Process for treating ammonia-nitrogen wastewater with medium and low concentration through catalytic ozonation of metallic oxides

A low-concentration ammonia nitrogen and ozone oxidation technology, applied in special compound water treatment, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problem of no ammonia nitrogen, achieve no secondary pollution, high purification efficiency, simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

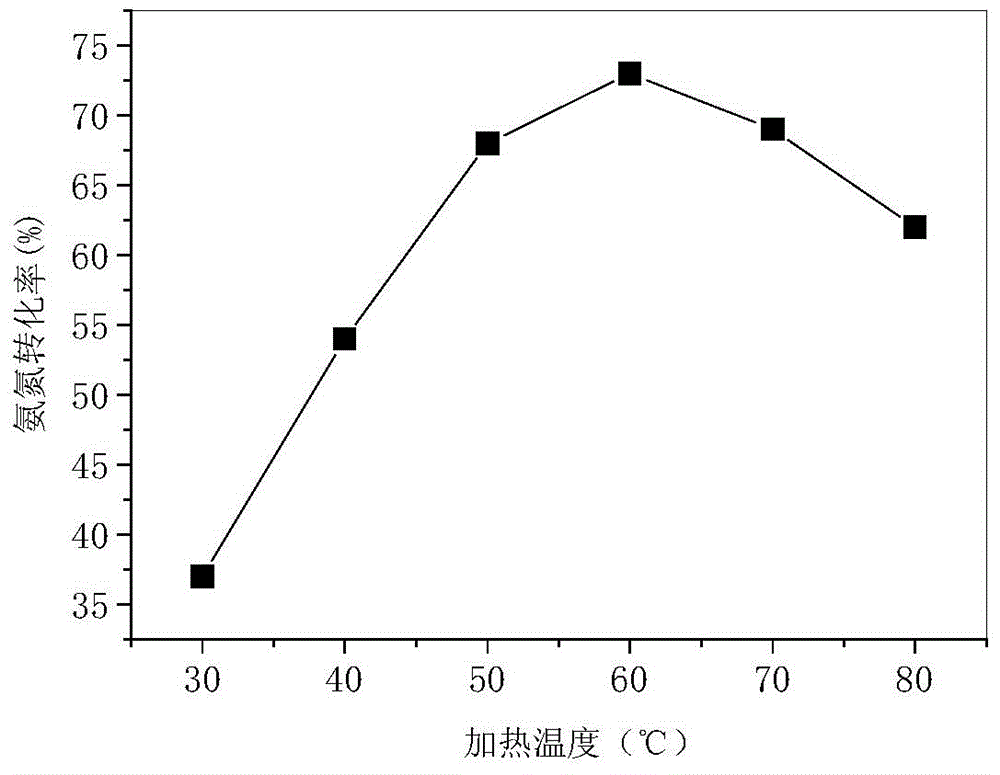

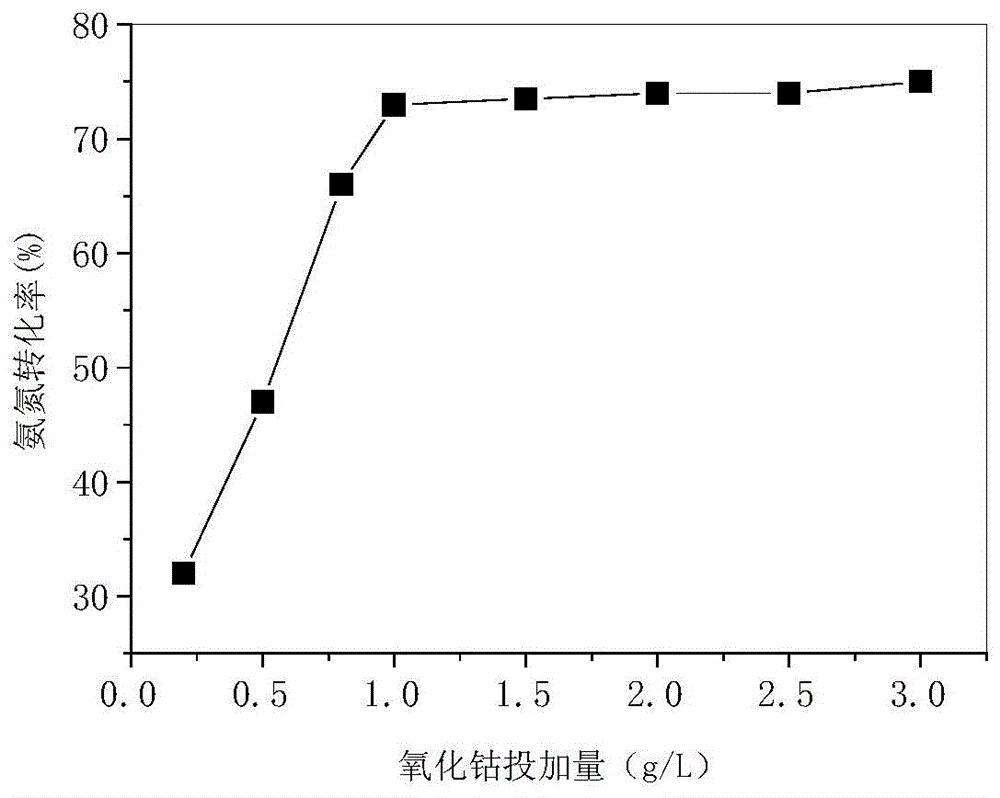

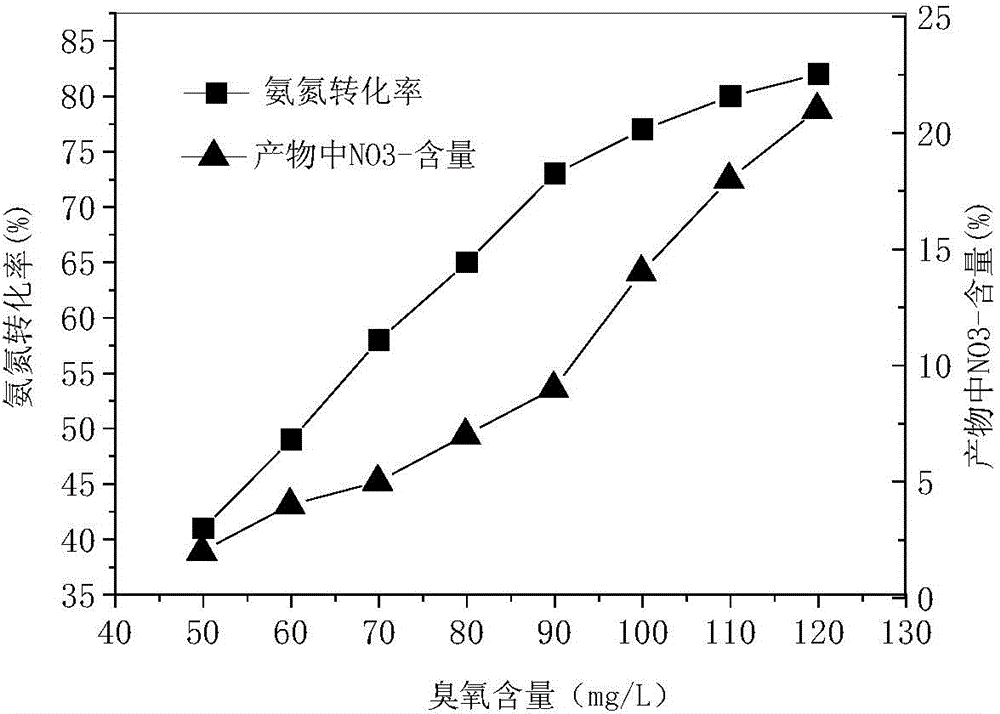

[0024] Metal oxide catalytic ozone oxidation treatment of ammonia nitrogen wastewater: the flow rate is 100mL / min O 2 Access initial NH 4 + -N concentration is 108mg / L in the solution and heated to 50°C. At this temperature, 1.0g / L cobalt oxide powder is added to the ammonia nitrogen wastewater, and the inlet gas is changed to mixed gas O 3 / O 2 (80mg / L of O 3 , The total flow rate is maintained at 100mL / min), the ammonia nitrogen in the water is catalyzed and oxidized. After continuous oxidation for 3 hours, 4 + -N conversion rate reached 65.2%, and NO in the product 3 -The content is 6.5%.

Embodiment 2

[0026] Metal oxide catalytic ozone oxidation treatment of ammonia nitrogen wastewater: the flow rate is 100mL / min O 2 Access initial NH 4 + -N concentration is 140mg / L in the solution and heated to 60°C. At this temperature, 0.8g / L cobalt oxide powder is added to the ammonia nitrogen wastewater, and the inlet gas is changed to mixed gas O 3 / O 2 (90mg / L of O 3 , The total flow rate is kept at 100mL / min), the ammonia nitrogen in the water is catalyzed and oxidized. After 7 hours of continuous oxidation, NH 4 + -N conversion rate reached 71.0%, and NO in the product 3 — The content is 9%.

Embodiment 3

[0028] Metal oxide catalytic ozone oxidation treatment of ammonia nitrogen wastewater: the flow rate is 100mL / min O 2 Access initial NH 4 + -N concentration is 100mg / L in the solution and heated to 80°C. At this temperature, 2.5g / L cobalt oxide powder is added to the ammonia nitrogen wastewater, and the inlet gas is changed to mixed gas O 3 / O 2 (110mg / L of O 3 , The total flow rate is maintained at 100mL / min), the ammonia nitrogen in the water is catalyzed and oxidized. After continuous oxidation for 6 hours, NH 4 + -N conversion rate reached 80.0%, and NO in the product 3 — The content is 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com