A kind of method of cyclohexane oxidation

A technology for oxidizing cyclohexane and cyclohexane, which is applied in the field of cyclohexane oxidation, can solve the problems of low cyclohexane conversion rate and cyclohexanol selectivity, and achieve the effects of environmental friendliness, high conversion rate and easy production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

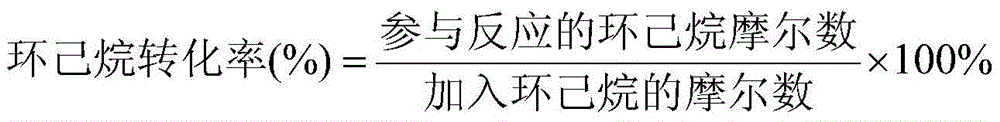

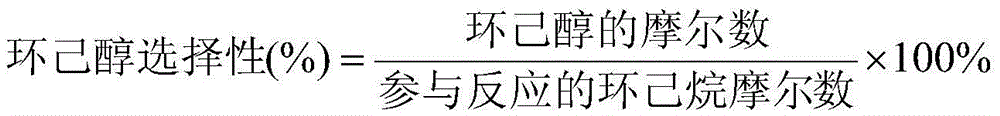

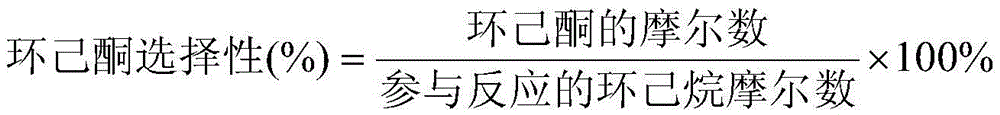

[0035] Cyclohexane, hydrogen peroxide (in this example, hydrogen peroxide is provided in the form of 30% by weight hydrogen peroxide aqueous solution, the following examples are similar), liquid ammonia, solvent methanol and catalyst (TS-1) according to the cyclohexane The molar ratio of hexane to hydrogen peroxide is 1:2, the molar ratio of liquid ammonia to hydrogen peroxide is 0.05:1, the weight ratio of solvent methanol to catalyst is 20:1, and the weight ratio of cyclohexane to catalyst is 20: 1. Carry out the reaction at a temperature of 30°C and a pressure of 1.5MPa.

[0036] The results of the reaction for 6 hours were as follows: the conversion rate of cyclohexane was 47%, the selectivity of cyclohexanol was 64%, and the selectivity of cyclohexanone was 34%.

Embodiment 2

[0041] Mix cyclohexane, hydrogen peroxide, liquid ammonia, solvent methanol and catalyst (TS-1) according to the molar ratio of cyclohexane to hydrogen peroxide is 1:2, and the molar ratio of liquid ammonia to hydrogen peroxide is 0.005:1 , the weight ratio of the solvent methanol to the catalyst is 120:1, the weight ratio of cyclohexane to the catalyst is 40:1, and the reaction is carried out at a temperature of 30° C. and a pressure of 1.5 MPa.

[0042] The results of the reaction for 2 hours were as follows: the conversion rate of cyclohexane was 28%, the selectivity of cyclohexanol was 63%, and the selectivity of cyclohexanone was 36%.

Embodiment 3

[0047] Mix cyclohexane, hydrogen peroxide, liquid ammonia, solvent acetone and catalyst (TS-1) according to the molar ratio of cyclohexane to hydrogen peroxide is 1:5, and the molar ratio of liquid ammonia to hydrogen peroxide is 0.01:1 , the weight ratio of the solvent acetone to the catalyst is 200:1, the weight ratio of cyclohexane to the catalyst is 80:1, and the reaction is carried out at a temperature of 60° C. and a pressure of 1.0 MPa.

[0048] The results of the reaction for 4 hours were as follows: the conversion rate of cyclohexane was 81%, the selectivity of cyclohexanol was 68%, and the selectivity of cyclohexanone was 31%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com