Device and method for simulating corrosion and fatigue coupling test on lifting rope under ozone atmosphere environment

A corrosion test and corrosion fatigue technology, applied in interdisciplinary fields, can solve problems such as fatigue tests, and achieve low-cost and environment-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

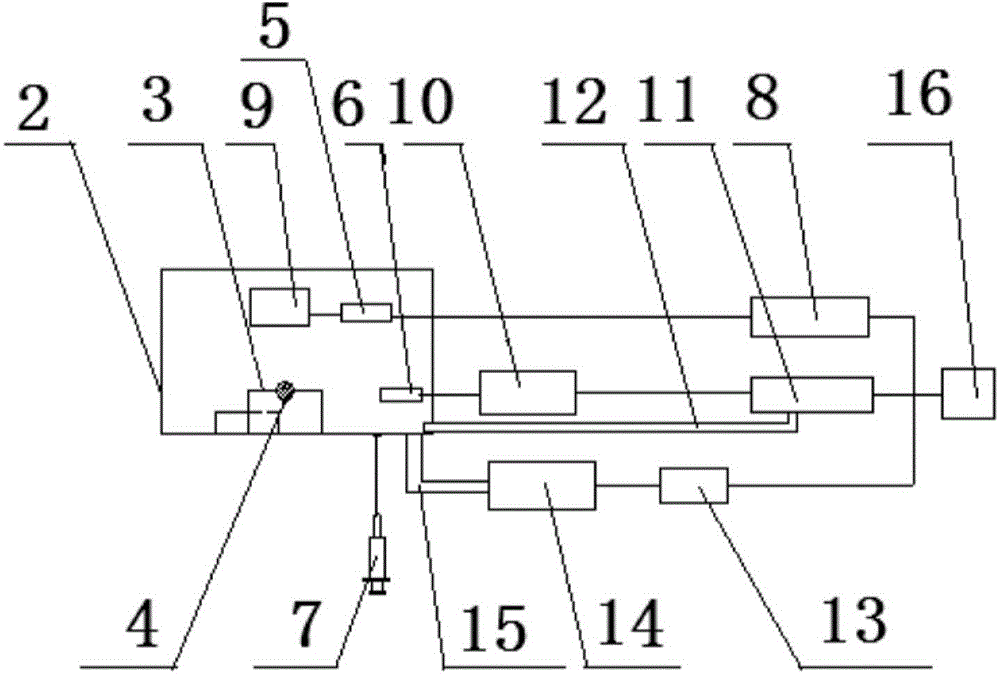

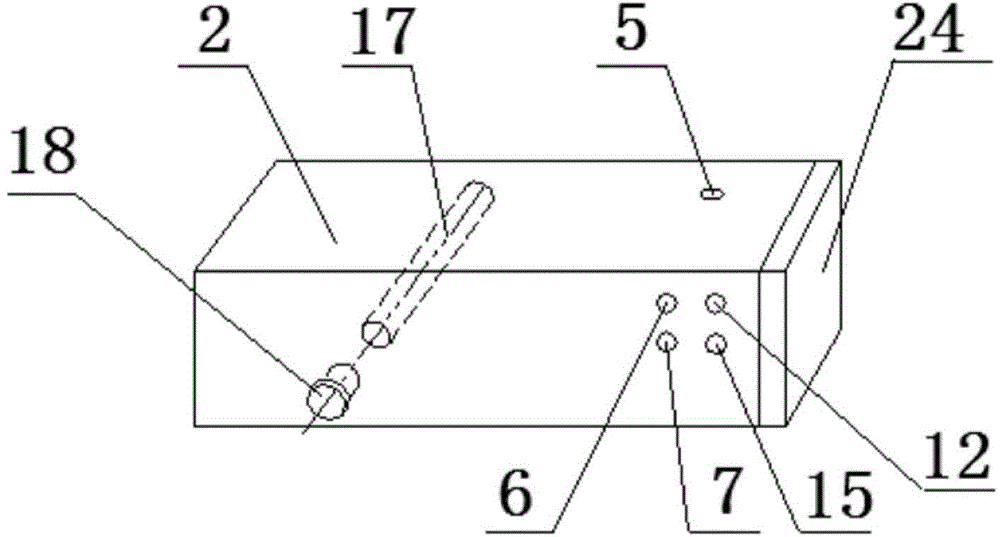

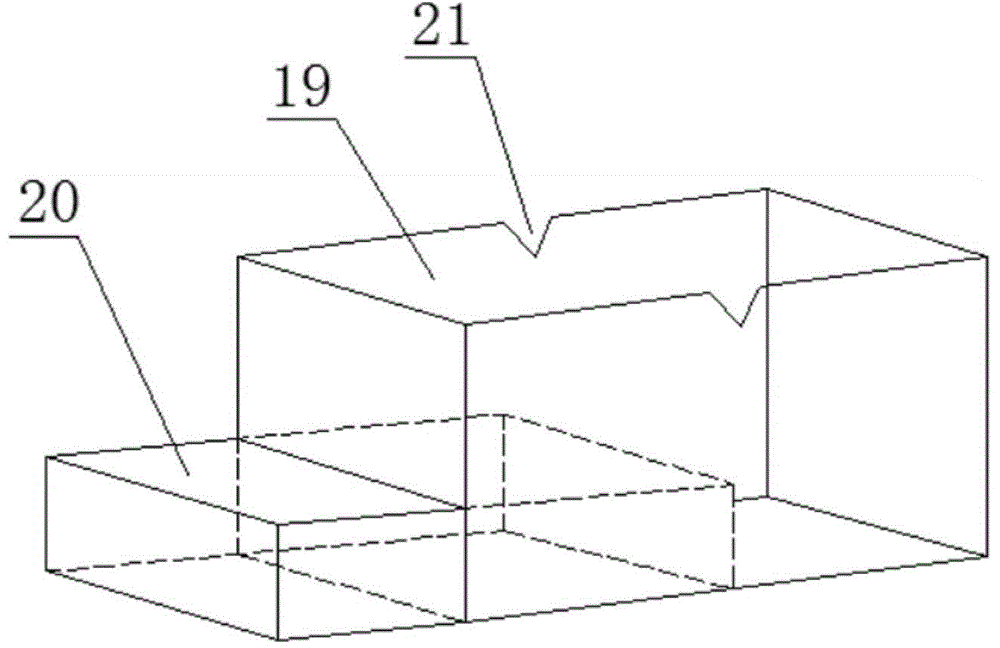

[0036] The invention provides a device for sling corrosion fatigue coupling test simulating ozone atmospheric environment, such as figure 1 As shown, including the corrosion test chamber 2, the corrosion test chamber 2 is provided with a detection and control device; as Figure 4 As shown, there are two iron hoops 22 close to the corrosion test chamber 2, and two telescopic fixing rods 23 are respectively connected to both sides of each iron hoop 22, as shown in FIG. Figure 5 As shown, the telescopic fixed pull rod 23 is connected and fixed to the column 25 of the fatigue testing machine 1; a sample rack 3 is arranged in the corrosion test chamber 2, and a sling test section 4 is arranged on the sample rack 3.

[0037] The detection control device includes a power supply 16, the power supply 16 is respectively connected with a temperature c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com