Titanium concentrate ball-milling system

A titanium concentrate and ball milling technology, which is applied in the fields of dust removal, cleaning methods and appliances, and grain processing, can solve the problems of health impact on workers, flying titanium concentrate powder, and high power consumption during operation, so as to reduce dust entering the air, The effect is good and the effect of improving the efficiency of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

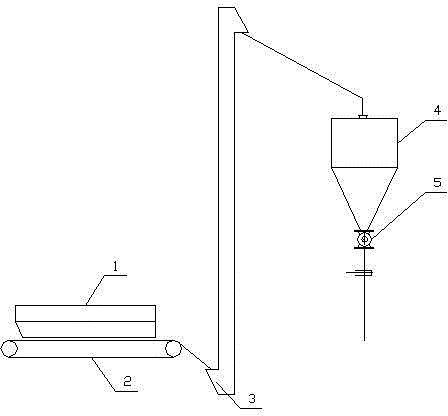

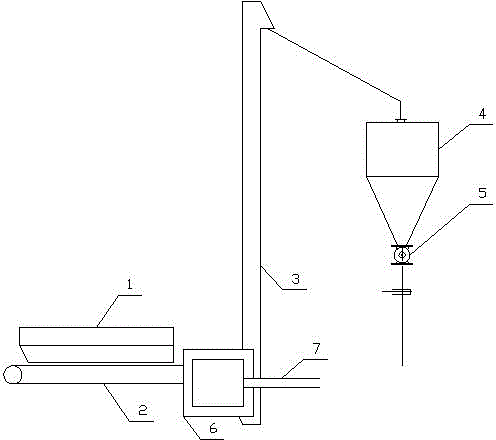

[0019] The titanium concentrate ball mill system of the present invention comprises a raw material belt hopper, a raw material belt conveyor, a raw material bucket elevator, a ball mill system fan and a bag filter, the raw material belt conveyor is arranged below the raw material belt hopper, and the raw material hopper belt conveyor and Cooperate with the raw material bucket elevator, the connection between the raw material belt conveyor and the raw material bucket elevator is equipped with a collection device. The collection device includes a collection end and a collection pipe. One end of the collection pipe is connected to the collection end, and the other end is connected to the fan of the ball mill system. The ball mill system The fan is connected with the bag filter. A collection device is installed at the junction of the belt conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com