Nano fiber coupling structure gas sensitive material and preparation method and application thereof

A gas-sensitive material and nanofiber technology, applied in nanotechnology, nanotechnology, material resistance, etc., can solve the problems of long response recovery time, poor selectivity, and low sensitivity, and achieve simple and convenient production equipment, improved sensitivity, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

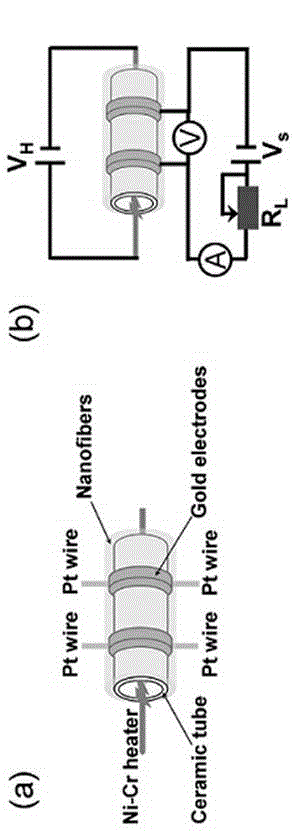

Embodiment 1

[0053] In a 50 mL Erlenmeyer flask, add 0.7 g of polyacrylonitrile (PAN) into 9.3 mL of N,N~dimethylformamide (DMF), stir at 60 °C for 8 h until the solution is completely clear, and cool to room temperature.

[0054] Put the dissolved PAN solution into the spinneret of the electrospinning equipment. The inner diameter of the spinneret head is 1 mm. The aluminum sleeve is used as the anode, and the aluminum foil is used as the cathode plate to receive the product. The distance between the two electrodes is 20 cm. Electrospinning was performed at a voltage of 15 kV. This results in polyacrylonitrile nanofibers on the cathode receiver plate.

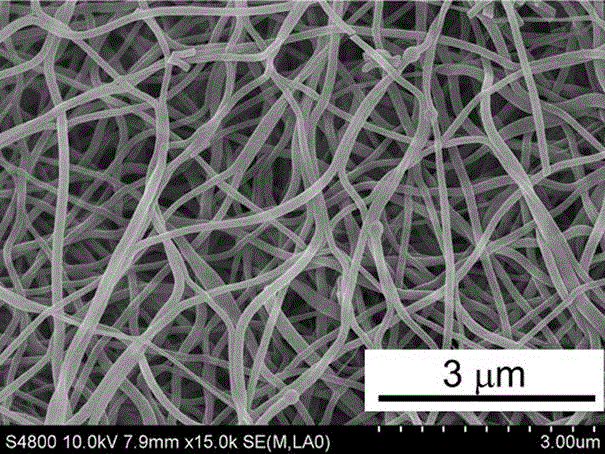

[0055] The PAN nanofibers were placed in the air for 20 hours to allow the residual solvent in the fibers to evaporate, and then placed in a tube electric furnace, the temperature was raised to 250 °C at a rate of 5 °C / min, and pre-oxidized in the air atmosphere for 2 h. Nitrogen was introduced into the tube furnace, the temperature was r...

Embodiment 2

[0062] Solution preparation, spinning process and carbon fiber sintering process are consistent with Example 1.

[0063] Take a 100 mL beaker, add 40 mL of 10 mM thioglycolic acid solution, weigh 6 mg of carbon nanofibers into the beaker, and sonicate for 1 h, so that the carbon fibers are evenly dispersed in the solution. Then add 0.1 g SnCl to the beaker 2 , 0.5 mL 37% HCl solution, 0.5 g urea, stirred for 10 min. The mixed solution was transferred to a 60 mL hydrothermal reaction kettle, placed in a constant temperature oven at 120°C for 12 hours, the reaction solution was taken out, and the precipitate was separated, washed and dried.

[0064] The assembly process of the gas sensor is consistent with that of Embodiment 1. The optimal operating temperature of the device is still 200 °C, and the response value to 100 ppm hydrogen at this temperature is 7.2.

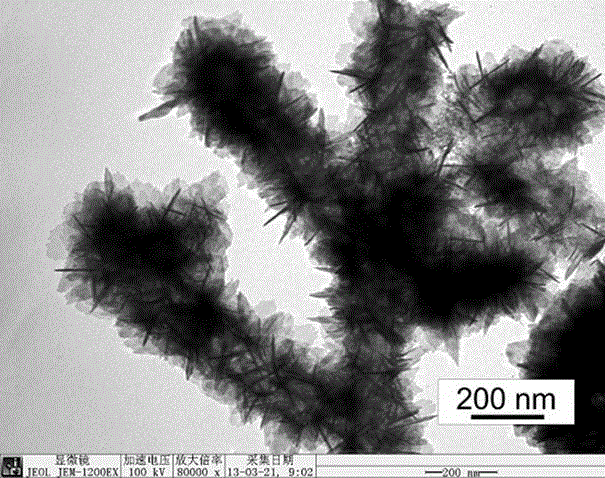

[0065] Such as Figure 4 As shown, the SnO prepared in Example 2 2 / The transmission photo of the carbon nanofib...

Embodiment 3

[0067] Solution preparation, spinning process and carbon fiber sintering process are consistent with Example 1.

[0068] Take a 100 mL beaker, add 40 mL of 10 mM thioglycolic acid solution, weigh 6 mg of carbon nanofibers into the beaker, and sonicate for 1 h, so that the carbon fibers are evenly dispersed in the solution. Then add 0.1 g SnCl to the beaker 2 , 0.5 mL 37% HCl solution, 0.5 g urea, stirred for 10 min. The mixed solution was transferred to a 60 mL hydrothermal reaction kettle, placed in a constant temperature oven at 120 °C for 6 hours, the reaction solution was taken out, and the precipitate was separated, washed and dried.

[0069] The assembly process of the gas sensor is consistent with that of Embodiment 1. The optimal operating temperature of the device is still 200 °C, and the response value to 100 ppm hydrogen at this temperature is 4.2.

[0070] Such as Figure 5 Shown, the SnO that embodiment 3 makes 2 / The transmission photo of the carbon nanofib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com