System for testing high-temperature pipeline flange under action of outer bending moment

A pipeline flange, testing system technology, applied in the testing of mechanical components, testing of machine/structural components, liquid tightness measurement using liquid/vacuum, etc., can solve deflection, warpage, crack leakage, flange The problem of complex stress changes, etc., achieves the effect of strong guiding significance, high leakage measurement accuracy, and accurate stress measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

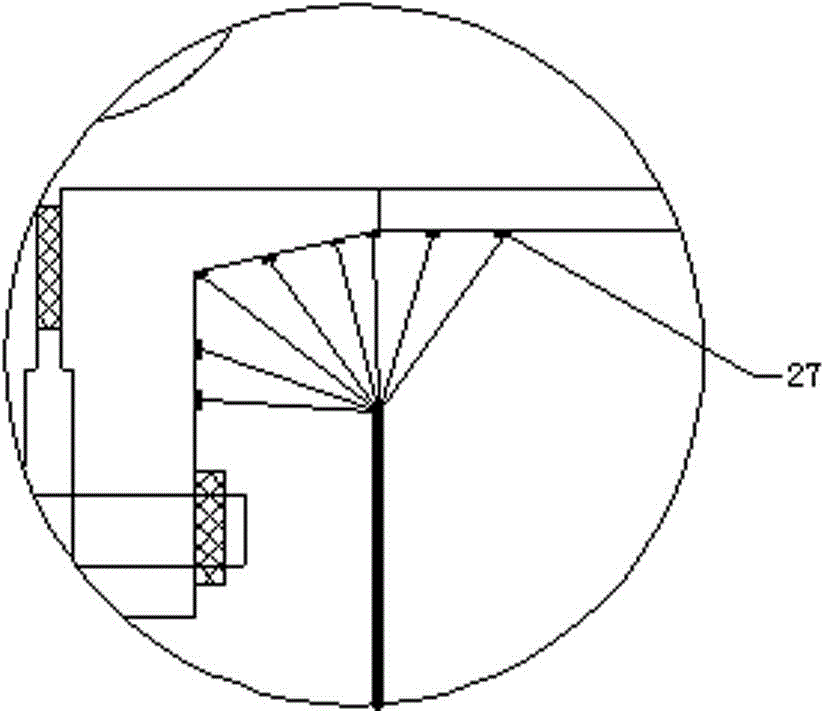

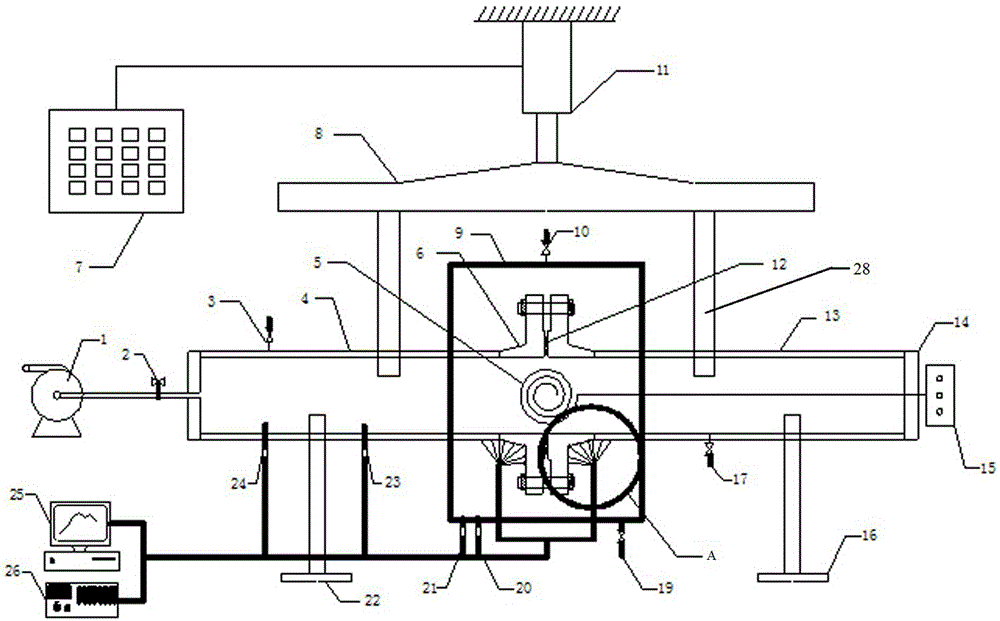

[0018] Such as figure 1 , figure 2 As shown, a high-temperature pipeline flange testing system under the action of external bending moment, it includes a left pipeline 4, a right pipeline 13, and a flange 6 connecting the left pipeline 4 and the right pipeline 13, and the flange 6 is connected by bolts , and use the gasket 12 to seal, the left pipe 4, the right pipe 13, and the flange 6 form a flange cavity to be tested, the left pipe 4 is provided with an exhaust valve 3, and the right pipe 13 is provided with an underflow port valve 17;

[0019] The left pipeline 4 is connected with the pump 1 through the valve 2, and the right pipeline 13 is welded with the blind plate 14; a temperature sensor 23 and a pressure sensor 24 are arranged in the cavity of the flange to be measured, and are controlled by an electric heater electric cabinet 15 The electric heating devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com