Lens driving device, camera, and camera-equipped cellular phone

A lens driving device and lens technology, applied to cameras, electromechanical devices, focusing devices, etc., can solve problems such as difficulty in use, time-consuming spring attachment, etc., and achieve the effect of easy selection and design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

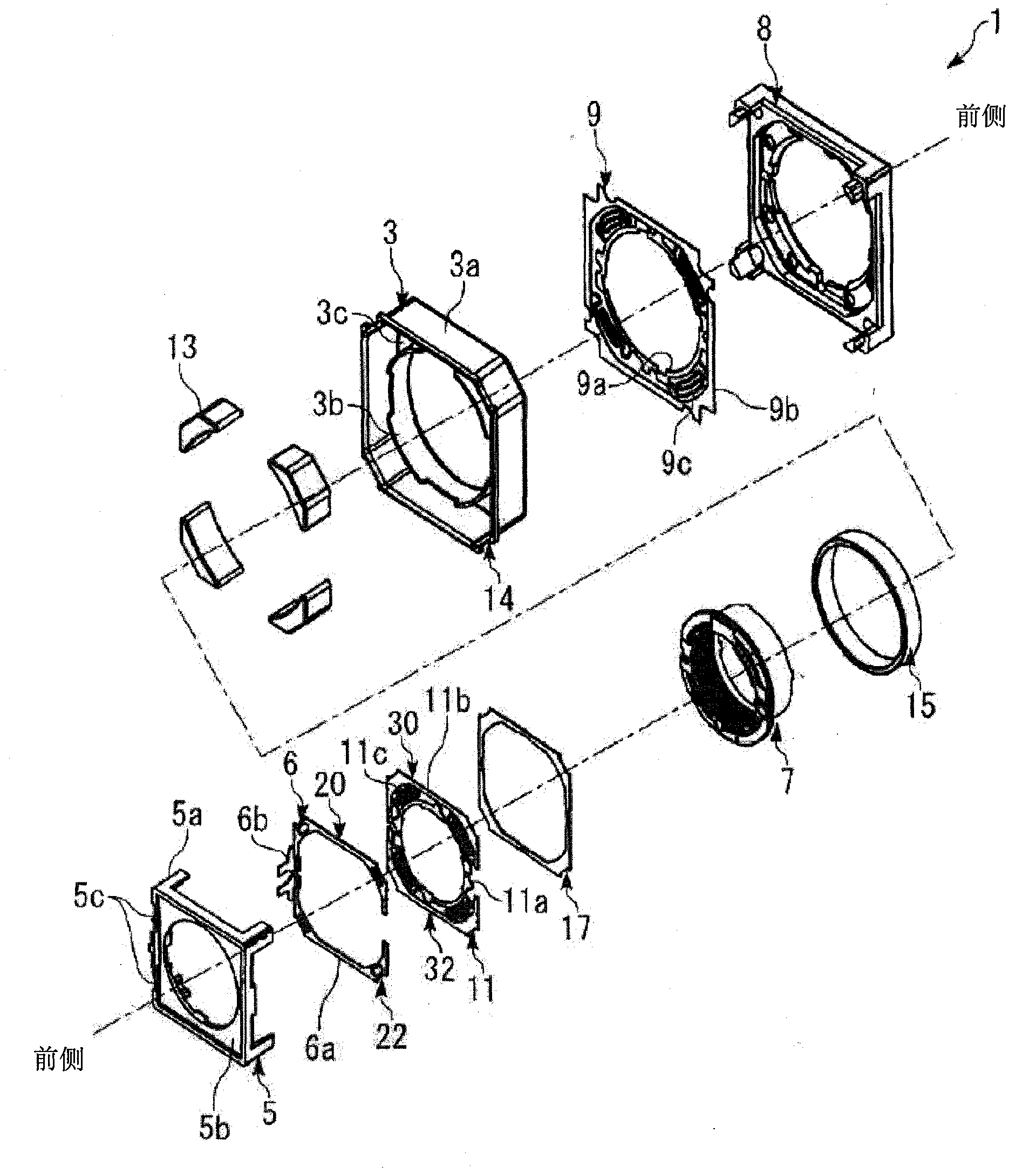

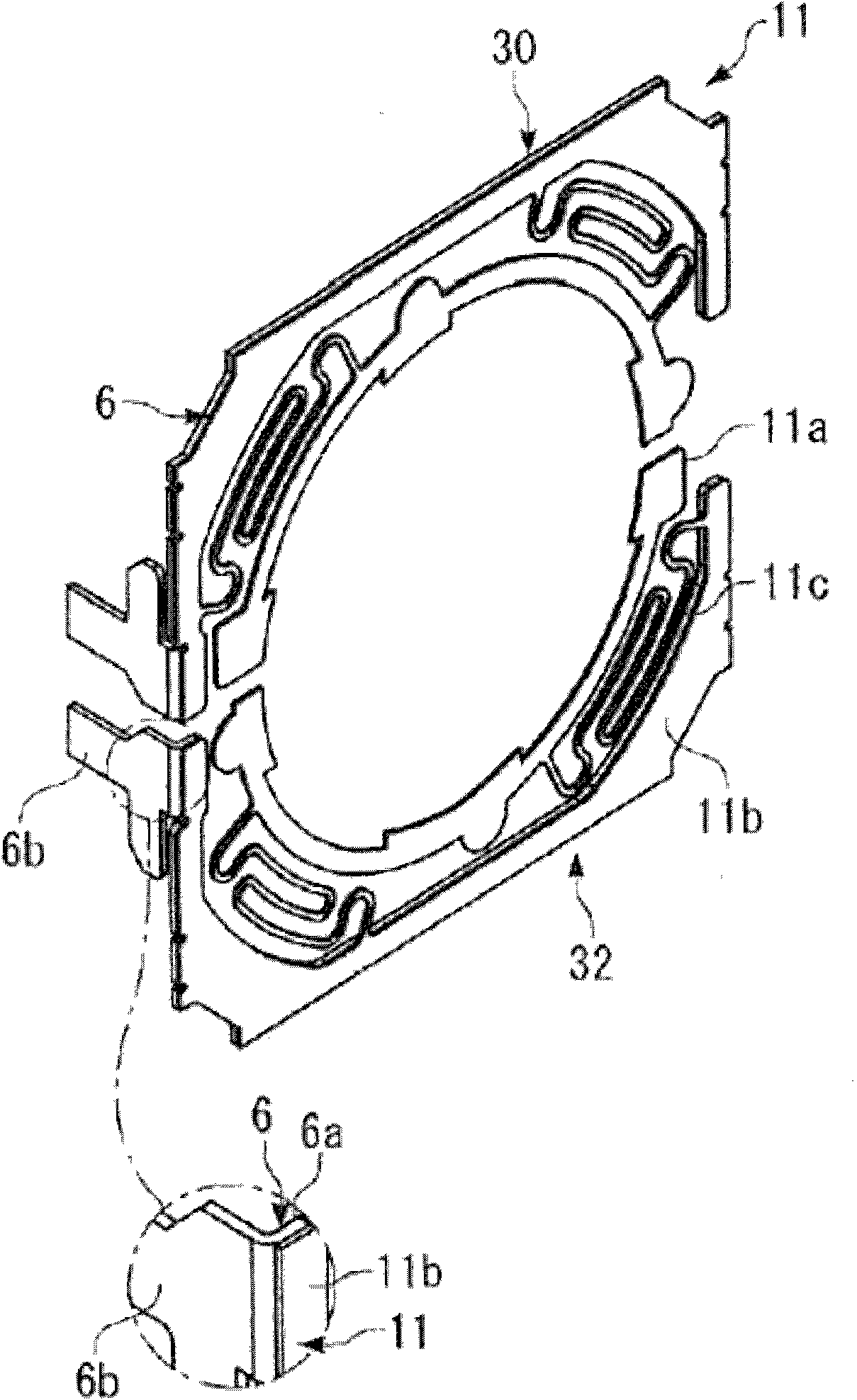

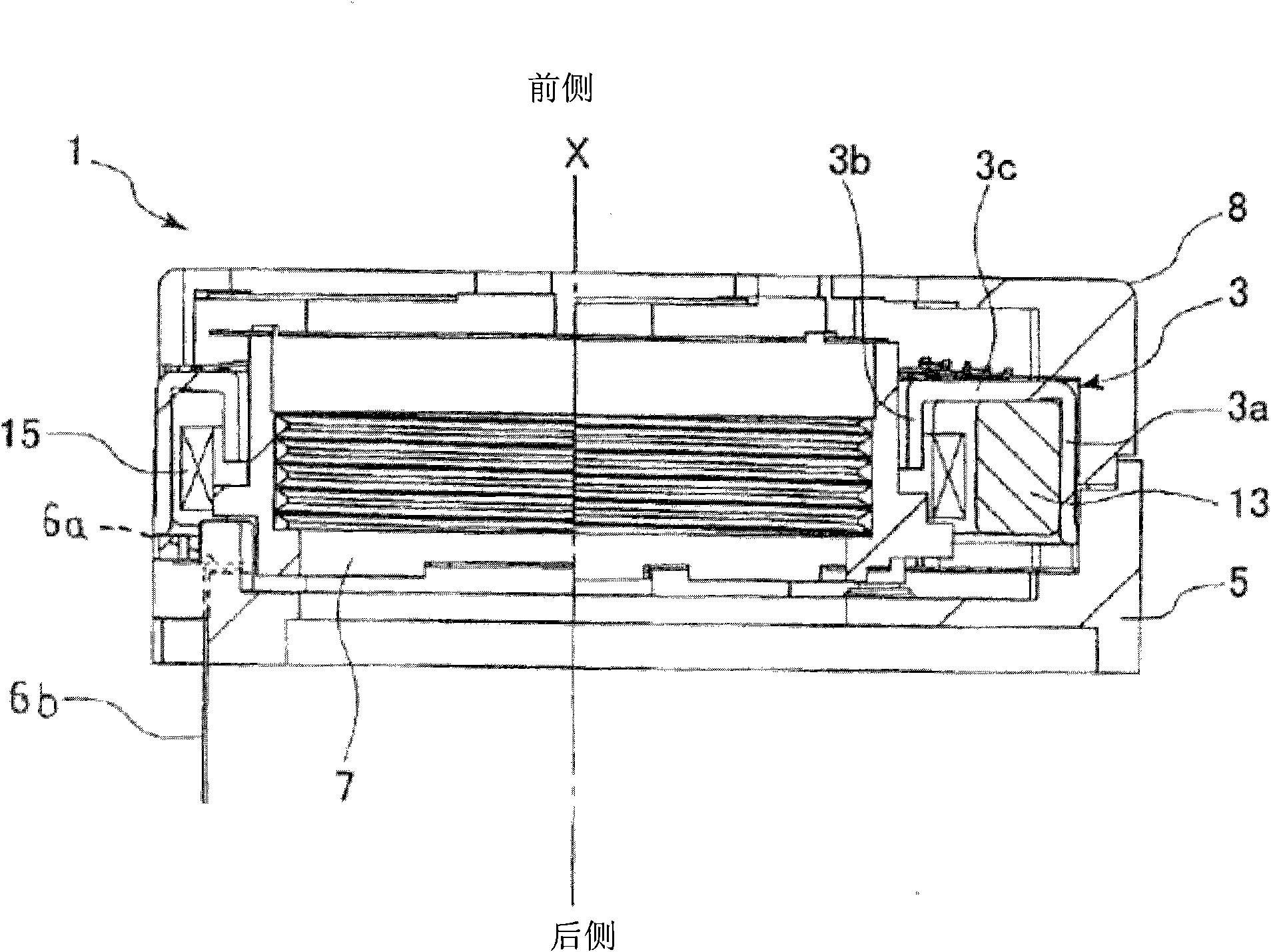

[0028] Hereinafter, embodiments of the present invention will be described with reference to the drawings. The lens driving device 1 related to the first embodiment is a lens driving device of an auto-focus camera function machine assembled in a mobile phone. The lens driver such as figure 1 and image 3 As shown, it has an annular ring mouth 3, a lens support body 7, a front side spring 9, a rear side spring (spring) 11, a base 5 (frame) arranged on the rear side of the ring mouth 3, and a frame 8 on the front side of the A coil 15 is fixed to the outer periphery of the lens support 7 , an insulator (spacer) 17 is disposed between the ring 3 and the rear spring 11 , and a terminal member 6 is disposed between the rear spring 11 and the base 5 . The lens driving device 1 is about 10mm in width and 3.5mm in height, which is a very small structure.

[0029] Seen from the front side, the ring mouth 3 is quadrangular in plan view of its outer periphery, and circular in plan vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com