Acidolysis pre-mixing system for reducing formation of solid phase by mineral powder and concentrated sulfuric acid

A technology of concentrated sulfuric acid and solid-phase substances, which is applied to mixers, dissolvers, and mixers with rotating stirring devices, which can solve the problems of high labor intensity and harsh working environment, reduce labor intensity and ensure normal operation , the effect of reducing the formation of solid phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

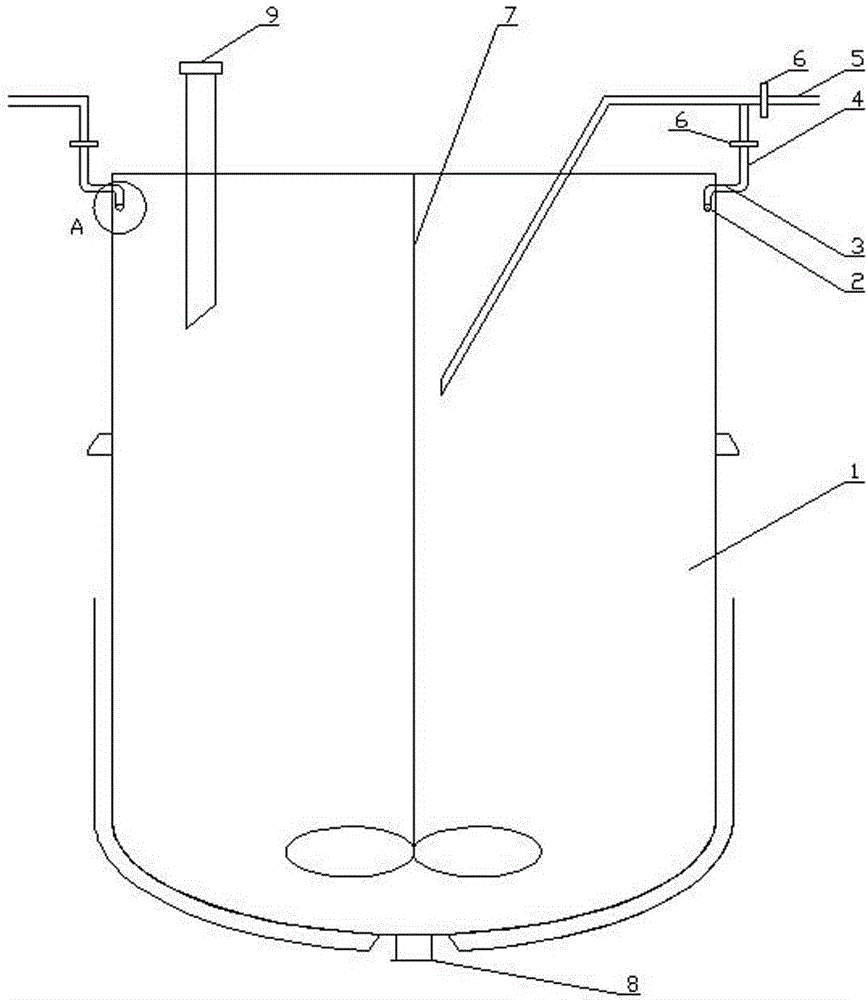

[0021] The acidolysis premixing system for reducing the formation of solids from mineral powder and concentrated sulfuric acid of the present invention includes a premixing tank, a stirring mechanism, a bottom valve and a main pipeline of sulfuric acid, the stirring mechanism is located inside the premixing tank, and the bottom valve is located in the premixing tank At the bottom, one end of the sulfuric acid main pipeline is connected to the external sulfuric acid source, and the other end is connected to the premix tank; Spray holes in the inner wall. The inner wall of the premixing tank can be automatically cleaned through the spray pipe, reducing the formation of solids, preventing the solids from falling to the bottom of the premixing tank from time to time, and blocking the discharge valve at the bottom; thus ensuring the normal operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com