Photovoltaic assembly battery string precise layout and bus bar efficient welding machine

A technology of photovoltaic modules and confluence belts, applied in the direction of photovoltaic power generation, circuits, electrical components, etc., can solve the problems of repetition, the beat is 24-32 seconds, the typesetting accuracy is not high, and there are many action processes, so as to achieve simple structure and low equipment cost The effect of low and high positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

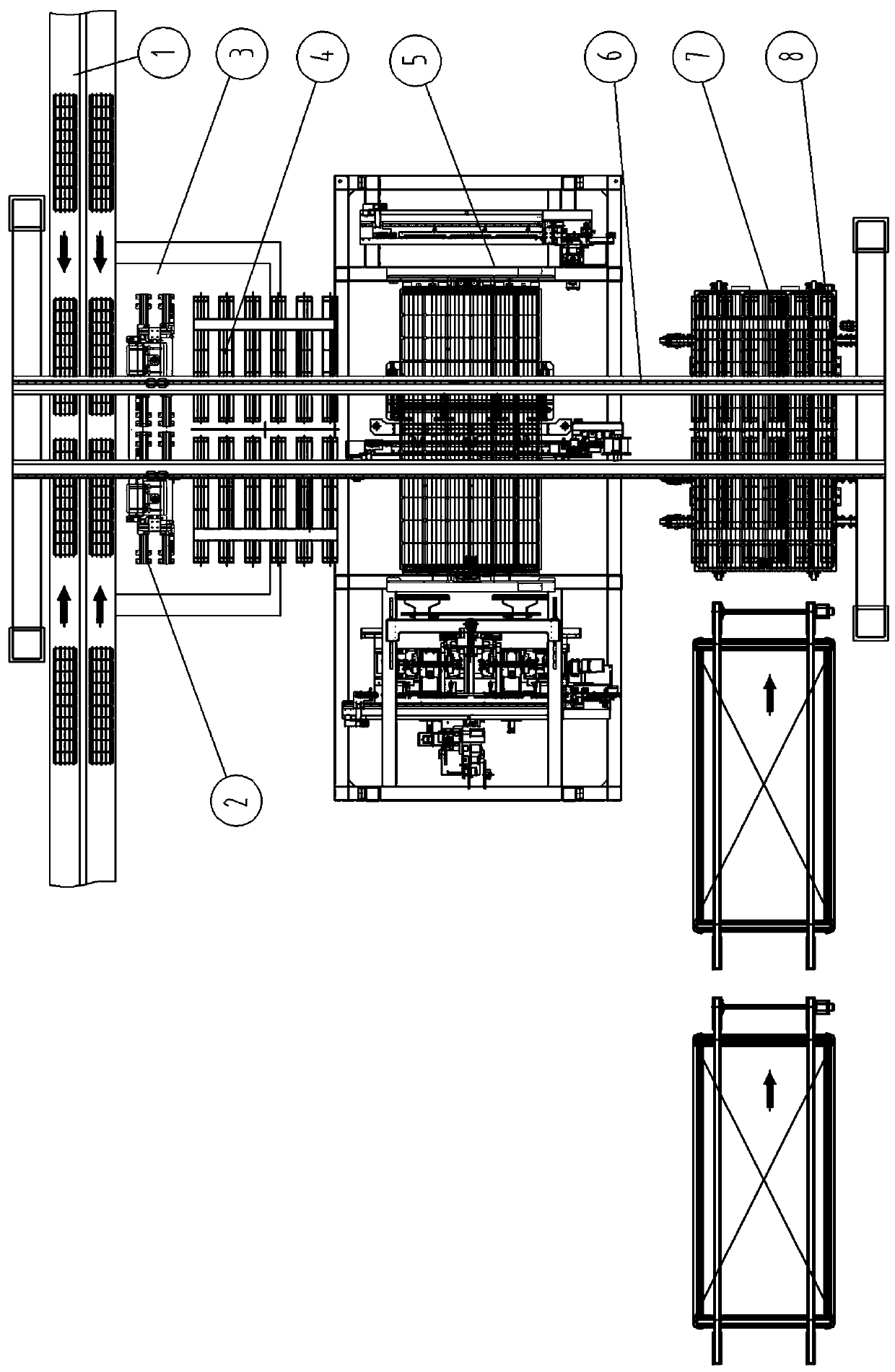

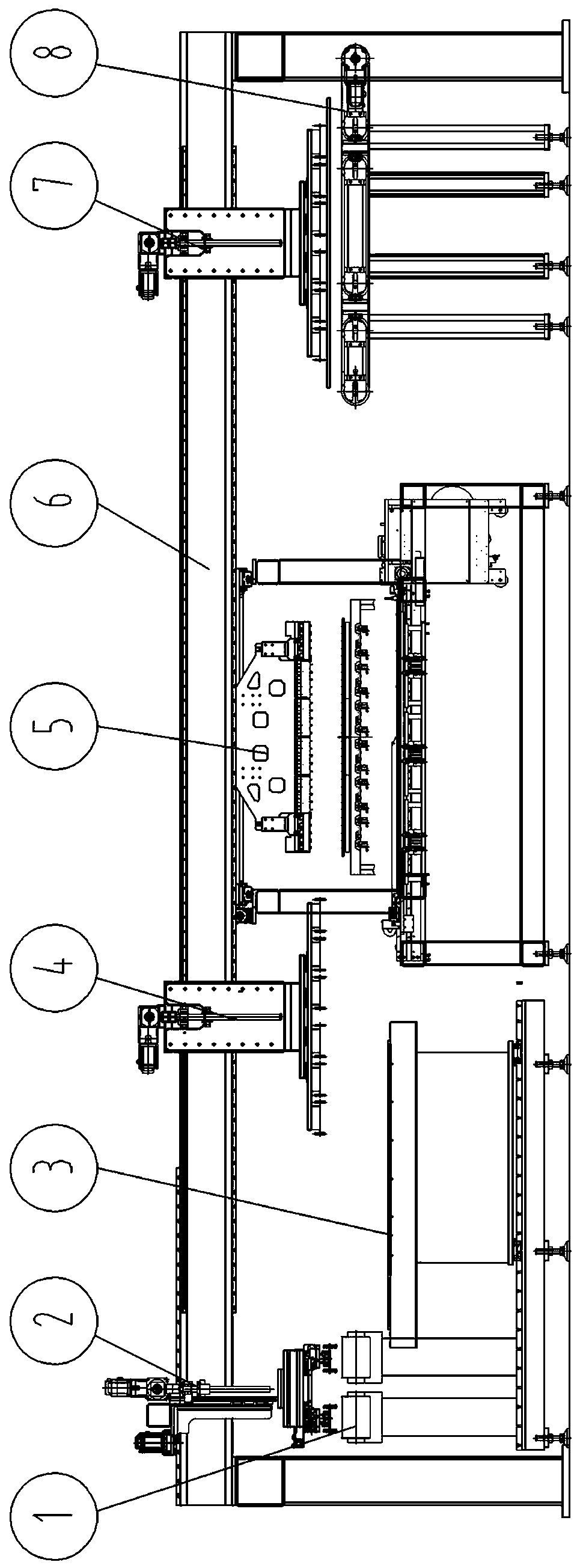

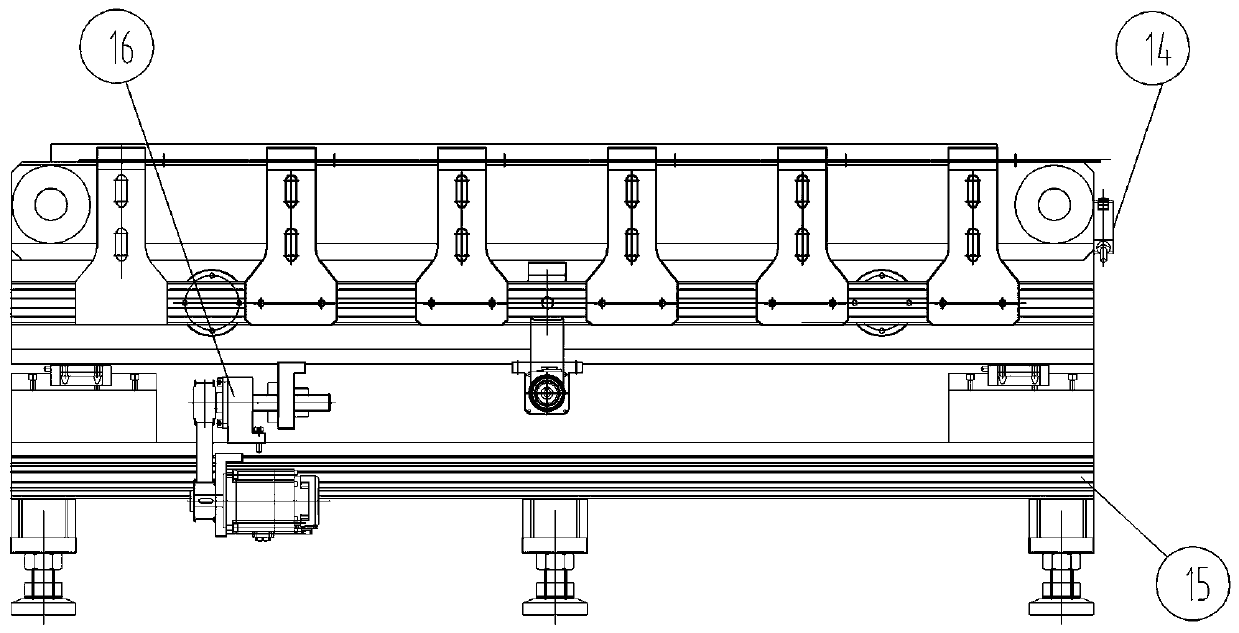

[0075] As shown in the figure, the present invention includes a conveying positioning device (1), a battery string translation adjustment manipulator (2), a buffer platform (3), a component feeding manipulator (4), a bus belt welding machine (5), a truss (6 ), the component unloading manipulator (7) and the material receiving and conveying platform (8), which are characterized in that the conveying positioning device (1) is arranged below the front end of the truss (6) in the length direction, and the truss above the conveying and positioning device (1) ( 6) The battery string translation adjustment manipulator (2) is set on the top, the buffer platform (3) is located below the rear end of the conveying positioning device (1), and the component feeding manipulator (4) is set on the upper truss (6) at the rear side of the cache platform (3) ), the component feeding manipulator (4) is equipped with a busbar welding machine (5) at the lower end of the rear truss (6), and the busba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com