Visible-light responding type magnetic compound photocatalyst with core-shell structure and preparation method and application thereof

A core-shell structure, photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of difficult separation of photocatalysts, easy photocorrosion, etc. The effect of improving photocorrosion resistance, excellent photocatalytic efficiency and photocatalytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

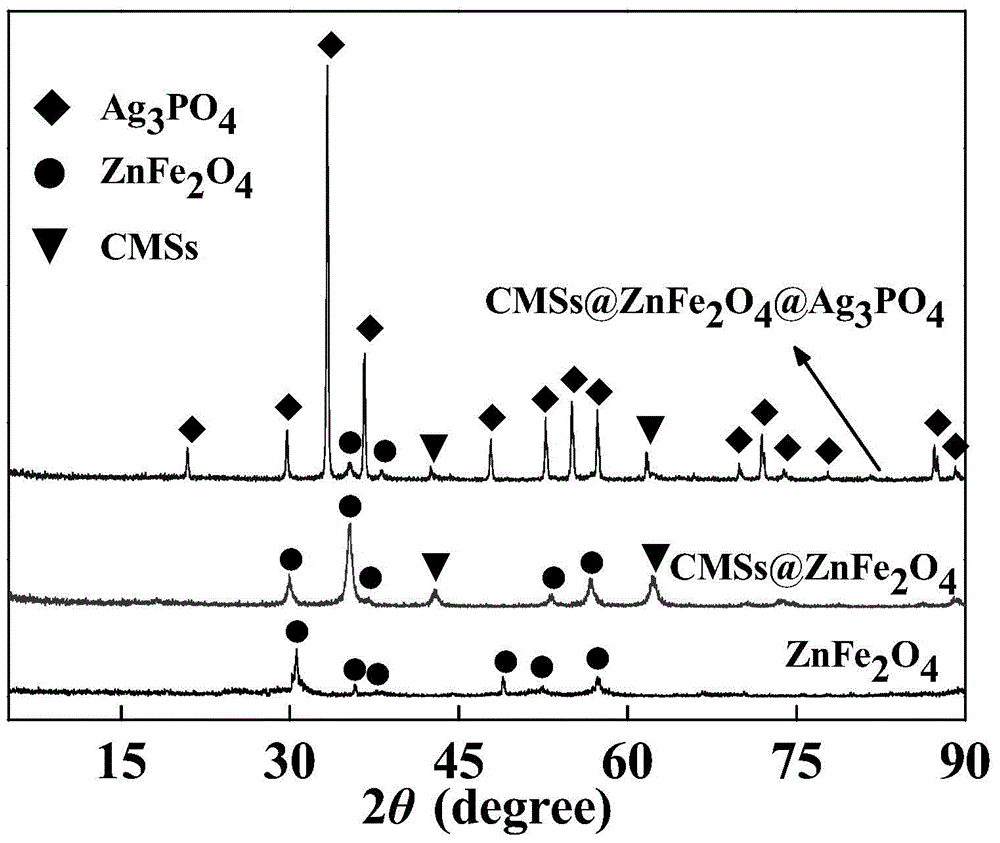

[0055] (1) Preparation of composite photocatalyst: first, ZnFe with uniform morphology and stable structure was prepared by solvothermal synthesis 2 o 4 , that is, 4mmol Fe(NO 3 ) 3 9H 2 O and 2mmol Zn(NO 3 ) 2 ·6H 2 O was dissolved in 60mL of ethylene glycol solvent, and mixed evenly under mechanical stirring, then 30mmol of crystalline sodium acetate was added, and the stirring was continued for 1h. After the reactor was naturally cooled to room temperature, the precipitate was repeatedly ultrasonically washed with absolute ethanol and ultrapure water, separated with a magnet, dried in a vacuum oven at 60°C for 12 hours, ground, and passed through an 80-mesh sieve. ZnFe 2 o 4 ;

[0056] Further preparation of CMSsZnFe by hydrothermal synthesis 2 o 4 , namely accurately weigh the ZnFe prepared in 2mmol step (1) 2 o 4 Disperse in 160mL solution with 10mmol of glucose dissolved, transfer it to a 200mL polytetrafluoroethylene-lined autoclave after uniform dispersion...

Embodiment 2

[0060] Same as embodiment 1, just add Zn(NO 3 ) 2 ·6H 2 The amount of O was 1.5 mmol. It can be seen from the test results that the removal efficiency of the composite material for 2,4-DCP reaches 96.84% after 150 minutes of light irradiation.

Embodiment 3

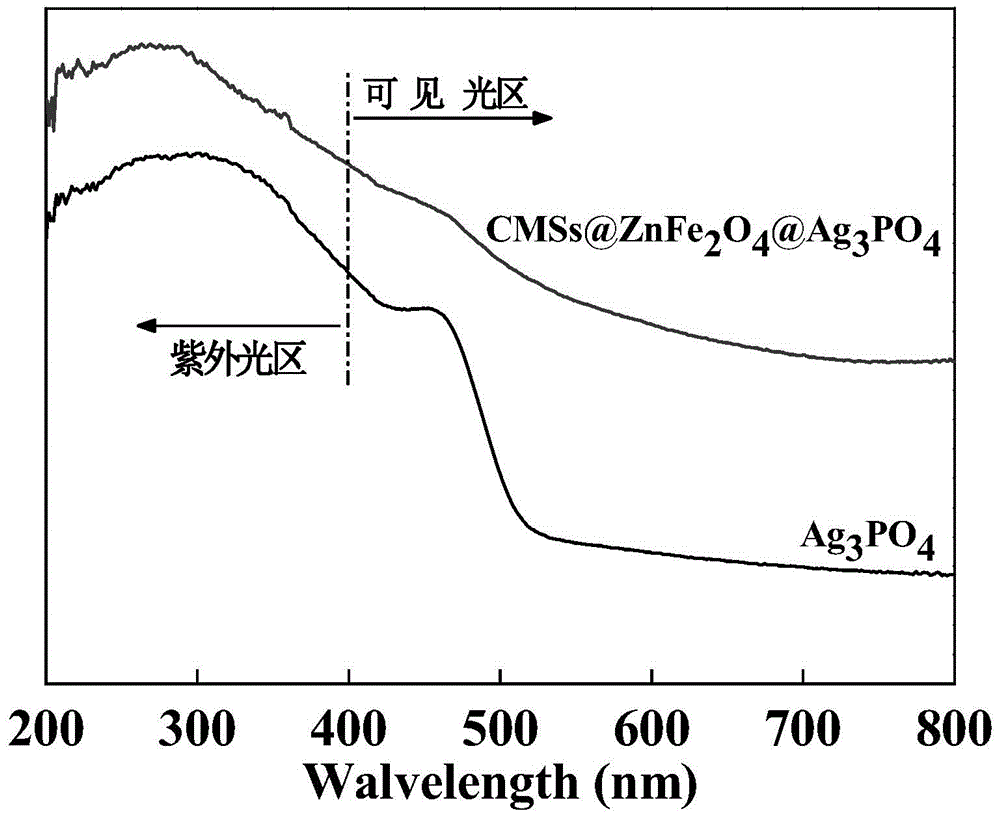

[0062] (1) Preparation of composite photocatalyst: ZnFe 2 o 4 and CMSsZnFe 2 o 4 The preparation process is the same as in Example 1. Then, CMSsZnFe was prepared by in situ precipitation method 2 o 4 Ag 3 PO 4 , the CMSsZnFe prepared in the 0.21g step (2) 2 o 4 Disperse in 100mL ethanol solution (V 乙醇 :V 水 =4:1) and sonicate for 10min, then add 50mL dissolved with 1.5mmol AgNO 3 Aqueous solution and mechanically stirred for 12h to make as much Ag as possible + bound in CMSsZnFe 2 o 4 Surface, then dissolve 50mL with 0.6mmol Na at a rate of 6mL / min 2 HPO 4 12H 2 The aqueous solution of O was added dropwise to the above-mentioned dispersion liquid and reacted for 1 h. After the precipitate obtained from the reaction was repeatedly washed with ultrapure water, it was magnetically separated, dried, ground, and passed through a 80-mesh sieve to obtain CMSs, ZnFe 2 o 4 and Ag 3 PO 4 The core-shell structure composite photocatalyst CMSsZnFe with a mass ratio of 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com