Method for producing aluminum ammonium sulfate crystal

A production method and technology of ammonium alum, applied in chemical instruments and methods, aluminum-sulfur compounds, aluminum sulfate, etc., can solve the problems of polluting groundwater, occupying a large space, and high water content, achieving low energy consumption, reducing waste residue discharge, The effect of less waste residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

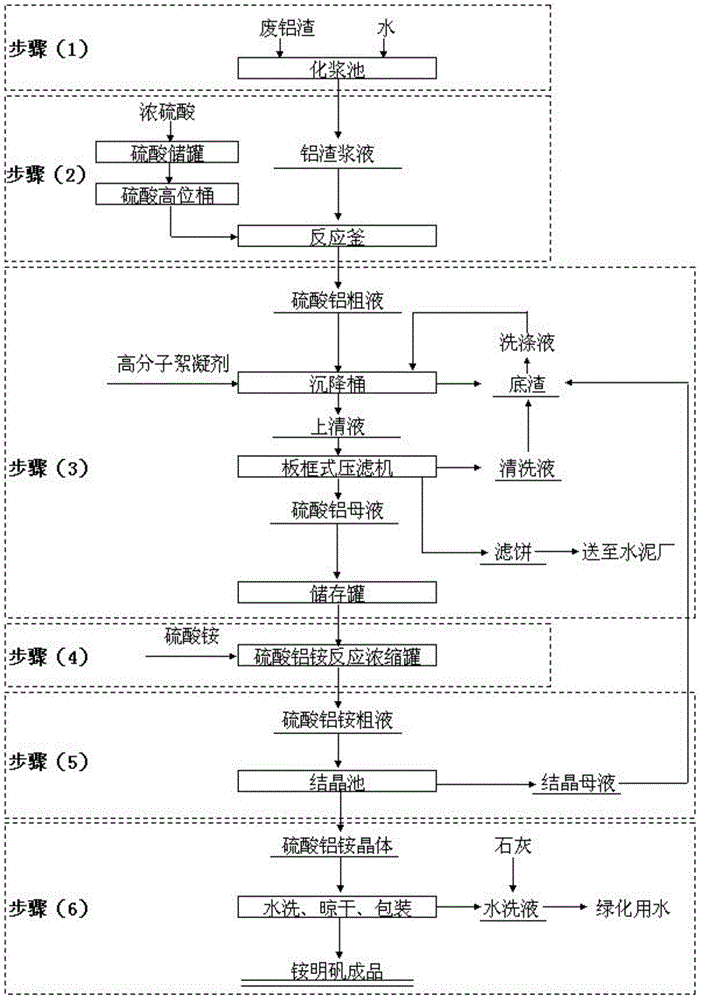

[0044] A kind of production method of ammonium alum, comprises following processing step:

[0045] (1) Pulping process: take the waste aluminum slag raw material with an alumina content of 20-60%, grind it into a particle size of 80 mesh, put it in the slurry tank, and stir while adding water to obtain 30-40 Baume Aluminum slag slurry;

[0046] (2) Aluminum sulfate crude liquid preparation process: first pump the aluminum slag slurry prepared in step (1) into the reactor, and then add concentrated sulfuric acid with a mass fraction of 98% that has been pumped into the high level tank into the reactor , the weight ratio of aluminum slag slurry and concentrated sulfuric acid is 1:1, close the reaction kettle, start the stirrer to stir, the stirring speed is 25 rpm, and the time is 5 minutes. When the pressure in the reaction kettle is 0.3~0.4MPa, Stop stirring, leave standstill for 2 hours, make aluminum sulfate thick liquid;

[0047] (3) Aluminum sulfate crude liquid sediment...

Embodiment 2

[0055] A kind of production method of ammonium alum, comprises following processing step:

[0056] (1) Pulping process: Take the waste aluminum slag raw material with an alumina content of 20-60%, grind it into a particle size of 100 mesh, put it in the slurry tank, and stir while adding water to obtain 30-40 Baume Aluminum slag slurry;

[0057] (2) Aluminum sulfate crude liquid preparation process: first pump the aluminum slag slurry prepared in step (1) into the reactor, and then add concentrated sulfuric acid with a mass fraction of 98% that has been pumped into the high level tank into the reactor , the weight ratio of aluminum slag slurry and concentrated sulfuric acid is 1:1, close the reactor, start the stirrer to stir, the stirring speed is 20 rpm, and the time is 35 minutes. When the pressure in the reactor is 0.3~0.4MPa, Stop stirring, leave standstill for 2 hours, make aluminum sulfate thick liquid;

[0058] (3) Aluminum sulfate crude liquid sedimentation and sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com