Illumination withering method of black tea

A technology of withering and black tea, applied in the field of tea making, can solve the problems of restricting the development of black tea industry, bitter taste, low aroma, etc., and achieve the effect of enhancing sweetness, reducing bitterness, increasing concentration and persistence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for black tea light withering, the steps are as follows:

[0021] (1) Fresh leaf raw materials are picked, and the tenderness is controlled within one bud with three or four leaves;

[0022] (2) Spread the fresh leaf raw materials in the withering equipment, the thickness of the spread leaves is ≤10cm, and obtain the spread leaves;

[0023] (3) Use yellow light: wavelength 585 or -590nm, or orange light: wavelength 590 or 600nm, or red light: wavelength 630 or 640nm monochromatic light on the top of the spread leaves to control the light tube and the spread leaves. The surface distance is ≤11cm, the light intensity on the spread leaf surface is ≥220 or 230 or 240Lx, the irradiation time is ≥5 or 67h, the controlled withering temperature is 25 or 27 or 29 or 31 or 33 or -35°C, and the time is 8 or 9 or 10 or 11 or 12h, make its water content to 58 or 60 or 62%, obtain withered leaves;

[0024] (4) Knead (cut) the withered leaves, ferment at a temperature of 30...

Embodiment 2

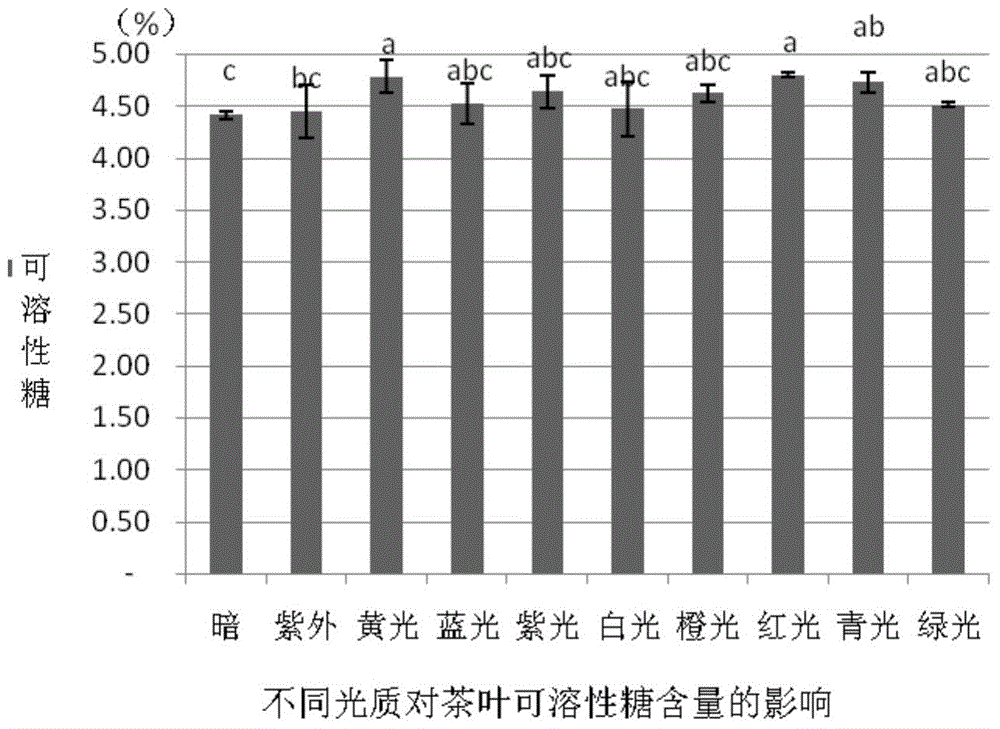

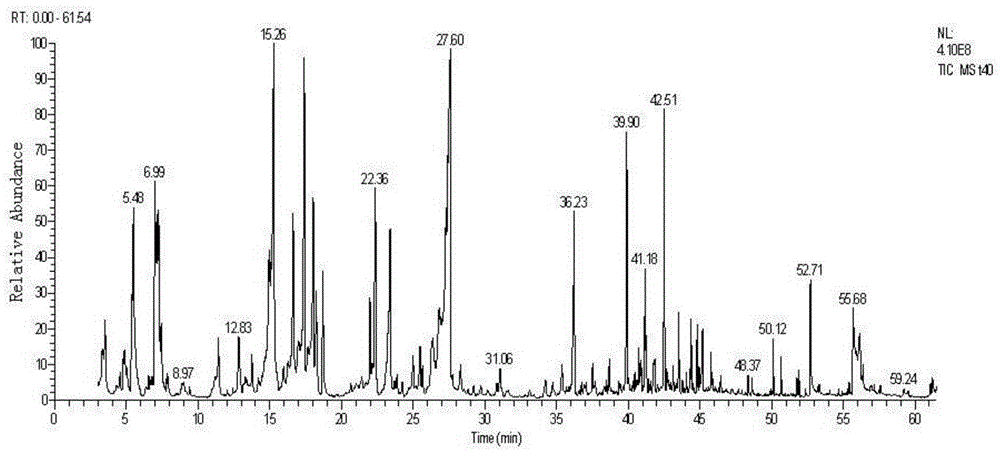

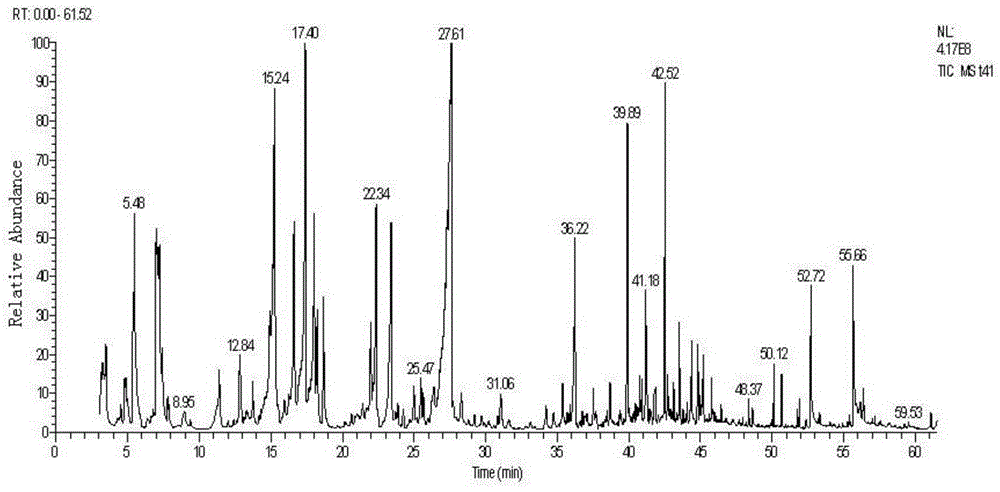

[0026] Effects of different light quality withering on the quality of black tea

[0027] With one bud and one two leaves of Fuding Dabai tea variety as raw materials, it is operated according to the technological process of withering, rolling, fermenting and drying. Treat with ultraviolet light, yellow light, blue light, orange light, white light (control), purple light, red light, blue light, green light and no light in experimental black tea withering box (tank length 100cm, width 50cm, height 60cm) Withered leaves (Table 1). During the withering process, the light time is 9 hours, the leaves are turned every 1.5 hours to make the light even, and the blowing time is 5-6 hours. The temperature of the withering room is 26°C, and the relative air humidity is 55-65%. After withering, the withered leaves were kneaded and cut 5 times with a rotor crushed red tea kneading and cutting machine (type 6CRQ-20, Fuyang Tea Machinery Co., Ltd.). The fermentation temperature was 30°C, t...

Embodiment 3

[0050] Embodiment 3: the influence of light intensity on the quality of black tea

[0051] With one bud and one two leaves of Fuding Dabai tea variety as raw materials, it is operated according to the technological process of withering, rolling, fermenting and drying. Withered leaves were treated with yellow light in an experimental black tea withering box (the length of the tank body was 100 cm, the width was 50 cm, and the height was 60 cm). During the withering process, the light time is 9 hours, the leaves are turned every 1.5 hours to make the light even, and the blowing time is 5-6 hours. The temperature of the withering room is 26°C, and the relative air humidity is 55-65%. After withering, the withered leaves were kneaded and cut 5 times with a rotor crushed red tea kneading and cutting machine (type 6CRQ-20, Fuyang Tea Machinery Co., Ltd.). The fermentation temperature was 30°C, the relative air humidity was 80% (JFF-400 humidifier, Wuhan Mingyi Technology Co., Ltd....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com