Upper shear blade front pressing plate device of pendulum shear

A front platen and platen technology, applied in the field of metallurgical rolling, can solve problems such as poor operation and poor shear section quality, and achieve the effects of solving poor operation, improving product quality and reducing the number of shutdowns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

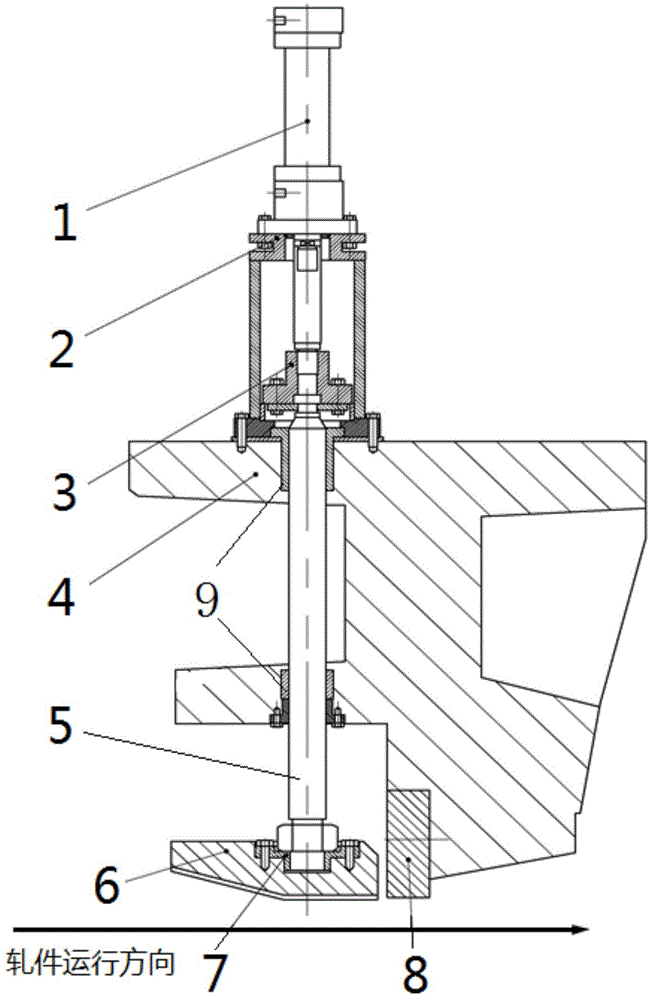

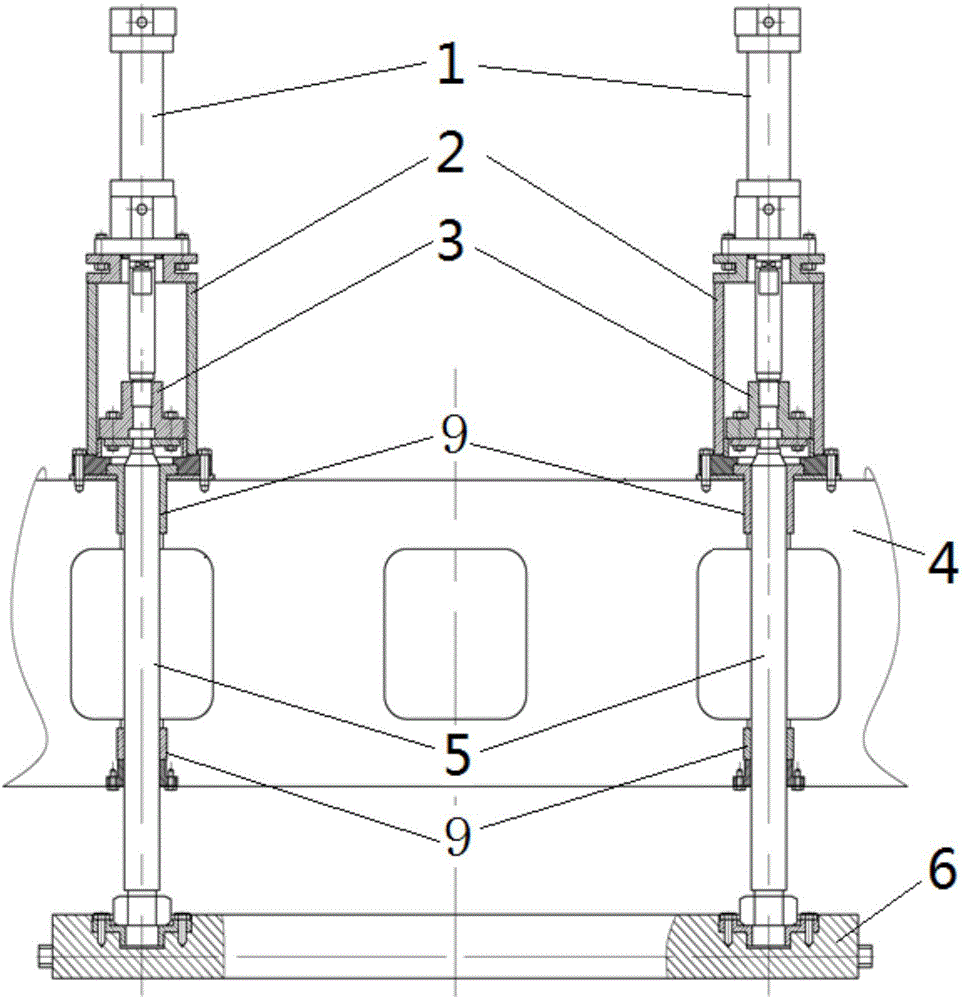

[0013] Such as figure 1 , figure 2 As shown, the structure of the device of the present invention is that an upper shearing edge 8 is installed at the sharp corner of the lower part of the upper tool rest 4, and a vertical coaxial through-hole is opened on the upper and lower hanging plates facing the rolling piece entering direction at the upper part of the upper tool rest 4. Hole, two through hole openings are respectively provided with a sliding sleeve 9, the two through holes and sliding sleeves 9 are jointly provided with a connecting rod 5; 2. The protective cover 2 is set coaxially with the sliding sleeve 9 and the connecting rod 5. The upper end of the protective cover 2 is fixedly connected with the front flange of the cylinder body of the hydraulic cylinder 1. The piston rod of the hydraulic cylinder 1 is connected downward with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com