Tape adhering jig for door frame decorating strip

A technology of adhesive strips and decorative strips, applied in the direction of material gluing, manufacturing tools, connecting components, etc., can solve the problems of insufficient adhesive force, time-consuming attachment, and large deviation of adhesive position, etc., to achieve standardized operations and uniform adhesive force , the effect of effective pasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

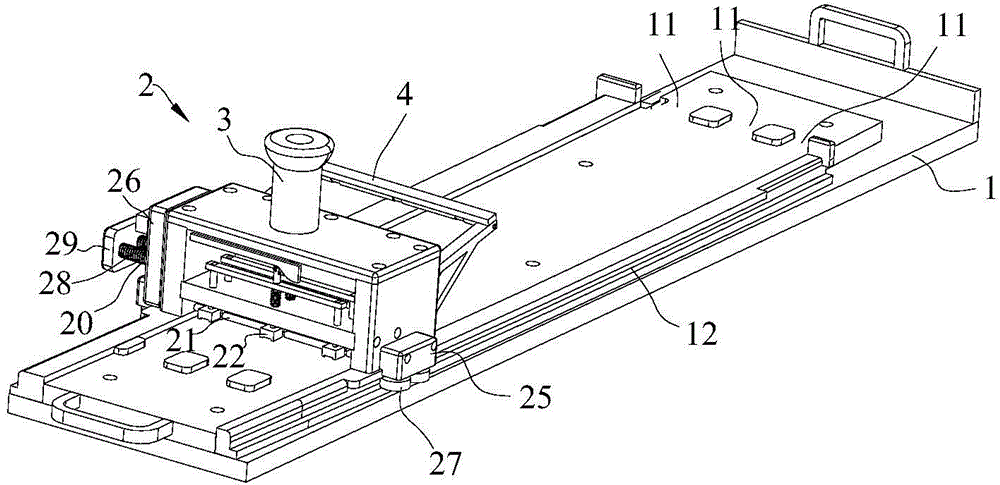

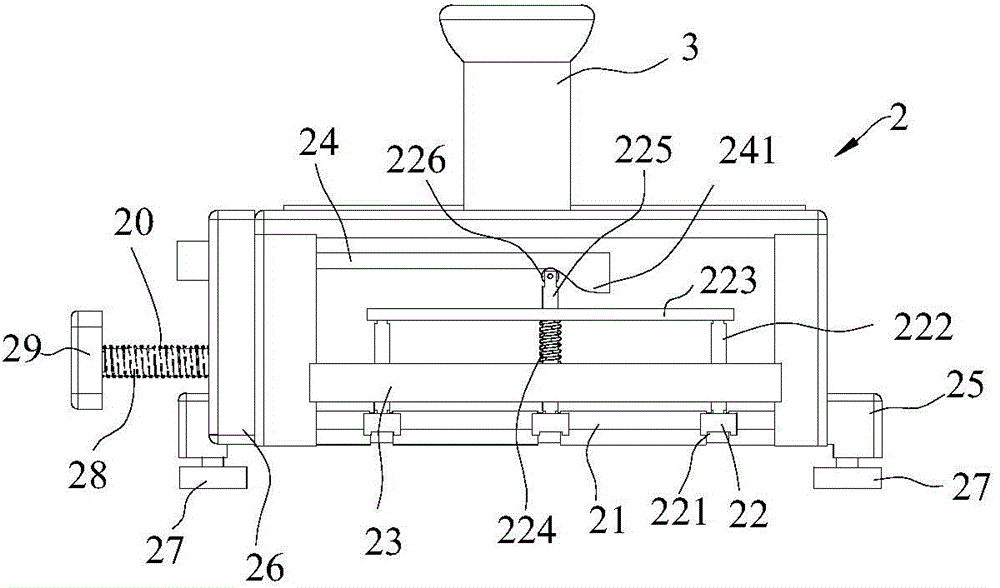

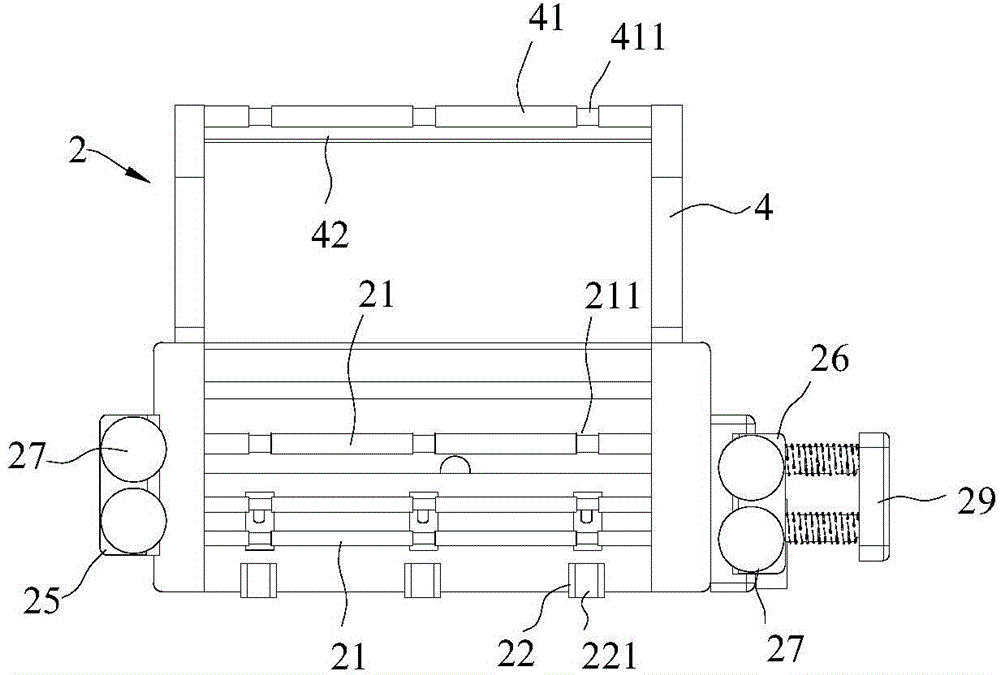

[0016] refer to Figure 1 to Figure 3 , the present invention provides a jig for attaching glue strips on door frame trim, which includes a fixed base 1 and a moving slide 2 that can slide laterally on the fixed base 1, and the top of the moving slide 2 is equipped with Push handle 3. The upper side of the fixed base 1 is provided with three installation positions 11 distributed along the transverse direction to place decorative strips. Rubber strip guide grooves 211 corresponding to each installation position 11 are provided, and a press block 22 corresponding to each installation position 11 is provided on the rear side of the horizontal shaft 21 on the moving slide 2, and the bottom of each press block 22 Rubber strip pressing groove 221 is provided. The moving slide 2 is provided with a guide frame 4 protruding to the front side, and the guide frame 4 is equipped with a guide cross shaft 41 across each installation position 11 and a guide cross bar parallel to the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com