System evaluation method for block distribution after ore blasting

A system evaluation and degree distribution technology, applied in the direction of material analysis, image analysis, and material analysis through optical means, can solve the problems of extensive promotion restrictions, labor and time-consuming measurement, empirical formula errors, etc., and achieve extensive promotion value, good Economic benefits, the effect of accurate evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

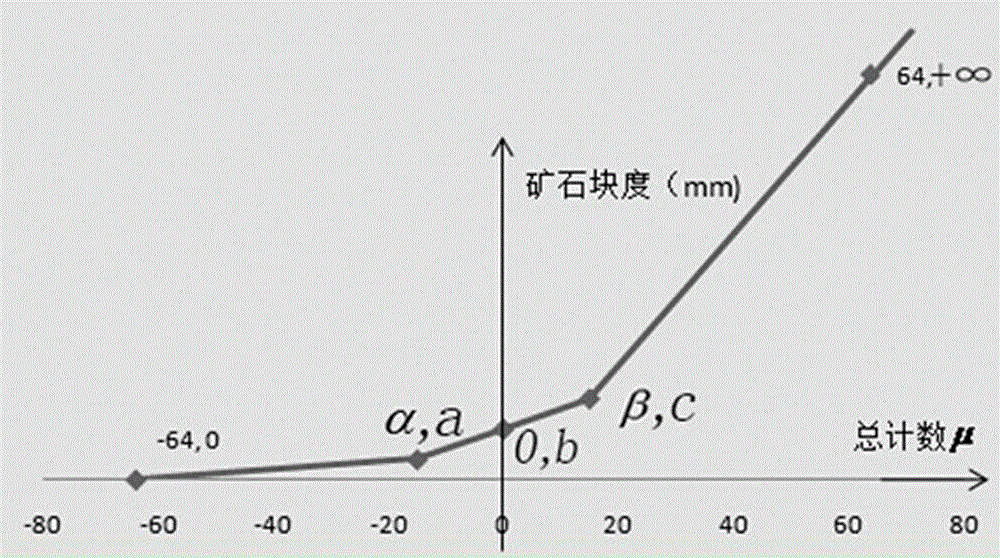

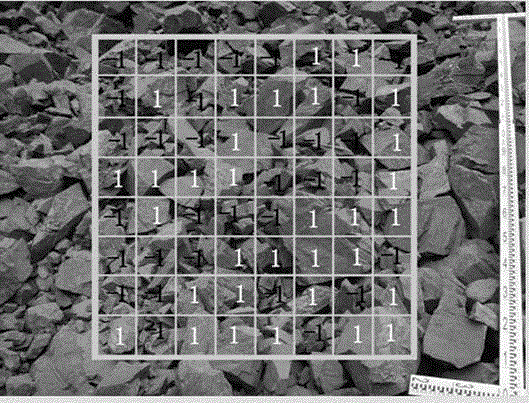

[0041] Such as figure 1 and figure 2 As shown, a photo with a good overall distribution of ore blasting fragmentation is selected, and the 8×8 square grid with the area of each small square of b×b size is used to calculate its value, 32 of the 64 squares in the picture are counted as 1, and 32 are counted as -1, and the total count is 32+(-32)=0, indicating that the blasting fragmentation of the ore is the best blasting fragmentation diameter b that the crusher can accept.

Embodiment 2

[0043] Such as image 3 and Figure 4 As shown in Fig. 1, a selected photo showing a small overall distribution of ore blasting fragmentation size is calculated by using 8×8 square grids with the area of each small square being b×b. value, 23 of the 64 squares in the picture are counted as 1, and 41 are counted as -1, and the total count is 23+(-41)=-18, indicating that the ore blast fragmentation is the minimum ore blast fragment diameter a that the crusher can accept.

Embodiment 3

[0045] Such as Figure 5 and Figure 6 As shown, a selected photo of ore blasting with a smaller overall distribution of block size is calculated by using 8×8 square grids with the area of each small square being b×b. value, 10 of the 64 squares in the picture are counted as 1, 54 are counted as -1, and the total count is 10+(-54)=-44, indicating that the ore blasting block size is smaller than the minimum ore blasting block size diameter a that the crusher can accept. The general announcement is not suitable for entering the crusher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com