Intermediate film for laminated glass, and laminated glass

A technology of laminated glass and interlayer film, which can be used in glass/slag layered products, applications, household appliances, etc., and can solve the problem of discoloration of the interlayer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

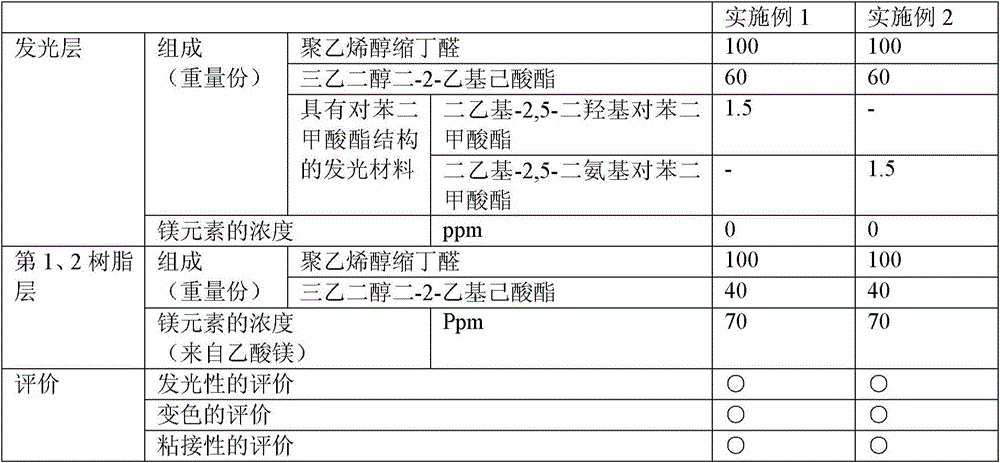

Embodiment 1

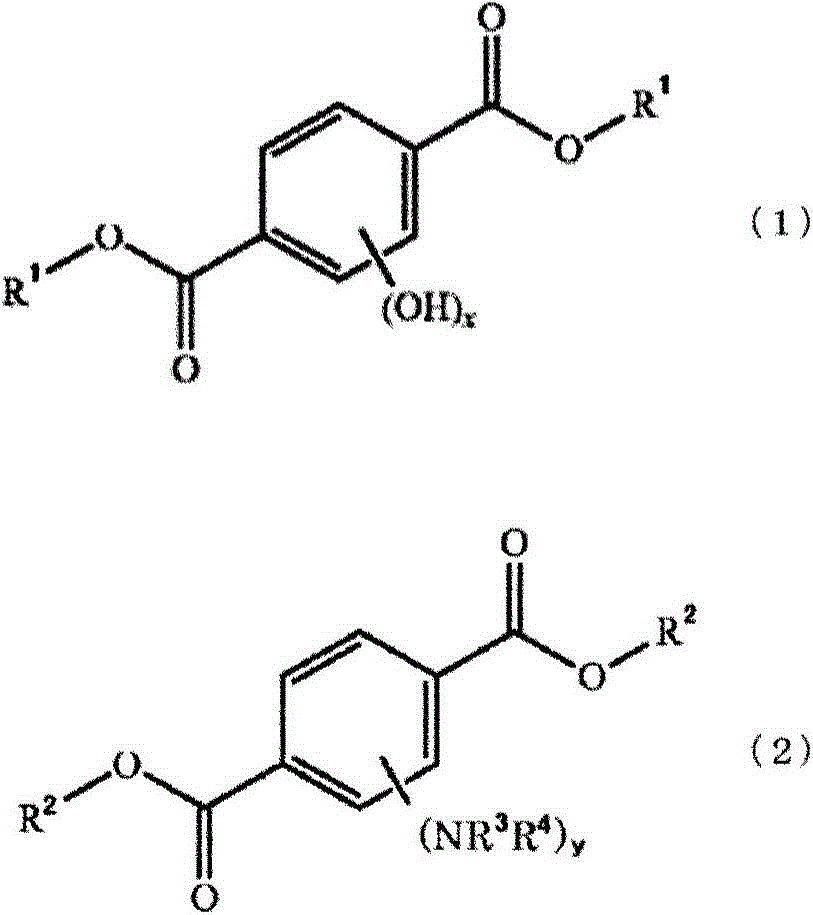

[0088] (1) Resin composition for forming light-emitting layer

[0089] 60 parts by weight of triethylene glycol di-2-ethylhexanoate (3GO) is added as a luminescent material having a terephthalate structure, which is a compound having a structure represented by the above general formula (1). A luminescent plasticizer solution was prepared using 1.5 parts by weight of ethyl-2,5-dihydroxyterephthalate ("diethyl 2,5-dihydroxyterephthalate" manufactured by Aldrich). The total amount of the obtained plasticizer solution and the polyvinyl butyral obtained by acetalizing polyvinyl alcohol having a degree of polymerization of 2300 with n-butyraldehyde (13 mol % of acetyl groups, 22 mol % of hydroxyl groups) %, butyralization degree 65 mol%) 100 parts by weight were fully kneaded with a stirring roller to prepare a resin composition for forming a light-emitting layer.

[0090] (2) Resin composition for forming the first and second resin layers

[0091] Magnesium acetate was added to 4...

Embodiment 2

[0097] As a luminescent material having a terephthalate structure, instead of diethyl-2,5-dihydroxy terephthalate (manufactured by Aldrich "2 , 5-dihydroxy terephthalate ") 1.5 parts by weight, use the compound that has the structure represented by the above-mentioned general formula (2), that is, diethyl-2,5-diamino terephthalate ( Aldrich) was 1.5 parts by weight, and the interlayer film for laminated glass and laminated glass were obtained in the same manner as in Example 1.

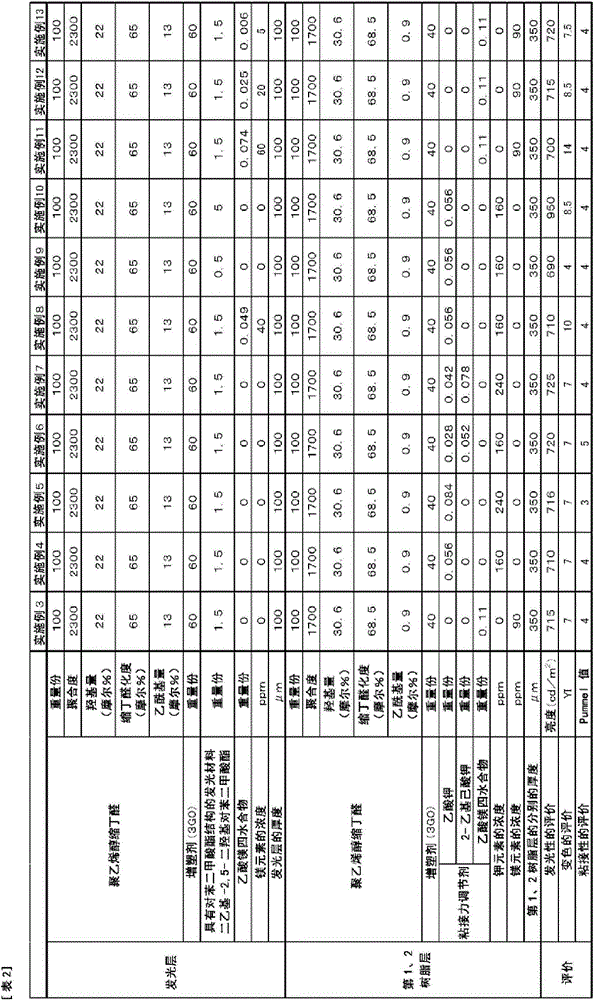

Embodiment 3~25

[0098] (Examples 3-25, Comparative Examples 1-5)

[0099] An interlayer film for laminated glass and a laminated glass were obtained in the same manner as in Example 1, except that the resin compositions and thicknesses for forming the light emitting layer and the first and second resin layers were changed as shown in Tables 2 to 4.

[0100] (evaluate)

[0101] The laminated glasses obtained in Examples 1 to 25 and Comparative Examples 1 to 5 were evaluated by the following methods. The results are shown in Tables 1-4.

[0102] (1) Evaluation of Luminescence

[0103] The obtained laminated glass was irradiated with light to the entire surface of the laminated glass in a dark room using a High Power xenon light source (manufactured by Asahi Spectro Co., Ltd., product number REX-250, irradiation wavelength: 405 nm). When observed visually, the case where light emission was confirmed in the central portion of the laminated glass was evaluated as "◯", and the case where light e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of acetalization | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com