Environment-friendly manganese-cobalt-aluminum composite oxide mercury removal and denitration catalyst and preparation method thereof

A composite oxide, environment-friendly technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as restricting the application of manganese oxide catalysts, and achieve Low cost, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

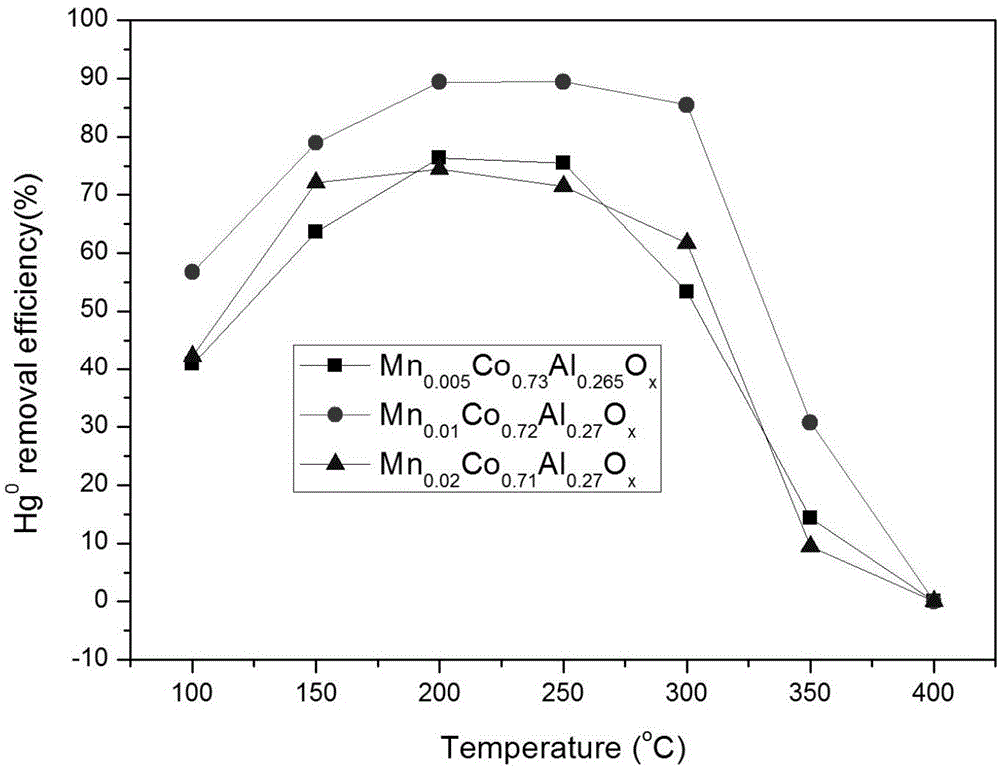

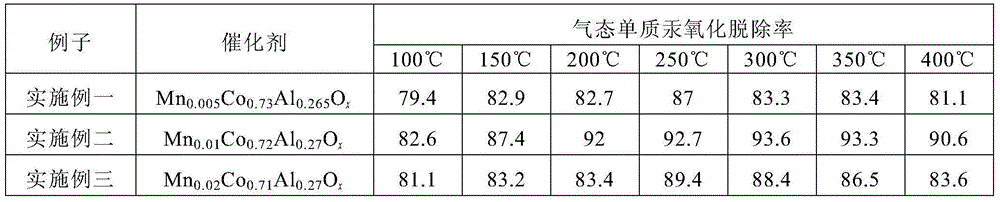

Embodiment 1

[0024] A manganese-cobalt-aluminum oxide denitrification synergistic demercury catalyst, the ratio of raw material components is: manganese nitrate with a metal element content of 0.5% of the molar percentage of the catalyst metal element, and a content of 73% of the catalyst metal element mole percentage of cobalt nitrate, and the balance is aluminum nitrate.

[0025] A method for preparing a manganese-cobalt-aluminum oxide denitrification synergistic demercury catalyst, comprising the following steps:

[0026] Step 1. Dissolving cobalt nitrate and aluminum nitrate in water with 100-200 times molar weight at room temperature, stirring to form a transparent solution. Then dilute 50% manganese nitrate solution at room temperature to a solution of 0.01mol / L, accurately measure a certain volume of manganese nitrate solution with a pipette and pour it into the mixed salt solution of cobalt and aluminum, wherein the manganese content is the catalyst metal element mole percent The ...

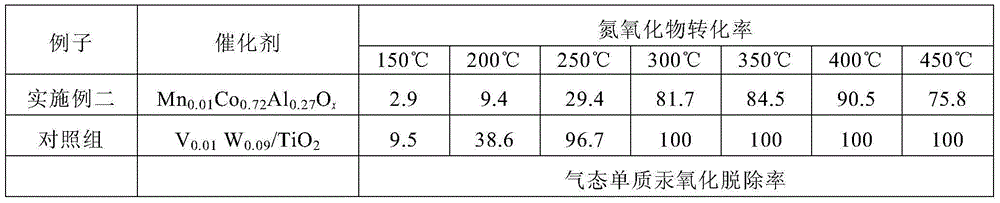

Embodiment 2

[0034] A manganese-cobalt-aluminum oxide denitrification synergistic demercury catalyst, the raw material component ratio is: manganese nitrate with a metal element content of 1% of the catalyst metal element mole percentage, and a catalyst metal element mole percentage content of 72% of cobalt nitrate, and the balance is aluminum nitrate.

[0035] A method for preparing a manganese-cobalt-aluminum oxide denitrification synergistic demercury catalyst, comprising the following steps:

[0036] Step 1. Dissolving cobalt nitrate and aluminum nitrate in water with 100-200 times molar weight at room temperature, stirring to form a transparent solution. Then dilute 50% manganese nitrate solution at room temperature to a solution of 0.01mol / L, accurately measure a certain volume of manganese nitrate solution with a pipette and pour it into the mixed salt solution of cobalt and aluminum, wherein the manganese content is the catalyst metal element mole percent content of 1%, the cobalt...

Embodiment 3

[0045] A manganese-cobalt-aluminum oxide denitrification synergistic demercury catalyst, the proportion of raw material components is: manganese nitrate with a metal element content of 2% of the catalyst metal element molar percentage, and a catalyst metal element molar percentage content of 71% of cobalt nitrate, and the balance is aluminum nitrate.

[0046] A method for preparing a manganese-cobalt-aluminum oxide denitrification synergistic demercury catalyst, comprising the following steps:

[0047] Step 1. Dissolving cobalt nitrate and aluminum nitrate in water with 100-200 times molar weight at room temperature, stirring to form a transparent solution. Then dilute 50% manganese nitrate solution at room temperature to a solution of 0.01mol / L, accurately measure a certain volume of manganese nitrate solution with a pipette and pour it into the mixed salt solution of cobalt and aluminum, wherein the manganese content is the catalyst metal element mole percent The cobalt con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com