Composite type soft sealing method

A soft sealing and composite technology, applied in the direction of containers, packaging, transportation and packaging, etc., can solve the problems of poor sealing effect, achieve the effect of extending the length, overcoming the rupture of liquid-filled sealed bags, and overcoming elastic failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

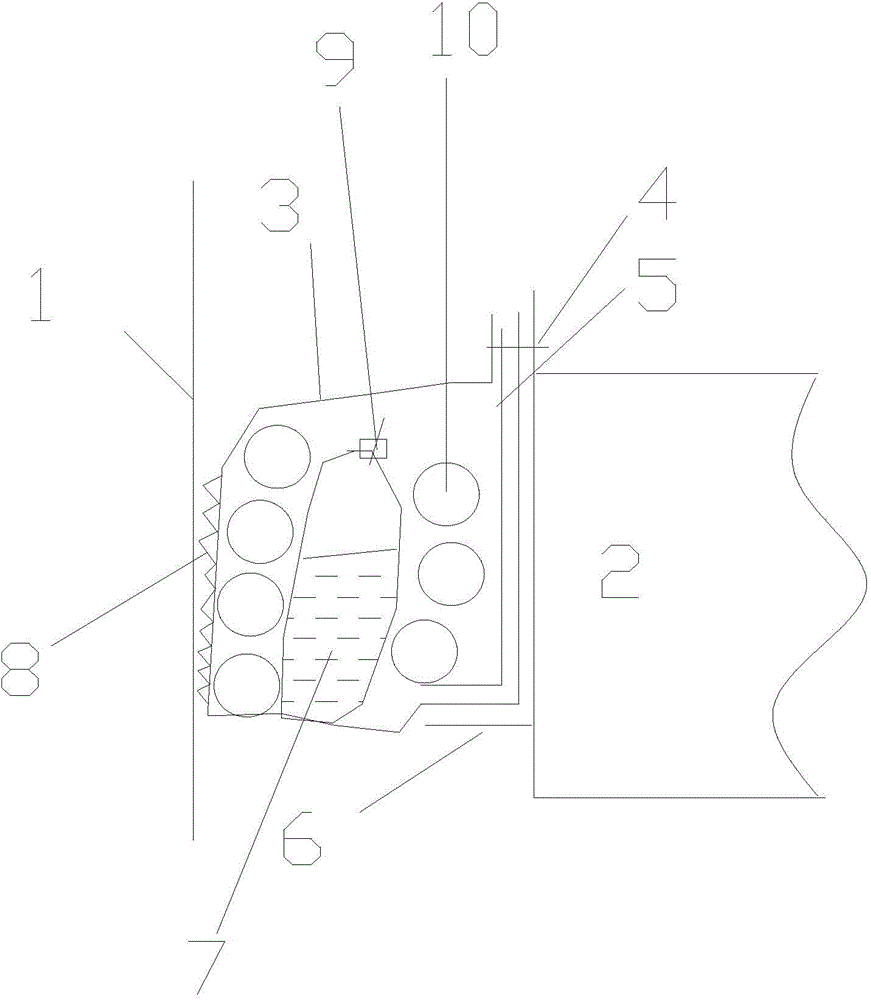

[0019] This patent adopts a composite soft seal structure, which assembles the elastic foam-filled seal and the liquid-filled seal together to give full play to the advantages of these two seals. At the same time, the length of the rubber bag is extended to increase the contact between the rubber bag and the tank wall area.

[0020] Such as figure 1 As shown, the soft sealing device is composed of three parts, namely elastic foam-filled rubber bag, liquid-filled rubber bag and elastic foam, in addition there are rubber bag fixing plate, liquid injection port of liquid-filled rubber bag and other accessories.

[0021] The liquid-filled rubber bag is placed in the middle of the whole device, and elastic foam is set on both sides or one side. The resilient foam filled side is placed adjacent to the side of the tank wall. When the gap between the tank wall and the floating plate is small, the gap between the liquid-filled rubber bag and the floating plate does not need to be ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com