Low-strength rock sample preparation device with weak interface and sample preparation method

A rock sample and preparation device technology, which is applied in the preparation of test samples, etc., can solve the problems of high damage rate and difficulty in preparing low-strength rock samples, and achieve the effect of low surface damage rate, small damage and good preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

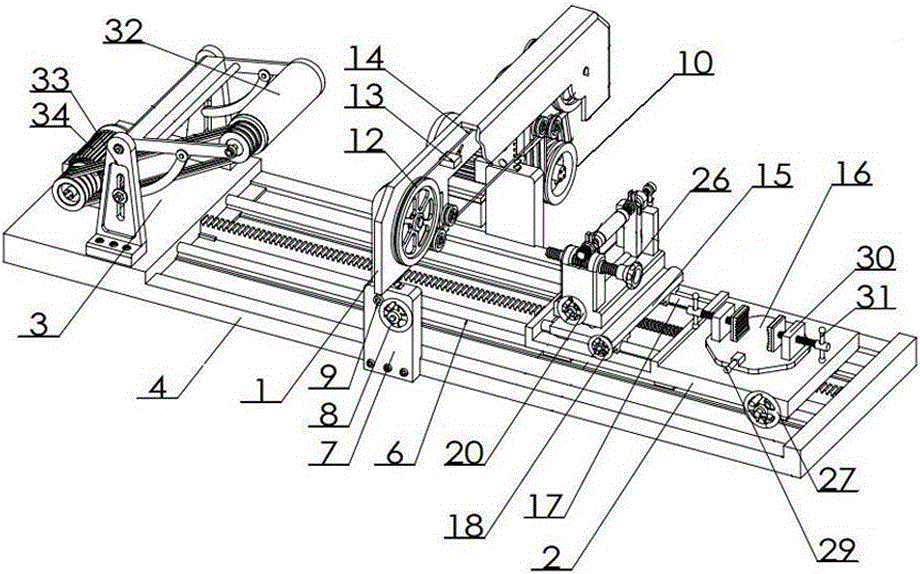

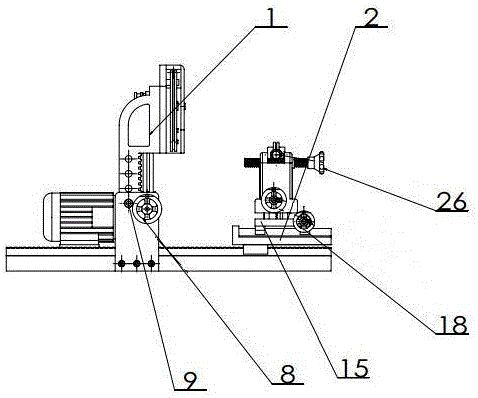

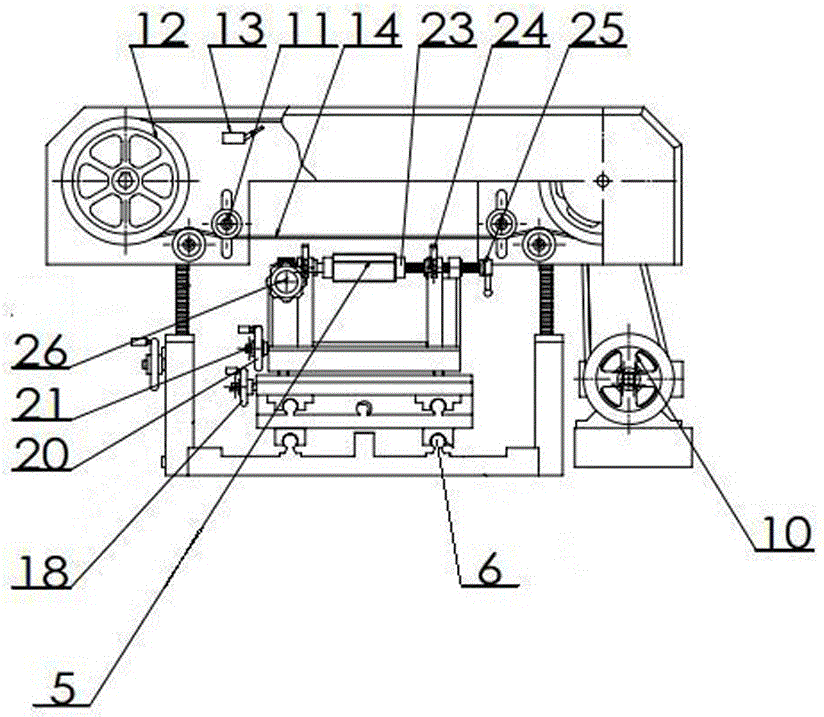

[0049] Such as figure 1 As shown, the low-strength rock sample preparation device with a weak interface is composed of a diamond wire saw machine 1, a workbench 2, and a grinder 3 arranged on a base 4. Refer to Figure 5 , a cutting table 15 and a clamping turntable 16 are set on the workbench 2, and the diamond wire saw machine 1 spans the base 4 through the steel brackets 7 on both sides. The rail 6 passes under the diamond wire saw machine 1, and the workbench 2 can move horizontally on the translation slide rail 6. The workbench 2 can move the cutting table 15 or the clamping turntable 16 to the diamond wire 14 of the diamond wire saw machine respectively. Below, the workbench 2 can also move the cutting table 15 below the grinding cylinder 32 of the grinding machine 3 . The workbench 2 is provided with a propulsion handwheel 27, and the workbench 2 is controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com