Compound modified bentonite

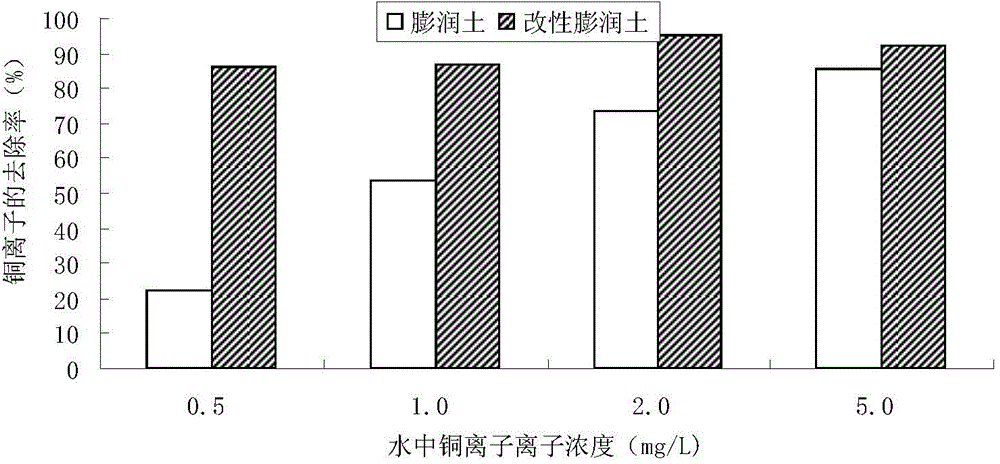

A technology of composite modification and bentonite, applied in water/sludge/sewage treatment, adsorption water/sewage treatment, other chemical processes, etc., can solve the problem of limited selective adsorption capacity, unsatisfactory adsorption effect, and unsatisfactory adsorption capacity of pollutants. Improvement and other issues, to achieve good adsorption effect, simple modification method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A composite modified bentonite, comprising sulfonated thiacalix[4]arene, cetyltrimethylammonium bromide and calcium-based bentonite, the content of which is: 4.23 grams of sulfonated thiacalix[4]arene, deca 1.69 grams of hexaalkyltrimethylammonium bromide and 94.08 grams of calcium bentonite. Its preparation method is:

[0017] 1. Weigh 94.08 grams of calcium-based bentonite, dry at 50°C for 4 hours, pass through a 100-200 mesh sieve and set aside.

[0018] 2. Weigh 1.69 g of cetyltrimethylammonium bromide, dissolve it in 200 ml of deionized water, and vibrate ultrasonically for 1 hour to obtain an aqueous solution of cetyltrimethylammonium bromide.

[0019] 3. Add the above dried and sieved bentonite to the aqueous solution of cetyltrimethylammonium bromide, and stir at 25°C for 24 hours.

[0020] 4. Then add 4.23 g of sulfonated thiacalix[4]arene, stir at 25°C for 24 hours, finally filter and separate, rinse with water three times, and dry at 50°C for 4 hours to obt...

Embodiment 2

[0023] A composite modified bentonite comprising sulfonated thiacalix[4]arene, cetyltrimethylammonium bromide and calcium-based bentonite, the content of which is: 10.4 grams of sulfonated thiacalix[4]arene, decaps 10.35 grams of hexaalkyltrimethylammonium bromide and 79.25 grams of calcium bentonite. Its preparation method is:

[0024] 1. Weigh 79.25 grams of calcium-based bentonite, dry at 50°C for 4 hours, pass through a 100-200 mesh sieve and set aside.

[0025] 2. Weigh 10.35 g of cetyltrimethylammonium bromide, dissolve it in 200 ml of deionized water, and oscillate ultrasonically for 1 hour to obtain an aqueous solution of cetyltrimethylammonium bromide.

[0026] 3. Add the above dried and sieved bentonite to the aqueous solution of cetyltrimethylammonium bromide, and stir at 25°C for 24 hours.

[0027] 4. Then add 10.4 g of sulfonated thiacalix[4]arene, stir at 25°C for 24 hours, and finally filter and separate, rinse with water three times, and dry at 50°C for 4 hou...

Embodiment 3

[0029] A composite modified bentonite, comprising sulfonated thiacalix[4]arene, cetyltrimethylammonium bromide and calcium-based bentonite, the content of which is: 7 grams of sulfonated thiacalix[4]arene, ten 5 grams of hexaalkyltrimethylammonium bromide and 88 grams of calcium bentonite. Its preparation method is:

[0030] 1. Weigh 88 grams of calcium-based bentonite, dry at 50°C for 4 hours, pass through a 100-200 mesh sieve and set aside.

[0031] 2. Weigh 5 grams of cetyltrimethylammonium bromide, dissolve it in 200 ml of deionized water, and oscillate ultrasonically for 1 hour to obtain an aqueous solution of cetyltrimethylammonium bromide.

[0032] 3. Add the above dried and sieved bentonite to the aqueous solution of cetyltrimethylammonium bromide, and stir at 25°C for 24 hours.

[0033] 4. Then add 7 grams of sulfonated thiacalix[4]arene, stir at 25°C for 24 hours, and finally filter and separate, rinse with water three times, and dry at 50°C for 4 hours to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com