Material pushing device for double-hook hooping machine

The technology of a double-hook stirrup machine and a pushing device is applied in the field of construction machinery and equipment, and can solve the problems of restricting the stable and high-speed operation of the double-hook stirrup machine, low work efficiency, time-consuming and labor-intensive, etc., so as to improve safety, reliability and production. Efficiency, low processing cost, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

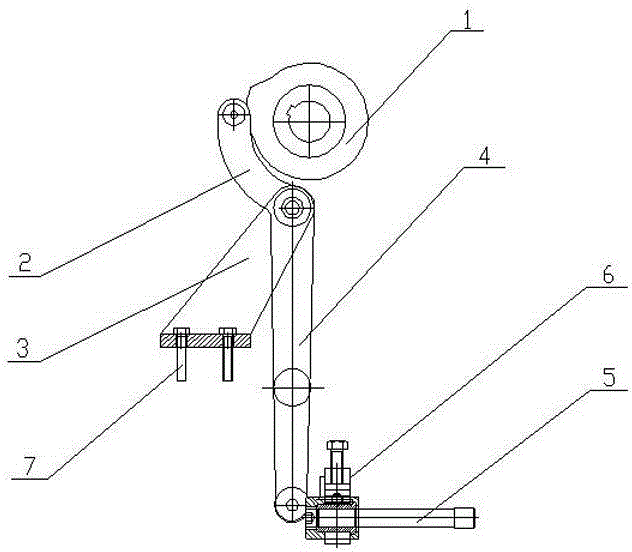

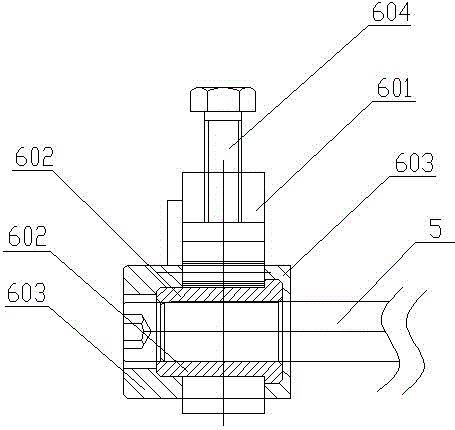

[0014] A pusher device for a double-hook stirrup machine, which is provided with a cam 1 driven by a driving device, and a cam top sleeve 2 is arranged on the motion track of the cam 1, and one end of the cam top sleeve 2 is hinged and fixed on the cam top sleeve. On the part 3, and one end of the cam top sleeve 2 and the cam top sleeve fixing part 3 is also fixedly connected with a connecting rod 4, and the bottom end of the connecting rod 4 is horizontally provided with a push rod 5 for pushing materials. The outer sleeve of the material rod 5 is provided with a guide shaft support 6 for limiting its up and down movement, and the cam top sleeve 2 can periodically drive the connecting rod 4 during the circular motion of the cam 1 so that the cam top sleeve 2 and the cam The hinged part of the top cover fixing part 3 is a fulcrum to move back and forth, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com