Electrically conductive paste and base material with electrically conductive film

A technology of conductivity and paste, which is applied in the field of substrates with conductive films, can solve problems such as high cost, deterioration of conductivity, and damage of conductivity, and achieves suppression of deterioration of conductivity, excellent conductivity, and high conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

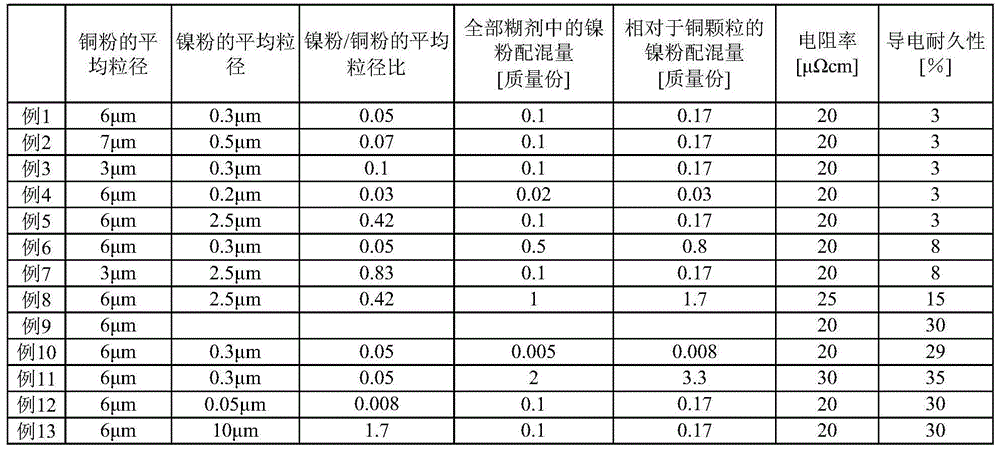

[0076] Hereinafter, the present invention will be described in further detail through examples, but the present invention is not limited to these examples. Examples 1 to 8 are examples, and examples 9 to 13 are comparative examples. In addition, the average particle diameter of metal particle (copper particle) and base metal particle (nickel particle), the thickness of a conductive film, and resistivity were measured using the apparatus shown below, respectively.

[0077] (The average particle size)

[0078] Copper particles were used as metal particles. The particle size of the copper particles is calculated as follows: The Feret diameter of 100 particles randomly selected from the SEM image obtained by SEM (manufactured by HITACHI HIGH-TECHNOLOGIES CORPORATION, S-4300) is measured, and the Feret diameter of each copper particle is calculated. When the radial direction with the maximum diameter is set as the major axis, and the axis perpendicular to the major axis is set as...

example 1

[0084] After adding 3.0 g of formic acid and 9.0 g of a 50% by mass hypophosphorous acid aqueous solution to a glass beaker, the beaker was placed in a water bath and maintained at 40°C. 5.0 g of copper particles (manufactured by Mitsui Metal Mining Co., Ltd., trade name: 1400YP) were gradually added to the beaker with an average particle size of 6 μm, and stirred for 30 minutes to obtain a copper dispersion.

[0085] Using a centrifugal separator, centrifugation was performed at a rotation speed of 3000 rpm for 10 minutes, and the precipitate was recovered from the obtained copper dispersion liquid. This precipitate was dispersed in 30 g of distilled water, and the aggregate was precipitated again by centrifugation to separate the precipitate. Thereafter, the obtained precipitate was heated at 80° C. for 60 minutes under a reduced pressure of -35 kPa to volatilize and slowly remove residual water, thereby obtaining copper particles (A) whose particle surfaces were surface-mod...

example 2

[0089] The same procedure as Example 1 was performed except that the copper particles were changed to copper particles with an average particle size of 7 μm (manufactured by NIPPON ATOMIZED METAL POWDERS CORPORATION, trade name: AFS-Cu), and the nickel powder was changed to an average particle size of 0.5 μm. A copper paste is obtained. The value of the average particle diameter of the nickel powder (particle) of (B) component / the average particle diameter of the copper particle of (A) component was 0.07.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com