Die guide column straightening machine

A mold guide post and straightening machine technology, which is applied in the directions of forming tools, manufacturing tools, feeding devices, etc., can solve the problems of inability to quickly clamp the mold guide posts, high cost, and low straightening efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

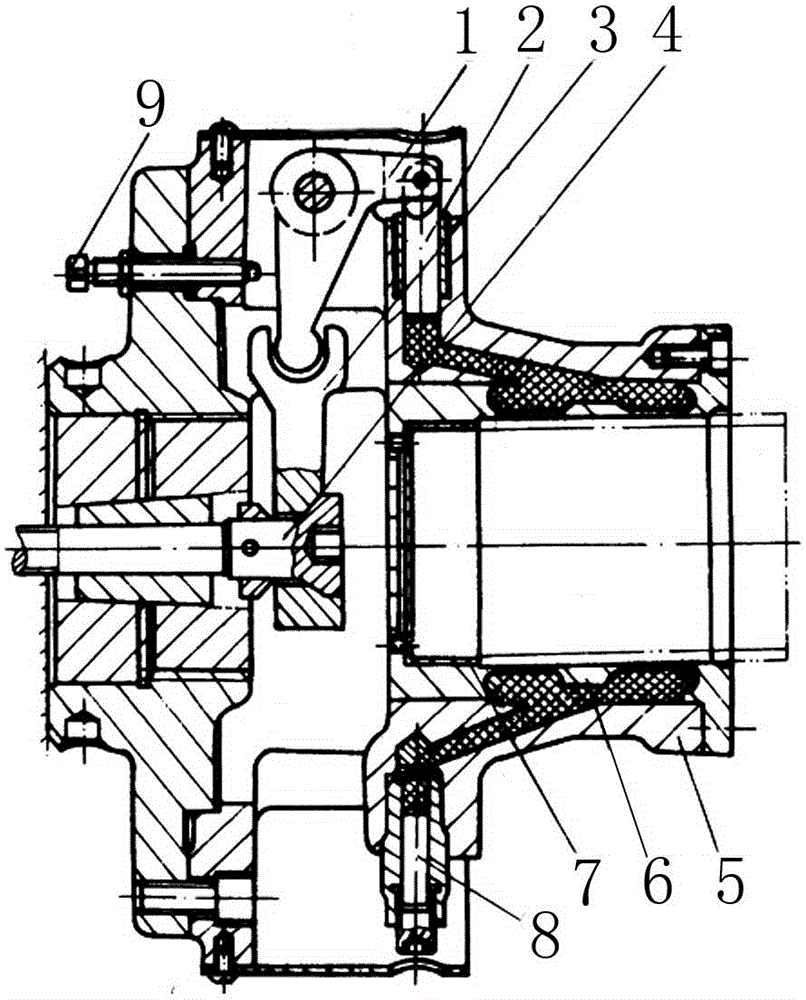

[0015] Embodiment one is basically as attached figure 1 Shown: The mold guide post straightening machine includes the frame, the indenter fixed on the frame and the clamping part perpendicular to the indenter. The indenter is used to straighten the mold guide post, and the clamping part is used for clamping The mold guide post, the clamping part includes the base body and the fixed block connected to the base body by screws, which is convenient for installation and disassembly, and also includes liquid plastic, sliding column 2, thin-walled expansion sleeve 6, and expansion sleeve set on the fixed block The pull rod 4 which is slidingly connected to the body 5 and the seat body, the connecting plate 3 connected and fixed with the pull rod, and the rocker arm 1 hinged with the connecting plate 3, the expansion sleeve body is provided with a passage for containing liquid plastics, and the expansion sleeve body is also provided with a The adjustment screw 8 connected to the openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com