A kind of production method of trehalose

A production method, trehalose technology, applied in the direction of sugar derivatives, sugar derivatives, sugar derivatives preparation, etc., can solve the problems of difficult processing, high cost, and by-products, etc., to achieve short process and operability Strong, high raw material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

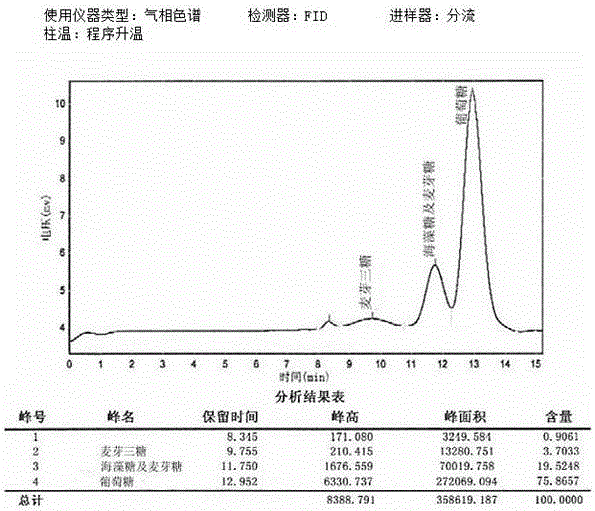

[0053] Example 1 Chromatographic separation 1

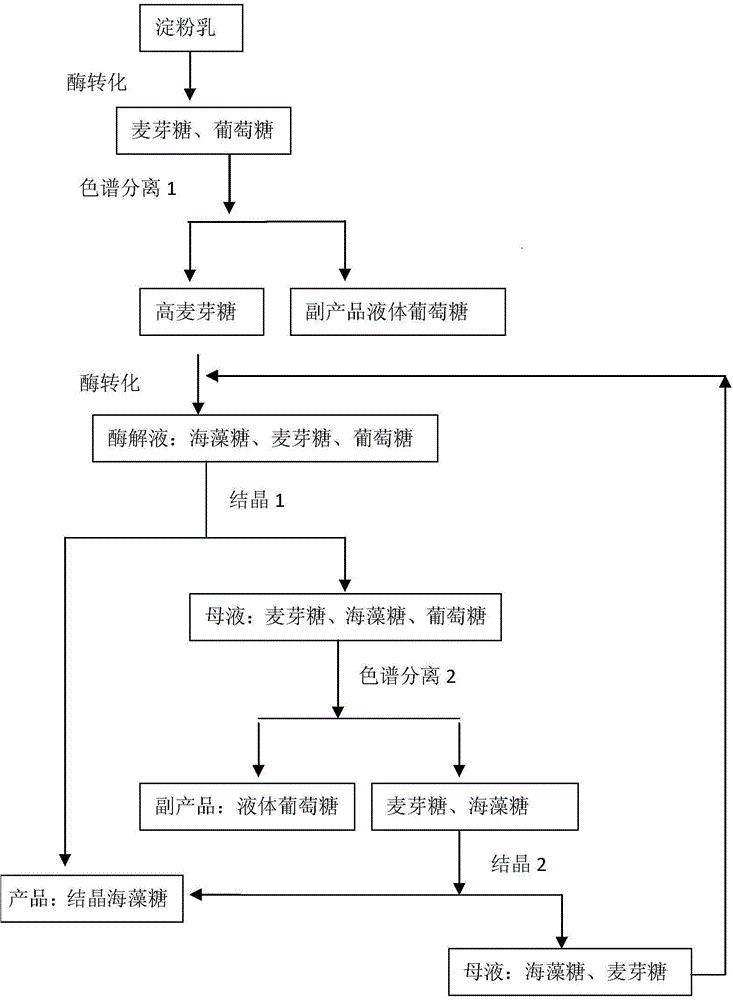

[0054] The trehalose enzymatic hydrolyzate prepared from starch or maltose is decolorized, ion-exchanged, and concentrated to obtain a refined enzymolyzate with a mass percentage concentration of 50-60wt%. The enzymolysis solution enters the first set of chromatographic separation system for separation. The chromatographic separation system uses sequential simulated moving bed chromatographic separation technology, which has the characteristics of high degree of automation, easy operation, high separation strength and high concentration of separated products.

[0055] According to the method of the present invention, the separation agent used in chromatographic separation 1 and chromatographic separation 2 is calcium-type cation separation resin or calcium-type cation molecular sieve, and is loaded into a sequential simulated moving bed chromatographic separation device. There are finished separating agents on the market with st...

Embodiment 2

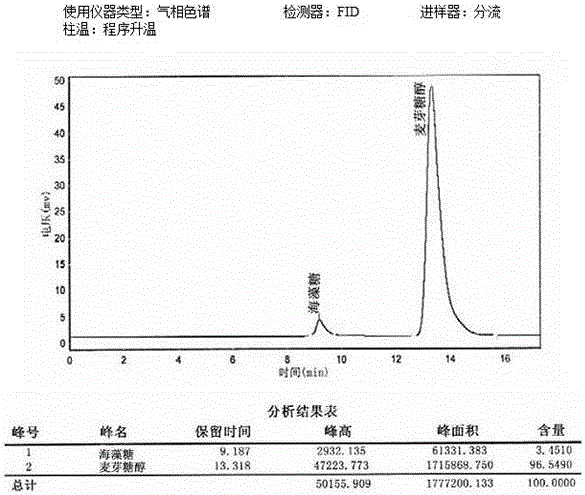

[0058] Example 2 Hydrogenation

[0059] Maltose in the extract is reducing, while trehalose is a non-reducing sugar. Hydrogenate the mixed solution at 100-140°C, 4MPa-12MPa, in the presence of a nickel catalyst, the maltose is hydrogenated and reduced to maltitol, but the trehalose is not hydrogenated, so a hydrogenated mixed solution containing maltitol and trehalose is obtained. Both maltitol and trehalose are products with high added value.

Embodiment 3

[0060] Embodiment 3 Chromatographic separation 2

[0061] The hydrogenated mixed solution containing maltitol and trehalose is decolorized, ion-exchanged, and concentrated to a mass percentage concentration of 50-60 wt%. The peak times of maltitol and trehalose on the chromatogram are quite different, so they can be separated by chromatographic methods more easily. The hydrogenated liquid mixture enters the second chromatographic separation system for separation. The chromatographic separation system uses sequential simulated moving bed chromatographic separation technology. The separation agent used is calcium-type cation separation resin or calcium-type cation molecular sieve, which is installed in a sequential simulated moving bed chromatographic separation device. There are finished separating agents on the market with stable performance. The eluent used is purified water, namely deionized pure water or reverse osmosis pure water, which is economical and easy to obtain. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com