Method for testing aging resistance of nitride fluorescent powder

A technology of nitride phosphors and testing methods, applied in fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of high testing cost and long time, and achieve the effect of reducing testing cost, speeding up aging process and saving aging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

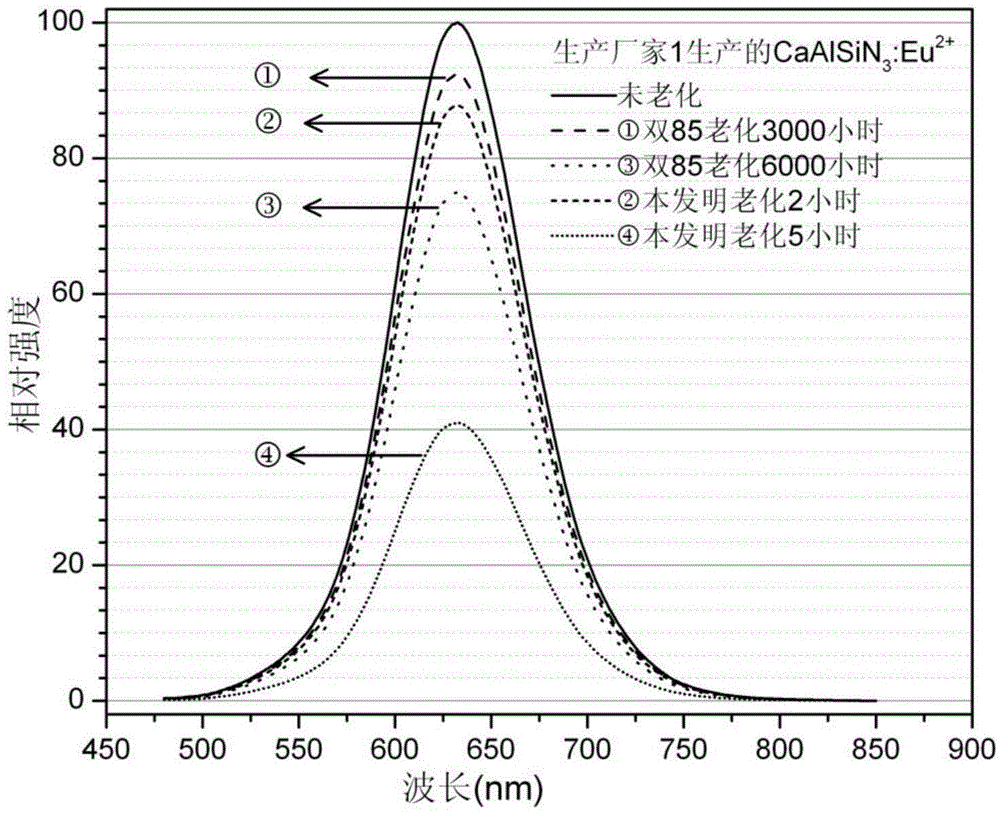

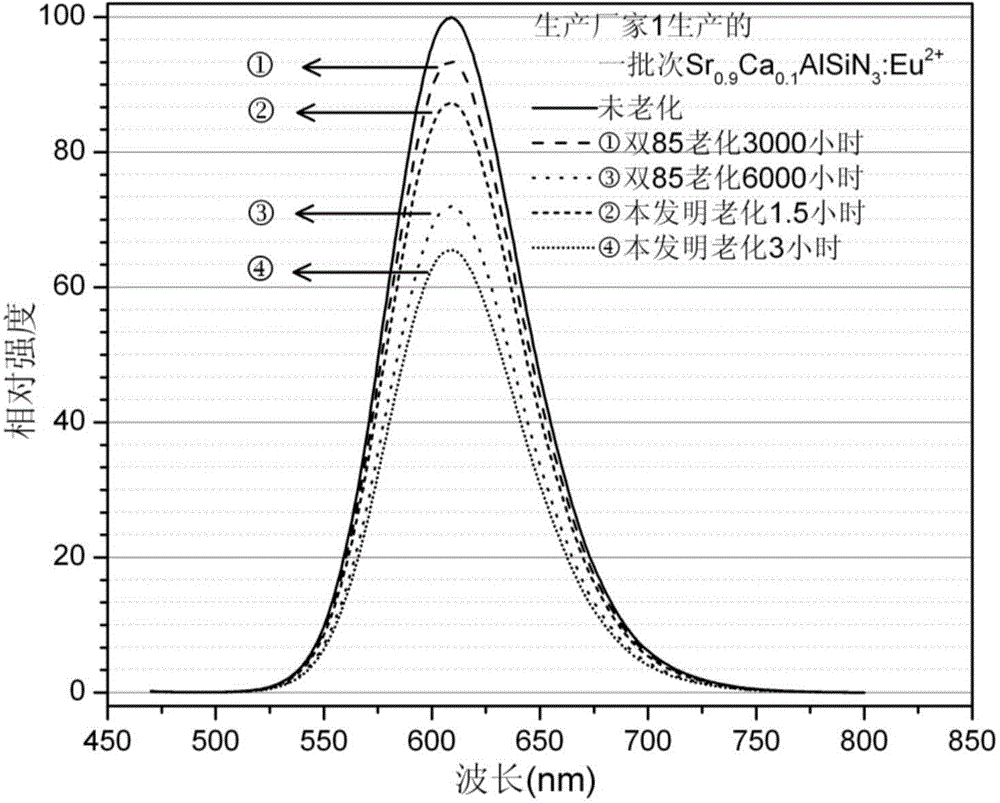

[0042] Take a certain quality of CaAlSiN produced by manufacturer 1 3 :Eu 2+ Phosphor powder was dried in a vacuum oven for 1 hour at a drying temperature of 100°C. After cooling, take some samples and put them into quartz crucibles, put them into a double 85 aging box for aging, the aging conditions are humidity 85%, temperature 85 ℃, aging time is 3000 hours and 6000 hours respectively. After aging, the sample cooled to room temperature was taken out, and placed in a vacuum oven for 6 hours to vacuum dry at 60°C; after the sample was cooled, the sample cooled to room temperature was taken out. The relative intensity values of the emission spectra of the phosphor powder before and after aging were tested respectively. The excitation wavelength during the test is 450nm, the accelerating voltage is 700V, the test scanning speed is 240nm / min, and the excitation and emission slits are both 0.2nm.

reference example 2

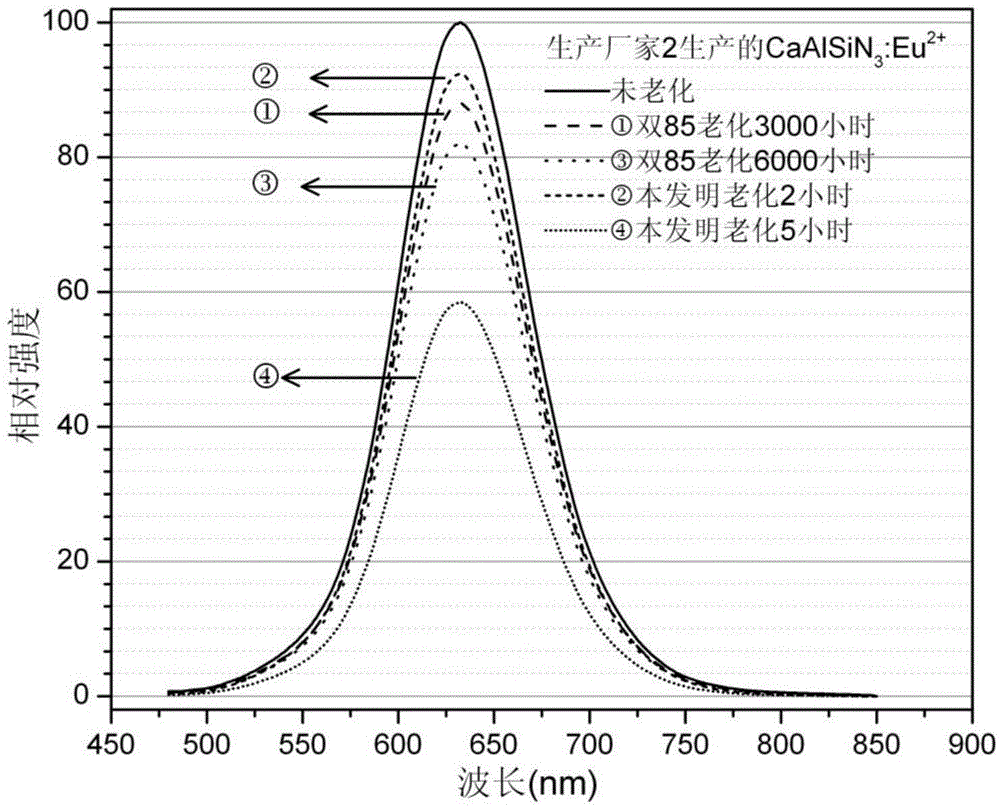

[0044] Take a certain quality of CaAlSiN produced by manufacturer 2 3 :Eu 2+Phosphor powder was dried in a vacuum oven for 1 hour at a drying temperature of 100°C. After cooling, take some samples and put them into quartz crucibles, put them into a double 85 aging box for aging, the aging conditions are humidity 85%, temperature 85 ℃, aging time is 3000 hours and 6000 hours respectively. After aging, the sample cooled to room temperature was taken out, and dried in a vacuum oven for 6 hours at a drying temperature of 60°C; after the sample was cooled, the sample cooled to room temperature was taken out. The relative intensity values of the emission spectra of the phosphor powder before and after aging were tested respectively. The excitation wavelength during the test is 450nm, the accelerating voltage is 700V, the test scanning speed is 240nm / min, and the excitation and emission slits are both 0.2nm.

Embodiment 1

[0046] Take a certain quality of CaAlSiN produced by manufacturer 1 3 :Eu 2+ Phosphor powder was dried in a vacuum oven for 1 hour at a drying temperature of 100°C. After cooling, take some samples and put them into quartz crucibles, put them into the aging equipment 000 for aging, the aging conditions are 100% humidity, 210°C, and the aging time is 2 hours and 5 hours respectively. After aging, the sample cooled to room temperature was taken out, and placed in a vacuum oven for 6 hours to be vacuum-dried at 60° C.; the sample cooled to room temperature after drying was taken out. The relative intensity values of the emission spectra of the phosphor powder before and after aging were tested respectively. The excitation wavelength during the test is 450nm, the accelerating voltage is 700V, the test scanning speed is 240nm / min, and the excitation and emission slits are both 0.2nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com