3D printing monitoring error correction method based on three views

A technology of 3D printing and error correction method, applied in the direction of digital output to printing unit, hardware monitoring, instruments, etc., can solve the problems such as the lack of 3D printing monitoring and error correction technology, the impact of 3D entity quality, etc., to ensure the printing effect, Low cost, reduce unqualified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail in conjunction with the accompanying drawings.

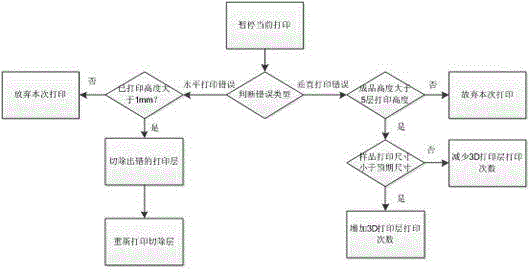

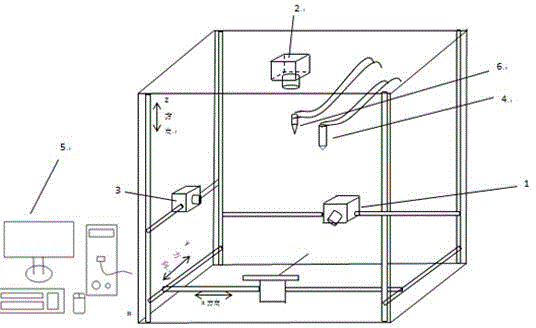

[0032] The present invention will be further described in detail through specific examples below. refer to Figure 1 to Figure 3 , the present invention relates to a 3D printing monitoring and error correction method based on three views, which is carried out according to the following steps:

[0033] 1) Provide a system that includes three cameras that monitor three viewing angles, a computer and a horizontal cutting knife, the computer has an image recognition module for processing the camera picture information, and the cameras are perpendicular to each other to monitor samples Front view, top view, left view, the horizontal cutting knife is used to cut off the printing layer to be processed;

[0034] 2) Process the processing model and obtain the expect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com