Magnesium fluoride-based catalyst and application of magnesium fluoride-based catalyst

A magnesium fluoride-based catalyst and catalyst technology, applied in the direction of physical/chemical process catalysts, dehydrohalogenation preparation, chemical instruments and methods, etc., can solve the problems of thermal stability deterioration, poor thermal stability, small specific surface area, etc., to achieve Rich pore structure, high thermal stability, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

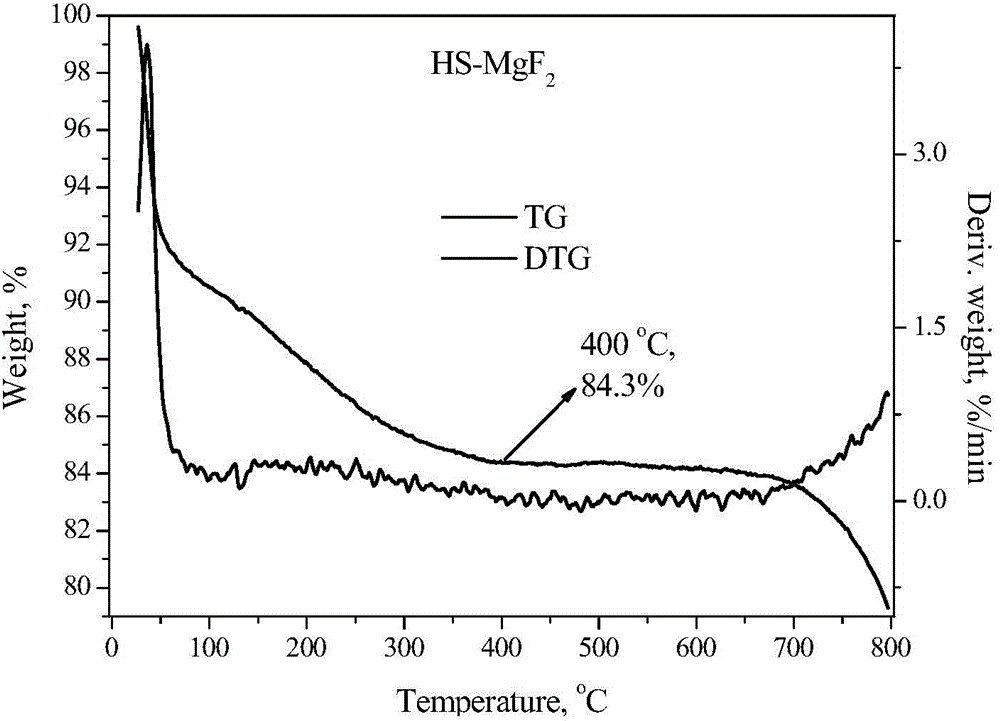

[0060] Example 1: Preparation of magnesium fluoride with high thermal stability and large specific surface area by liquid phase fluorination

[0061] Dissolve the mixture of 30.0g metallic magnesium insoluble salt and 15.0g surfactant in 200mL of water, and reflux the suspension at 100°C for 6h while stirring, then suction filter to obtain a solid, wash it with deionized water until neutral, Then it was dried at 100°C overnight to obtain a magnesium oxide precursor. Then the former body was roasted in a muffle furnace for 6 hours to obtain magnesium oxide with a large specific surface area. Slowly add the aqueous solution of fluorinating reagent dropwise to the aqueous solution containing the above-mentioned magnesia, then suction filter to obtain a solid, wash it with deionized water until it is neutral, then dry it at 100°C overnight, and put the former body in a muffle furnace Calcined for 4h to obtain magnesium fluoride.

[0062] Catalyst N 2 Adsorption and desorption p...

Embodiment 2

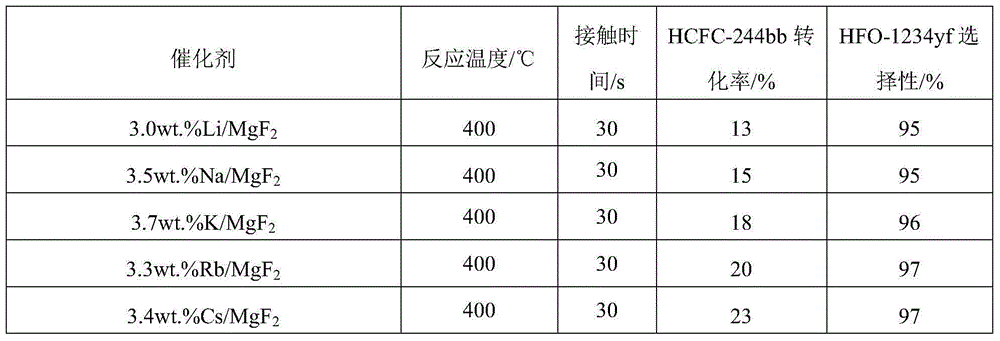

[0066] Dissolve 8.0g of alkali metal chlorides of Li, Na, K, Rb, and Cs in 100ml of distilled water to make a solution, and then add 2 / g of magnesium fluoride with large specific surface area, impregnated for 4 hours, dried at 80°C for more than 12 hours, and then roasted the precursor in a muffle furnace at 400°C for 6 hours to obtain a magnesium fluoride-based dehydrohalogenation catalyst.

[0067] A series of alkali metal-doped magnesium fluoride catalysts prepared were used as dehydrochlorination catalysts, and 60ml of catalysts were loaded into a fixed-bed tubular reactor with a diameter of Φ38mm. At a reaction temperature of 400°C, 2-chloro -1,1,1,2-Tetrafluoropropane passes through the catalyst bed with a residence time of 30s. The product is washed with water and alkali to remove HCl and HF, and then analyzed by gas chromatography. The analysis method is the area normalization method. After 24 hours of reaction, the results of dehydrochlorination are shown in Table 2...

Embodiment 3

[0071] Dissolve 12.0g of sulfates of transition metals Cr, Al, Fe, Zr in 100ml of distilled water to make a solution, and then add 2 / g of magnesium fluoride with large specific surface area, impregnated for 6 hours, dried at 100°C for more than 12 hours, and then roasted the precursor in a muffle furnace at 500°C for 6 hours to obtain a magnesium fluoride-based dehydrohalogenation catalyst.

[0072] The prepared series of transition metal-doped magnesium fluoride-based catalysts were used as dehydrofluorination catalysts, and 60ml of catalysts were loaded into a fixed-bed tubular reactor with a diameter of Φ38mm. At a reaction temperature of 350°C, 1, 1,1,3,3-Pentafluoropropane passes through the catalyst bed with a residence time of 30s. The product is washed with water and alkali to remove HCl and HF, and then analyzed by gas chromatography. The analysis method is the area normalization method. After reacting for 24 hours, the results of dehydrofluorination are shown in Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com