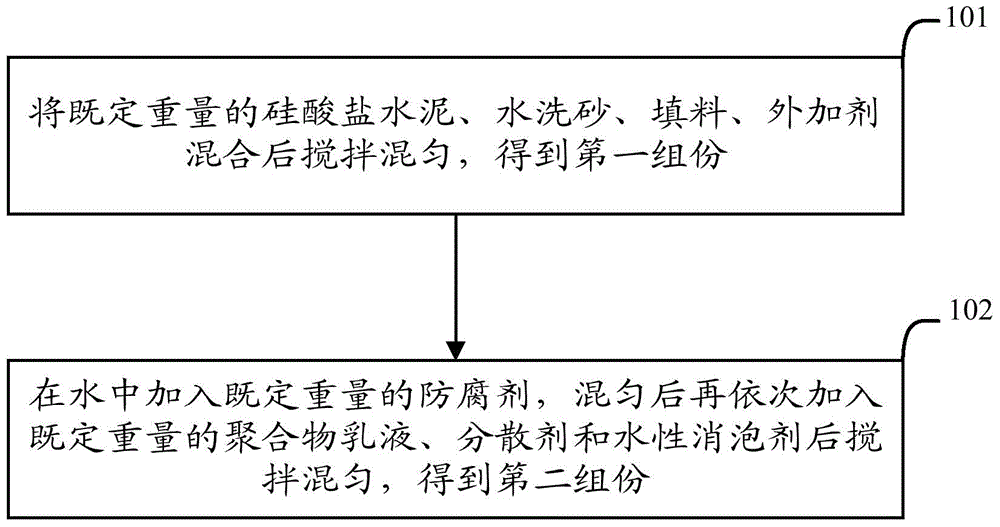

[0042] Please refer to figure 1 , the preparation method of the above-mentioned binder that the present invention also provides, comprises the following steps:

[0043] Step 101: Mix Portland cement, water-washed sand, fillers, and admixtures with a predetermined weight, and then stir and mix to obtain the first component.

[0044] In step 101, in order to make the various raw material components be mixed uniformly, the preferred stirring time is 8-12 minutes, and the stirring operation is completed in a blender.

[0045] Step 102: Add a predetermined weight of preservative into the water, mix well, then sequentially add predetermined weight of polymer emulsion, dispersant and water-based defoamer, stir and mix to obtain the second component.

[0046] In step 102, in order to make the preservative mix well with water, preferably, after it is added to water, stir for 2 minutes, then add polymer emulsion, dispersant (optional) and water-based defoamer in sequence, and low speed...

Embodiment 1

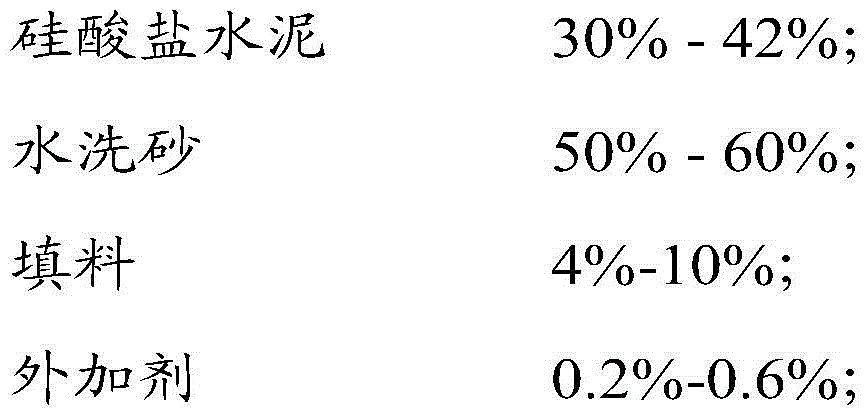

[0049] The binder provided by the embodiment of the present invention, in the first component, in terms of weight percentage, its raw materials include: Portland cement 30%; washed sand 60%; filler 9.4%; admixture 0.6%;

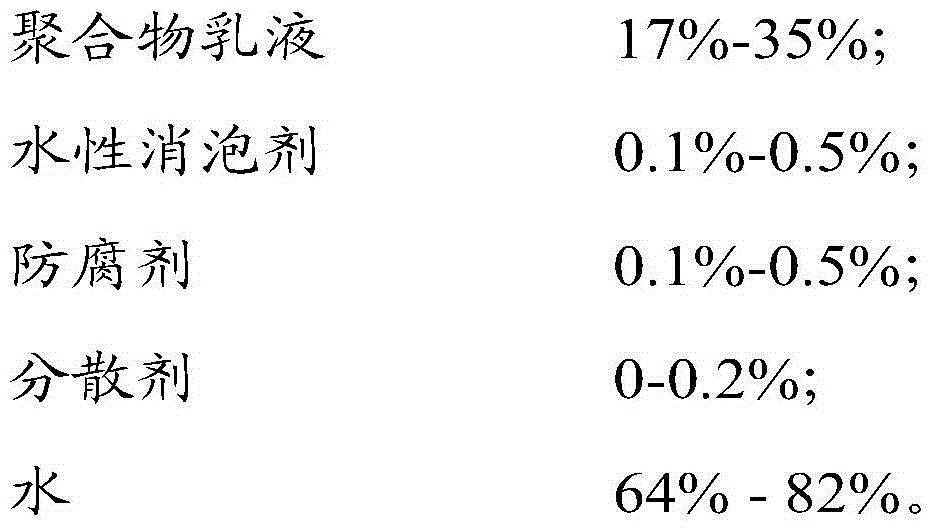

[0050] In the second component, according to weight percentage, its constituent materials include: 17% of acrylic emulsion; 0.5% of water-based defoamer; 0.5% of preservative; and 82% of water.

[0051] Among them, the washed sand is mixed sand with a particle size of 40-70 mesh and 70-140 mesh; the filler is heavy calcium powder and mineral powder with equal weight ratio; agent.

[0052] Preparation

[0053] S11: Mix Portland cement, washed sand, filler and admixture of a predetermined weight and stir for 8 minutes to obtain the first component;

[0054] S12: Add a predetermined weight of preservative into the water, stir for 2 minutes, then add predetermined weight of acrylic emulsion and water-based defoamer in turn, and stir for 28 minutes to obtain the...

Embodiment 2

[0056] The binder provided by the embodiment of the present invention, in the first component, in terms of weight percentage, its raw materials include: Portland cement 42%; washed sand 50%; filler 7.8%; admixture 0.2%;

[0057] In the second component, in terms of weight percentage, its constituent materials include: styrene-butadiene emulsion 35%; water-based defoamer 0.4%; preservative 0.4%; dispersant 0.2%; water 64%.

[0058] Among them, the washed sand is a mixed sand with a particle size of 40-70 mesh and 70-140 mesh; the filler is fly ash and stone powder in an equal weight ratio; the admixture is a water-retaining agent, an anti-slip agent and an early strength agent in an equal weight ratio .

[0059] Preparation

[0060] S21: Mix Portland cement, washed sand, fillers, and admixtures of a predetermined weight, and then stir for 10 minutes to obtain the first component;

[0061] S22: Add a predetermined weight of preservative into the water, stir for 2 minutes, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com