Preparation method of manganese zinc ferrite/bismuth oxide magnetic photocatalyst

A technology of manganese zinc ferrite and photocatalyst, which is applied in the direction of physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, chemical instrument and method, etc., which can solve the problem of low photocatalytic efficiency and difficulty in recycling, etc. problem, to achieve the effect of simple operation, sufficient solid-liquid mixing, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

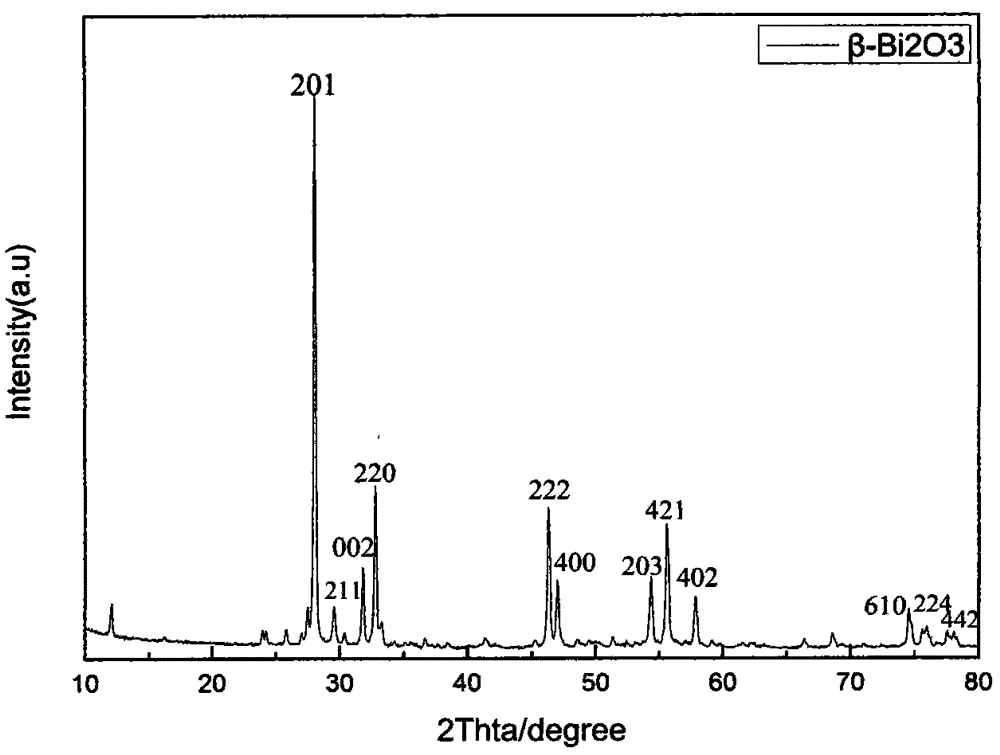

[0025] A kind of preparation method of manganese zinc ferrite / bismuth oxide composite magnetic photocatalyst, concrete steps are as follows:

[0026] (1) Preparation of manganese zinc ferrite

[0027] Weigh 1.91g of zinc sulfate, 2.77g of manganese sulfate, and 14.57g of ferric chloride hexahydrate and dissolve in water to obtain a solution, then add the zinc sulfate solution and ferric chloride solution into the manganese sulfate solution, and stir thoroughly to obtain a mixed solution. Weigh 16.40 g of ammonium oxalate and dissolve in water to obtain an ammonium oxalate solution. The mixed solution and the ammonium oxalate solution were heated to 80° C. under water bath conditions, and then the mixed solution was slowly added dropwise to the ammonium oxalate solution, and then the pH value was adjusted to 7 with ammonia water. The resulting oxalate precipitate was aged at room temperature for 12 hours, filtered, washed and dried, and finally placed in a muffle furnace and c...

Embodiment 2

[0033] A kind of preparation method of manganese zinc ferrite / bismuth oxide composite magnetic photocatalyst, concrete steps are as follows:

[0034] The (1) step is the same as embodiment 1.

[0035] The (2) step is the same as embodiment 1.

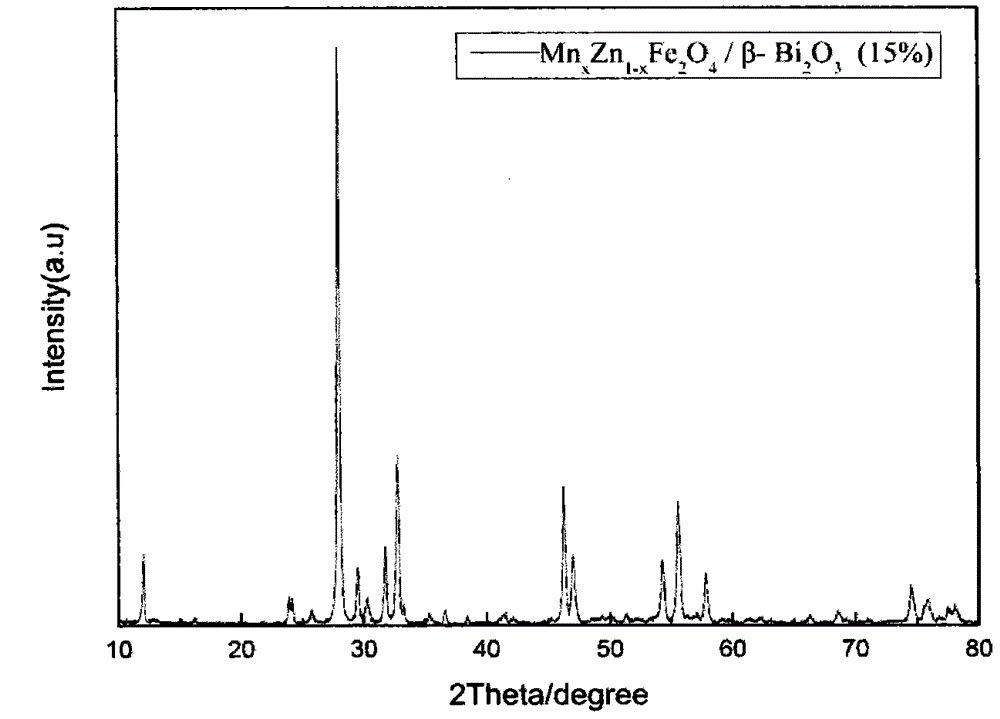

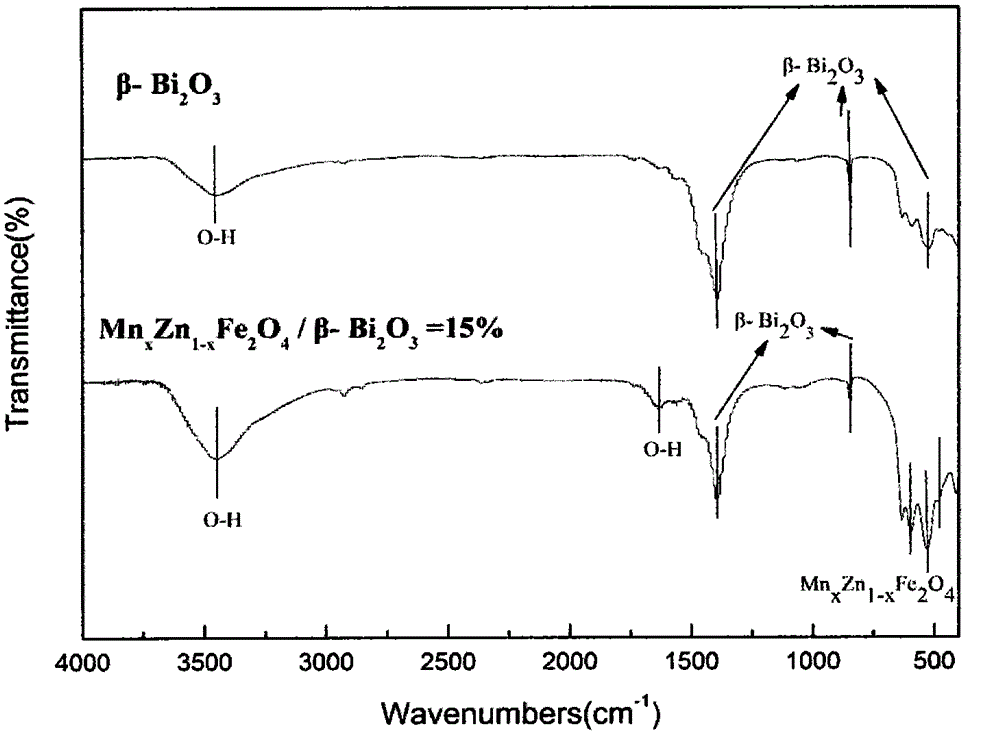

[0036] In step (3), take an appropriate amount of manganese zinc ferrite according to the mass ratio of manganese zinc ferrite and bismuth oxide as 15:100, add it to the bismuth oxide precursor prepared in step (2), and mechanically stir for 2 hours. The precursor of the gray manganese zinc ferrite / bismuth oxide composite magnetic photocatalyst was obtained. The precursor was filtered, washed, and dried in an oven at 60°C. The dried precursor was placed in a muffle furnace and calcined at 380° C. for 10 minutes, then taken out immediately, and the manganese zinc ferrite / bismuth oxide composite magnetic photocatalyst was obtained after cooling.

Embodiment 3

[0038] A kind of preparation method of manganese zinc ferrite / bismuth oxide composite magnetic photocatalyst, concrete steps are as follows:

[0039] The (1) step is the same as embodiment 1.

[0040] The (2) step is the same as embodiment 1.

[0041] In step (3), take an appropriate amount of manganese zinc ferrite according to the mass ratio of manganese zinc ferrite and bismuth oxide as 20:100, add it to the bismuth oxide precursor prepared in step (2), and mechanically stir for 3 hours. The precursor of the gray manganese zinc ferrite / bismuth oxide composite magnetic photocatalyst was obtained. The precursor was filtered, washed, and then dried in an oven at 60°C. The dried precursor was placed in a muffle furnace and calcined at 400° C. for 10 minutes, then taken out immediately, and the manganese zinc ferrite / bismuth oxide composite magnetic photocatalyst was obtained after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com