Controller For Machine Tool Including Main Shafts

A technology of control device and spindle motor, which is applied in the direction of AC motor control, control system, program control, etc. It can solve the problems of different acceleration and deceleration conditions of the spindle motor, twisted and damaged workpieces, complex mechanical structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

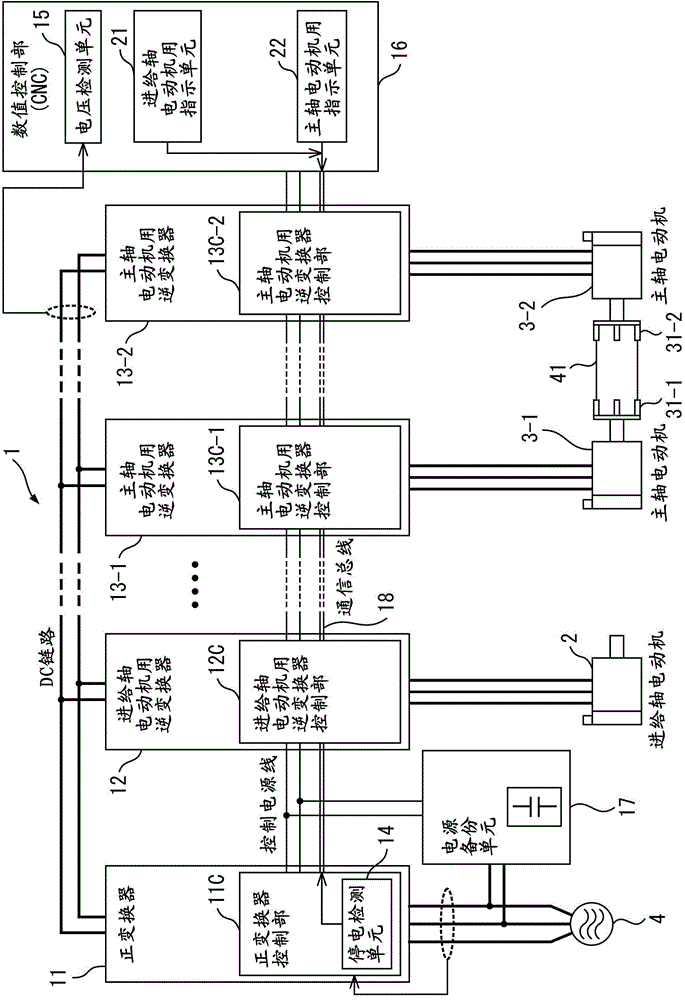

Method used

Image

Examples

no. 2 example

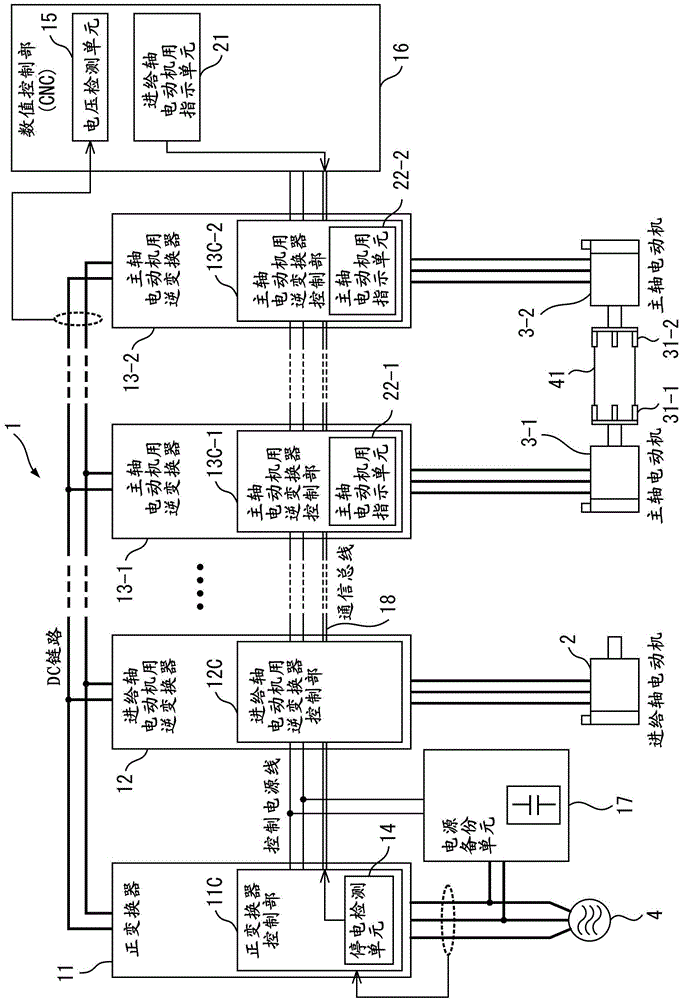

[0070] Regarding the second embodiment, the constituent elements other than the above-mentioned constituent elements are the same as those of the first embodiment, and therefore description thereof will be omitted.

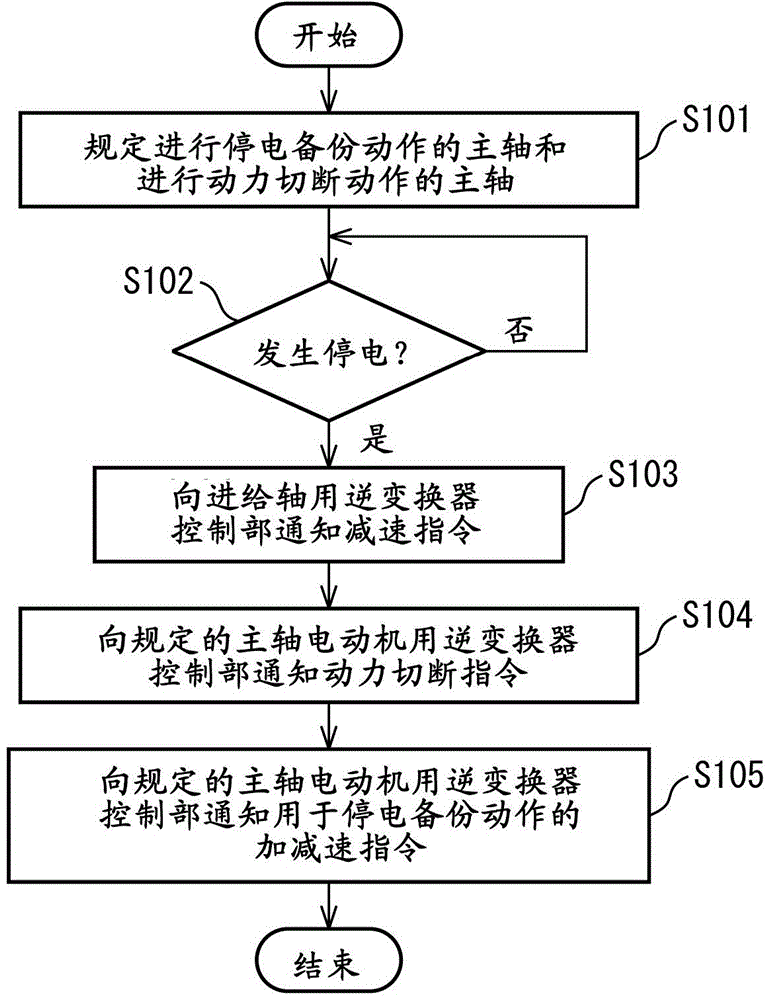

[0071] Figure 5 It is a flowchart showing the flow of operations of the machine tool control device of the second embodiment. Below, the description is in Figure 4 In the example shown, the operation of the control device 1 when a power failure occurs on the side of the AC power supply 4 during machining of the workpiece 41 is shown.

[0072] First, in step S201, in the numerical control unit 16 functioning as a higher-level control unit for the first spindle motor inverter control unit 13C-1 and the second spindle motor inverter control unit 13C-2, In its control program, it is specified as the inverse converter 13-1 for the first spindle motor and the inverse converter for the second spindle motor when a power failure occurs on the side of the AC power suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com